Process and apparatus for the production of hydroxytyrosol containing extract from olives and solids containing residues of olive oil extraction

A technology of hydroxytyrosol and olive oil, applied in chemical instruments and methods, preparation of organic compounds, pressure vessels used in chemical processes, etc., can solve problems such as increased degradation of hydroxytyrosol, high oleuropein content, and harsh conditions , to achieve a good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

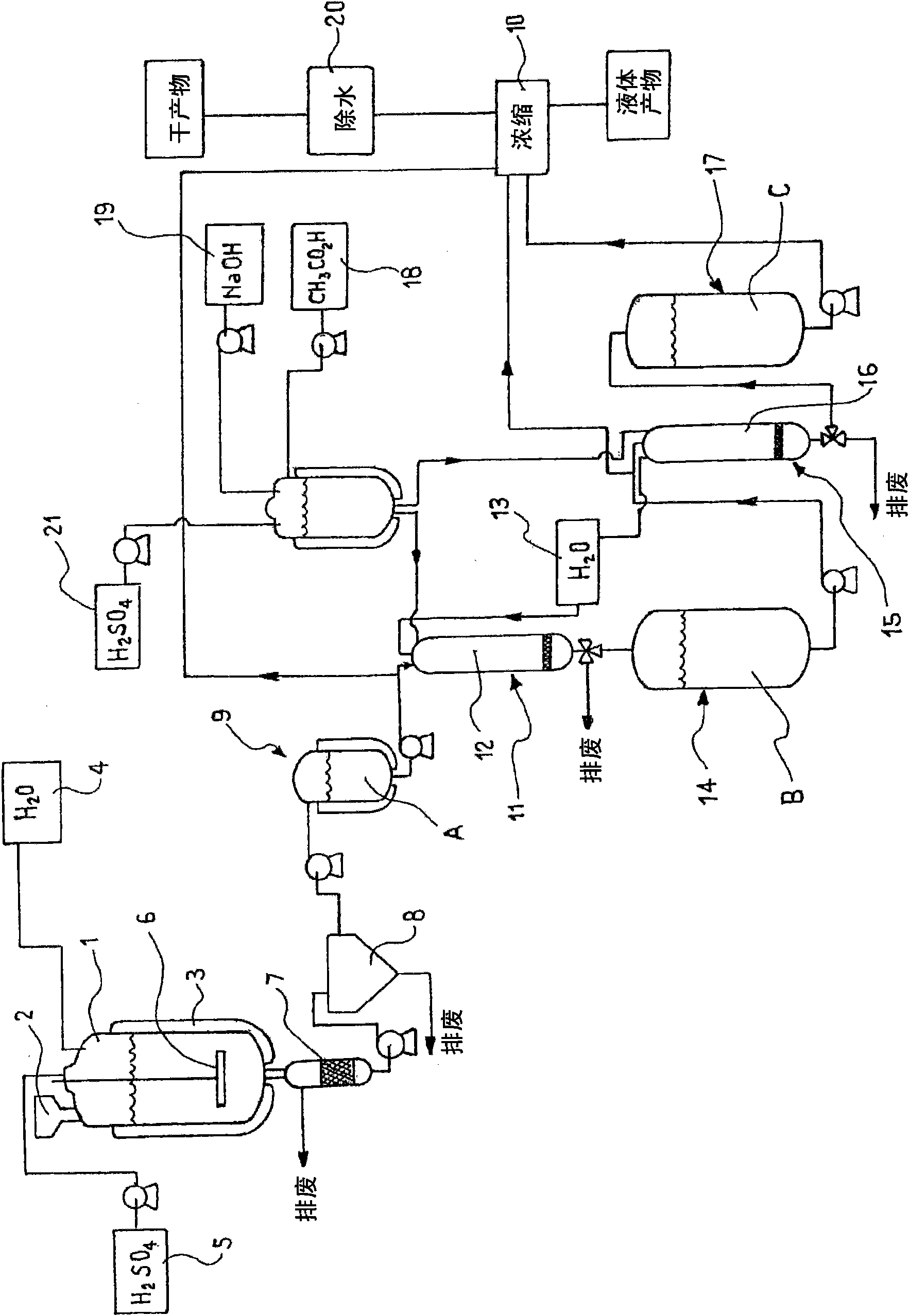

Method used

Image

Examples

Embodiment 1

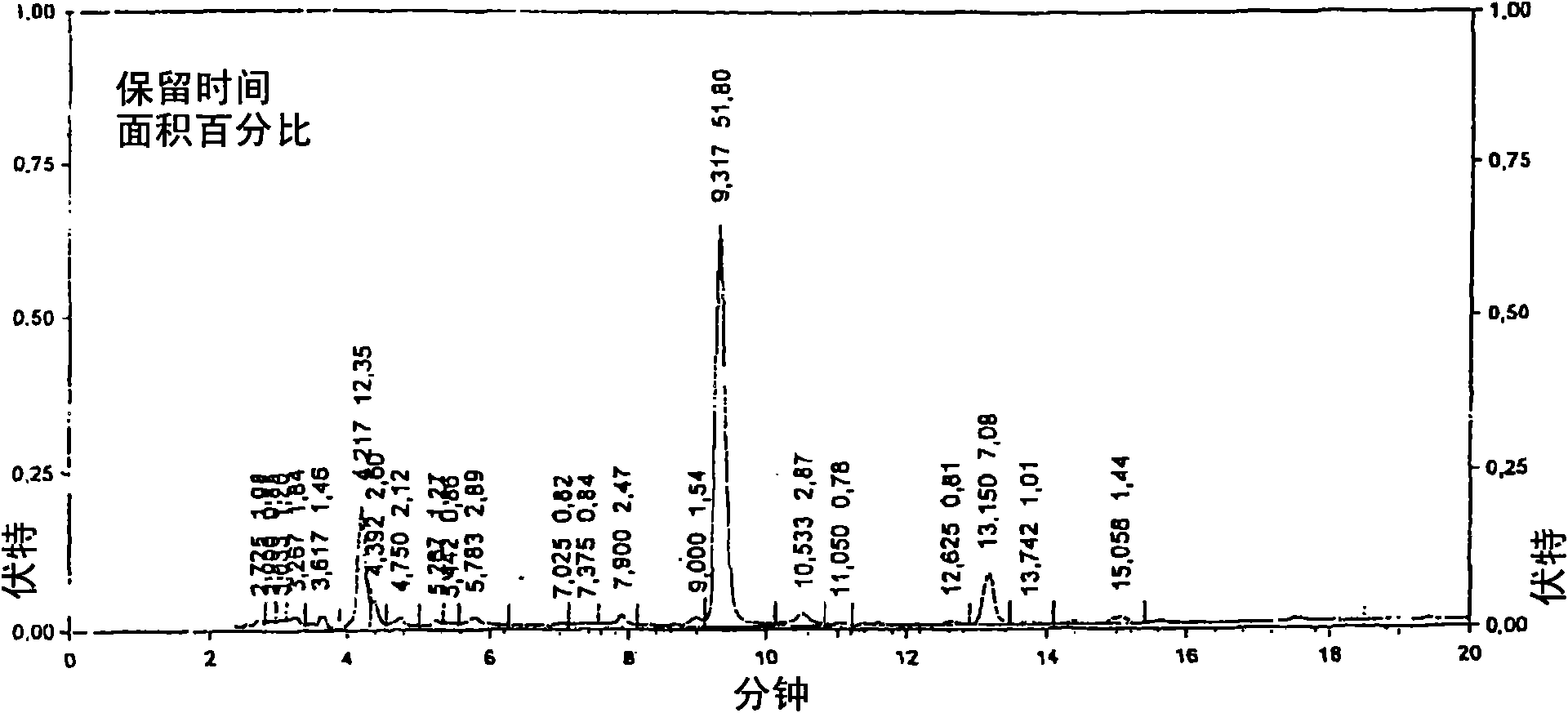

[0072] Extraction of hydroxytyrosol from olive waste (orujillo), purification of the aqueous phase

[0073] A 250 g sample of the dried olive waste oruillo was mixed with 838 ml demineralized water and 16.7 g sulfuric acid (98%). The resulting mixture was kept in an autoclave at 121°C for 30 minutes. The aqueous phase was then separated from the solid residue by filtration on a filter. The solid phase remaining on the filter was washed with 310 ml of demineralized water, and the water from this washing operation was collected together with the previously recovered aqueous phase. About 860 ml of the aqueous phase was then purified by centrifugation to remove solid particulates that passed through the filter. After removal of the solids, 835 ml of crude water extract were obtained containing 1.41 g of hydroxytyrosol with HPLC purity of 47.5%.

Embodiment 2

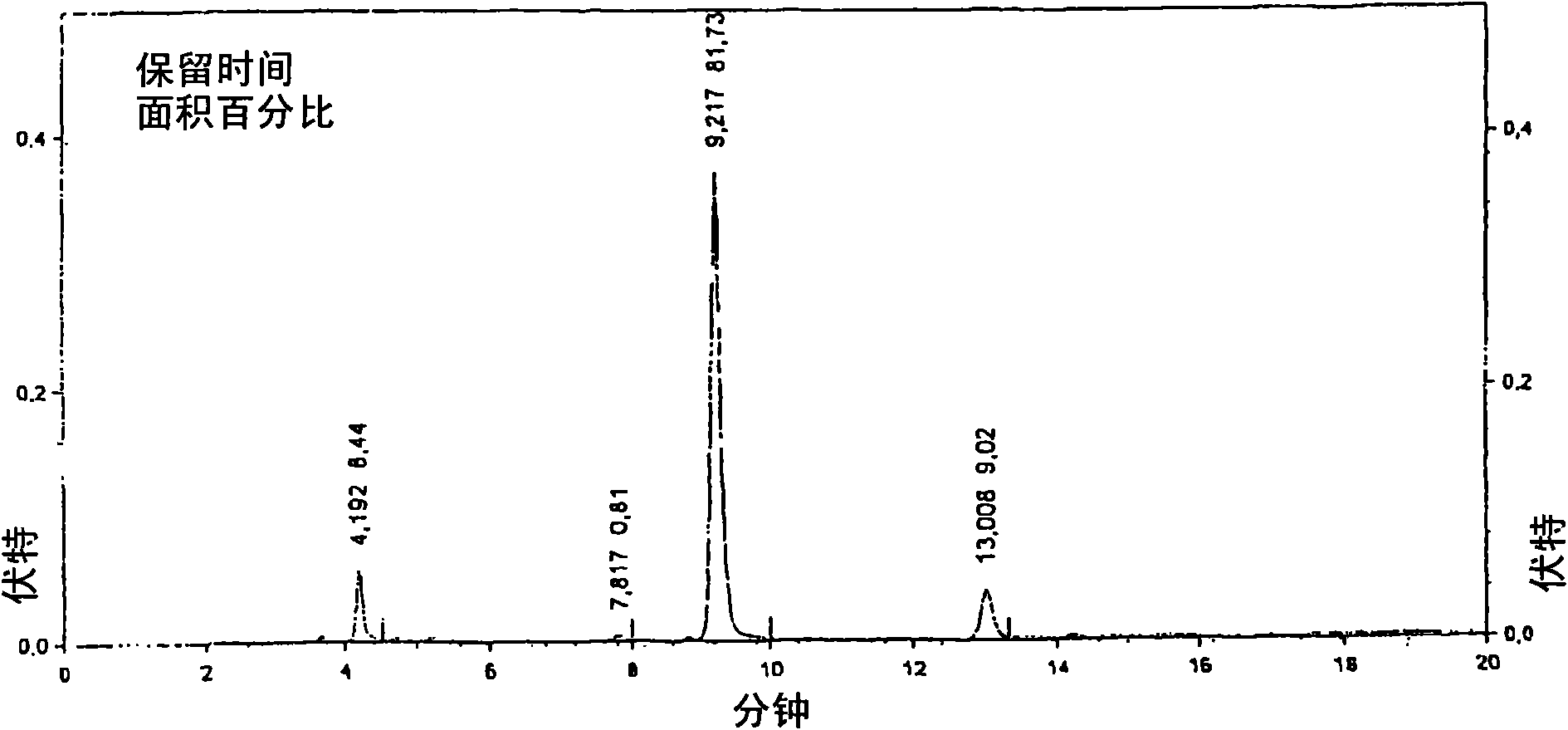

[0075] Ion Exchange Hydroxytyrosol Purification

[0076] 835 ml of a sample of the crude aqueous extract obtained according to Example 1, containing 1.41 g of hydroxytyrosol, were loaded onto a column containing an anionic ion exchange resin previously activated by acetate cycling. For example, Diaion WA10 can be used. The liquid phase recovered at the end of the column did not contain any hydroxytyrosol, and instead the column was continuously eluted with demineralized water until at least 90% of the initial charge of hydroxytyrosol was recovered. The eluate phase contained approximately 1.27 g of hydroxytyrosol with an HPLC purity of approximately 80.85%.

Embodiment 3

[0078] Ion exchange and adsorption of hydroxytyrosol purification

[0079] 835 ml of a sample of the crude aqueous extract obtained according to Example 1, containing 1.41 g of hydroxytyrosol, were loaded onto a column containing an anionic ion exchange resin previously activated by acetate cycling. For example, IRA-67 can be used. The liquid phase recovered at the end of the column did not contain any hydroxytyrosol, and instead the column was continuously eluted with demineralized water until at least 90% of the initial charge of hydroxytyrosol was recovered.

[0080] The eluate phase from the first column is loaded onto a column containing an adsorbent resin. For example, resin XAD-1180 can be used. The liquid phase recovered at the end of the column did not contain any hydroxytyrosol. The hydroxytyrosol is then eluted from the resin with demineralized water until at least 90% of the initial charge of hydroxytyrosol is recovered. The eluate phase contained approximate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com