Super-light leisure sports fabric and production method thereof

A fabric and sports technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of harsh washing conditions, poor light resistance, difficult to sell, etc., to achieve good drape, easy to exercise, and reduce the effect of restraint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

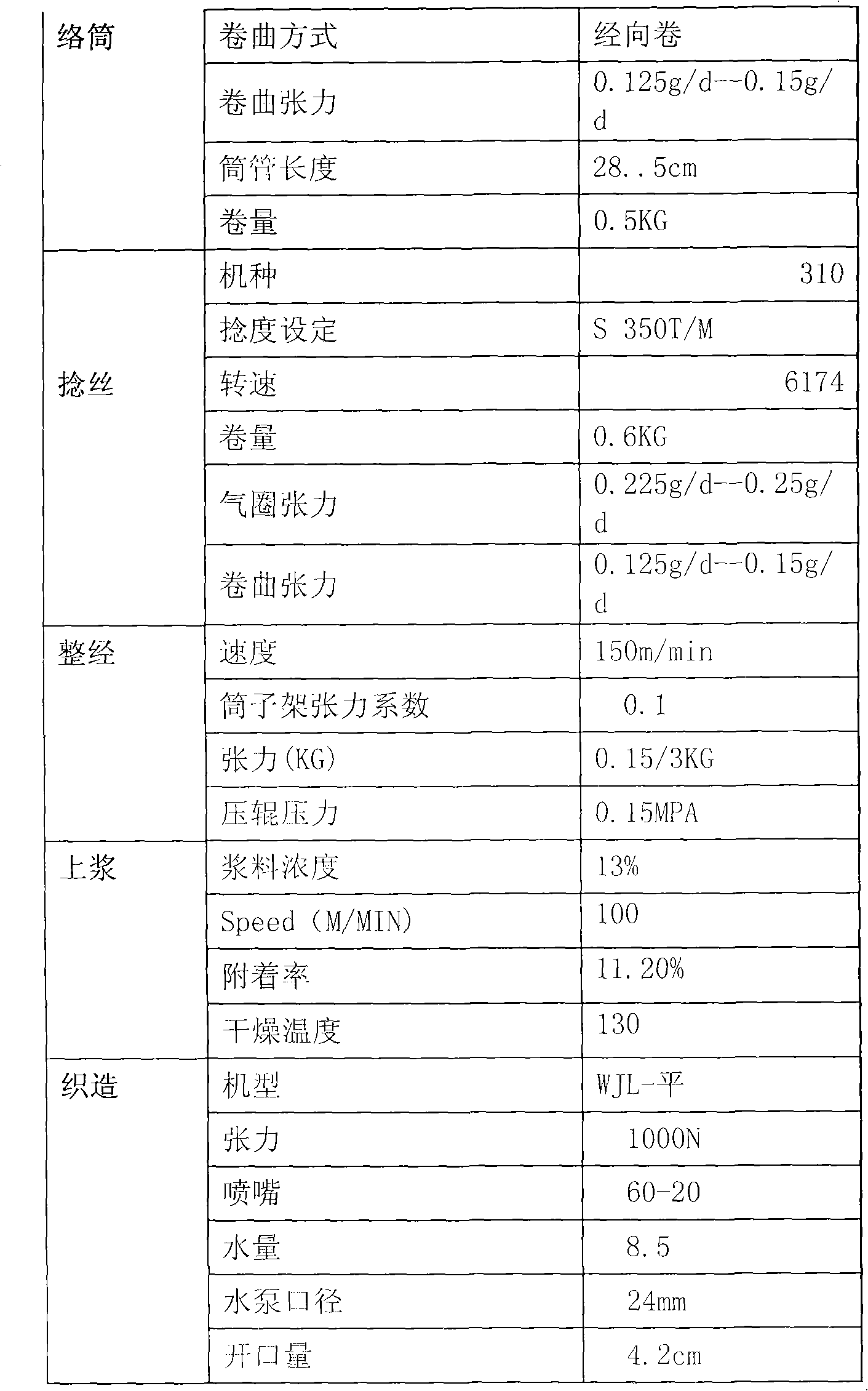

[0017] An ultra-lightweight casual sports fabric with a plain weave. The warp and weft yarns are made of 20D-24-DTY. The composition is ordinary polyester, and the single-filament fineness is 0.1 denier. / M, after warping and sizing, weaving on a plain weave loom. Weaving tension: 1000N, rotation speed 450RPM, weft density wheel: 150T, gray fabric warp and weft density: 167 threads / inch*155 threads / inch.

[0018] The gray cloth above goes through scouring→presetting→dyeing→drying→functional finishing (including drying resin)→heat setting→calendering→coating→heat setting. Finally, a finished product is produced. Finished warp and weft density: 180 threads / inch*162 threads / inch. Key process parameters:

[0019]

[0020] Scouring: temperature 95 degrees, speed: 60m / min, dwell time: 15~20 seconds.

[0021] Pre-molding: temperature 180 degrees, speed: 50m / min, set width: 155cm, finished width: 154cm,

[0022] Wind speed: 30HZ, the falling cloth is curled.

[0023] Dyeing m...

Embodiment 2

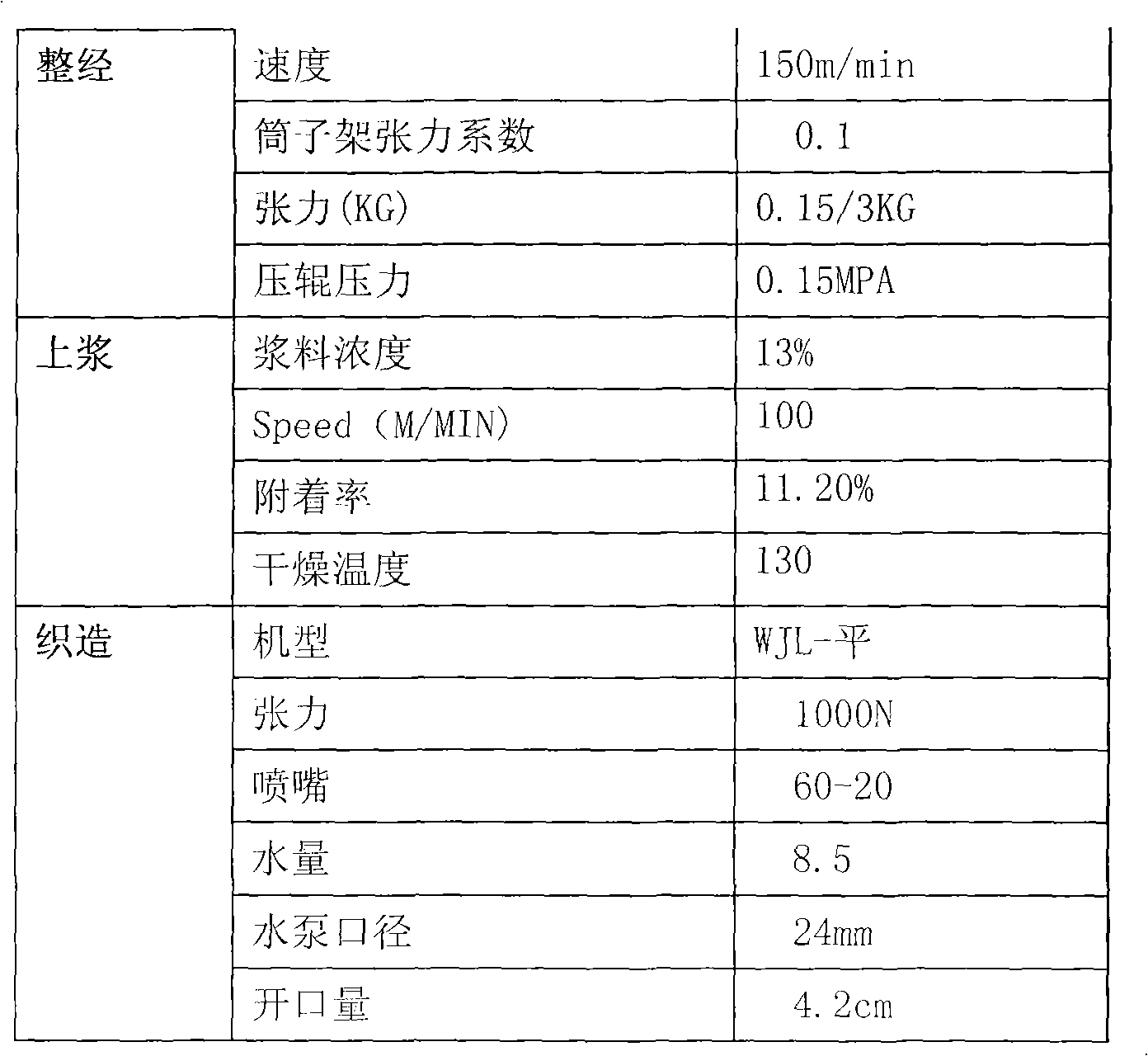

[0030] An ultra-light casual sports fabric, the weave adopts variable plain weave, the warp and weft yarns are 20D-7-FDY, the composition is nylon 6, and the monofilament fineness is 2 denier. Weaving on the machine. Weaving tension: 1000N, rotation speed 450RPM, weft density wheel: 150T, gray fabric warp and weft density: 191 / inch*155 / inch

[0031] The above-mentioned gray cloth goes through refining→presetting→dyeing→drying→heat setting→filming→post-waterproofing→heat setting→cold rolling. Made products. Finished warp and weft density: 210 threads / inch*172 threads / inch.

[0032] Key Process Parameters

[0033]

[0034] Refining temperature 95 degrees, speed: 60m / min, residence time: 15~20 seconds.

[0035] Pre-forming temperature: 180 degrees, speed: 30m / min, set width: 160cm, finished width: 160cm, wind speed: 30HZ, the cloth falls by curling.

[0036] Dyeing maximum temperature: 100°C*30min, heating rate: 1.5°C / min, cooling rate: 2.0°C / min, liquor ratio: 1:20

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com