Wire tension controller of multi-strand spring digital control lathe

A technology of tension controller and CNC machine tool, which is applied in the direction of manufacturing springs from wires, household appliances, and other household appliances. It can solve problems such as flattening, steel wire elongation, and affecting the quality and service life of finished multi-strand coil springs. The effect of uniform and consistent tension and constant tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

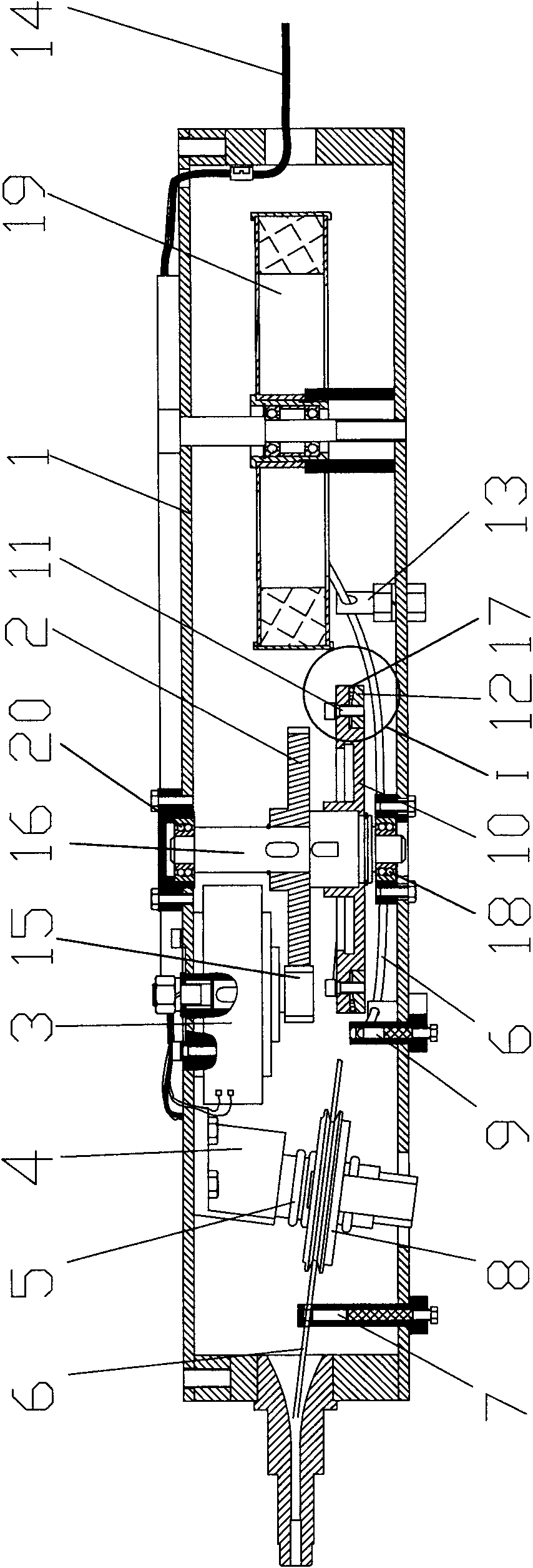

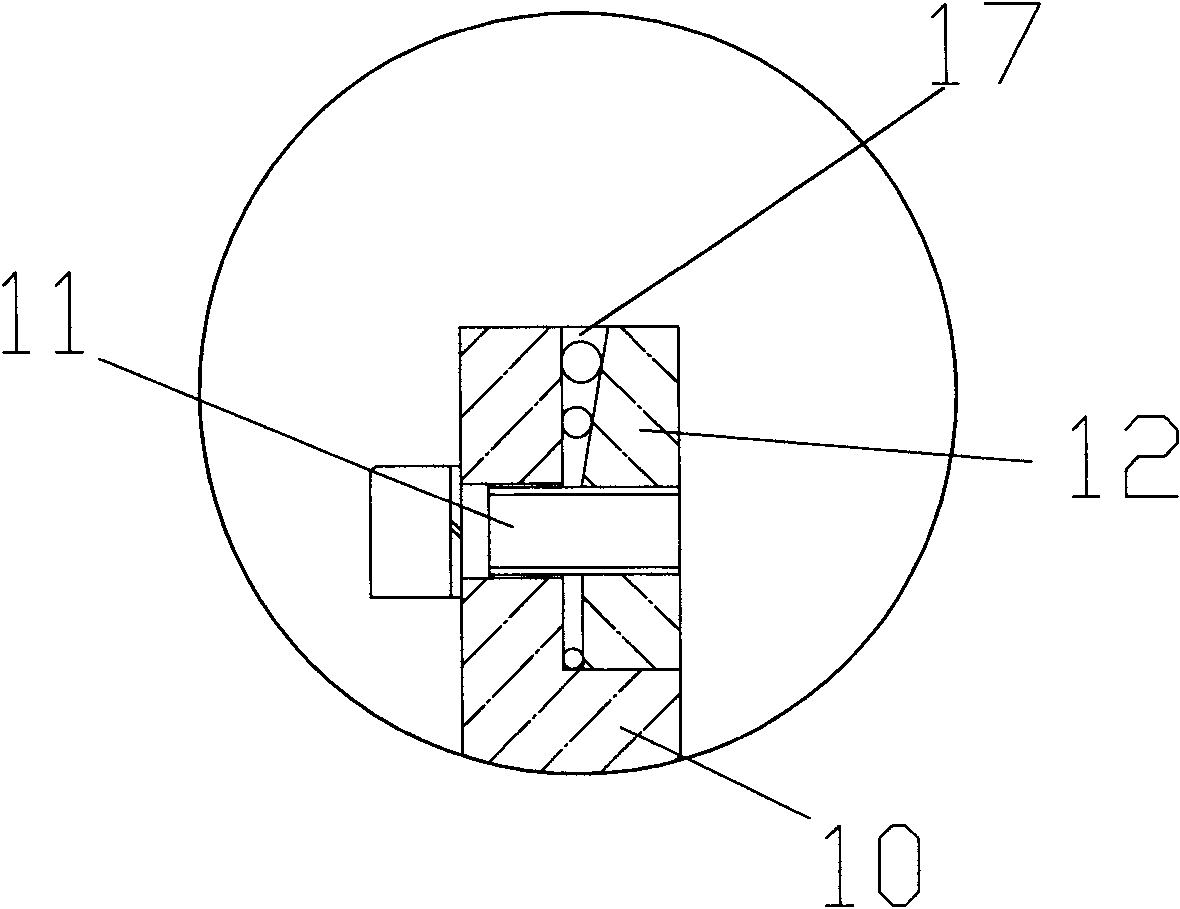

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view at I, as shown in the figure: the multi-strand spring CNC machine tool steel wire tension controller of the present embodiment includes a housing 1, a tension acquisition assembly and a tension control assembly, and the housing 1 is arranged in cooperation with its rotation in the circumferential direction Steel wire box 19, tension control assembly includes magnetic powder brake 3 and damping part, and damping part includes brake disk 10 and damping ring 12 that are connected in parallel in the axial direction, and brake disk 10 and housing 1 rotate in the circumferential direction, and damping ring 12 and An annular thread passing groove 17 is formed between the brake discs 10 along the circumferential direction, and the brake shaft of the magnetic powder brake 3 meshes with the brake disc 10 in the circumferential direction; in this embodiment, the brake shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com