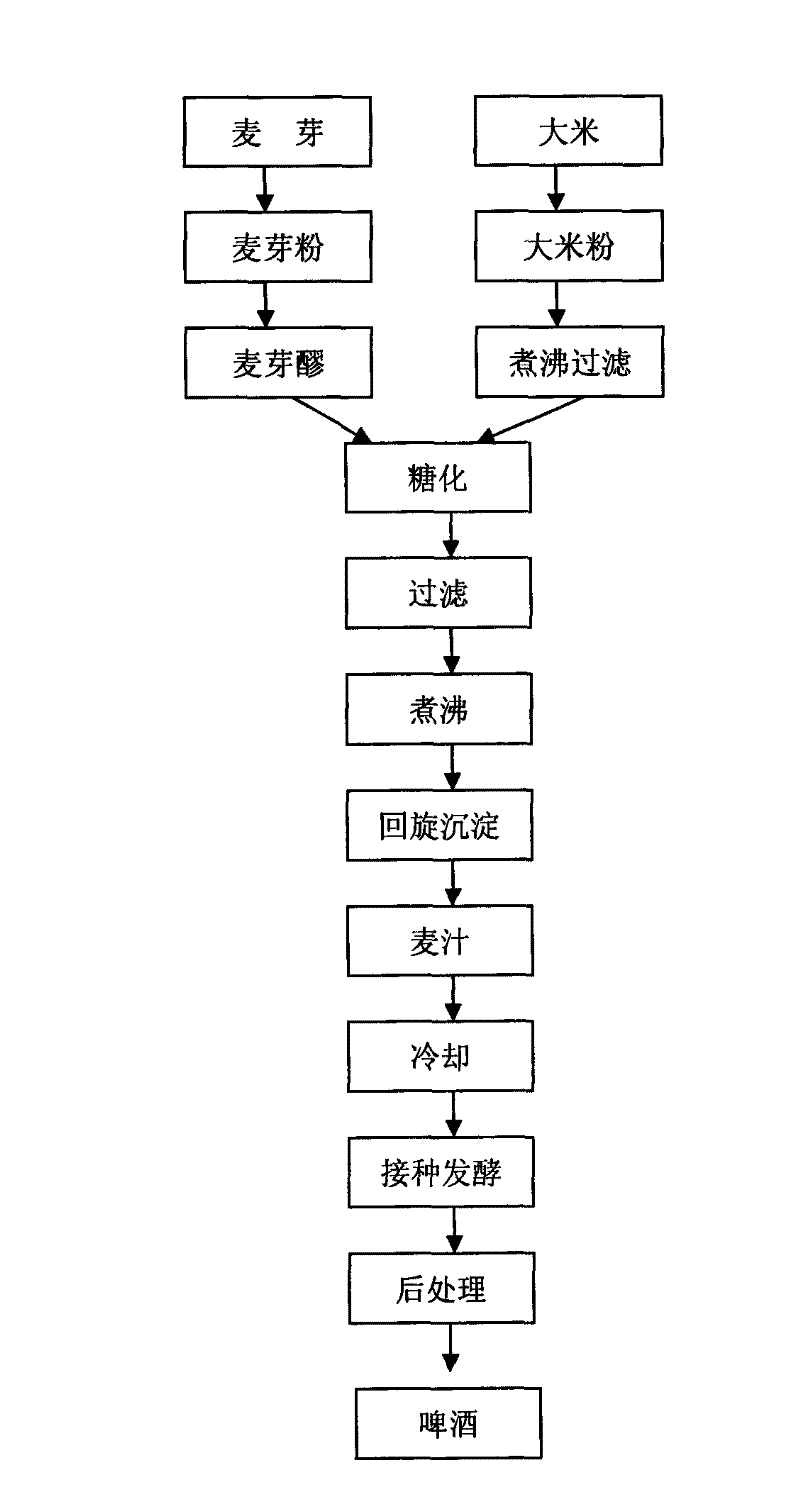

Preparation method for maize starch syrup used for beer fermentation

A corn starch and beer fermentation technology, which is applied in the directions of microorganism-based methods, beer brewing, wort preparation, etc., can solve the problems of affecting beer quality, insufficient α-amino nitrogen, unreasonable sugar composition of corn starch syrup, and the like, Achieve the effect of reducing beer production cost, sufficient α-amino nitrogen content, and shortening saccharification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

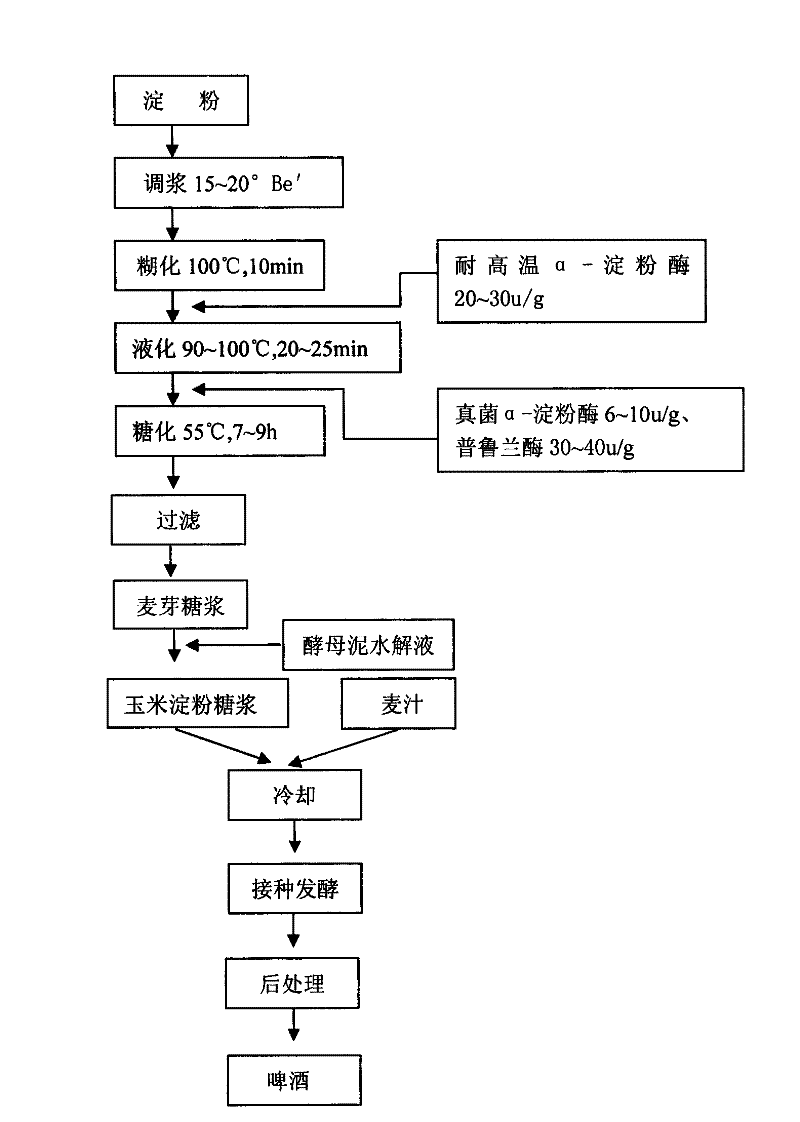

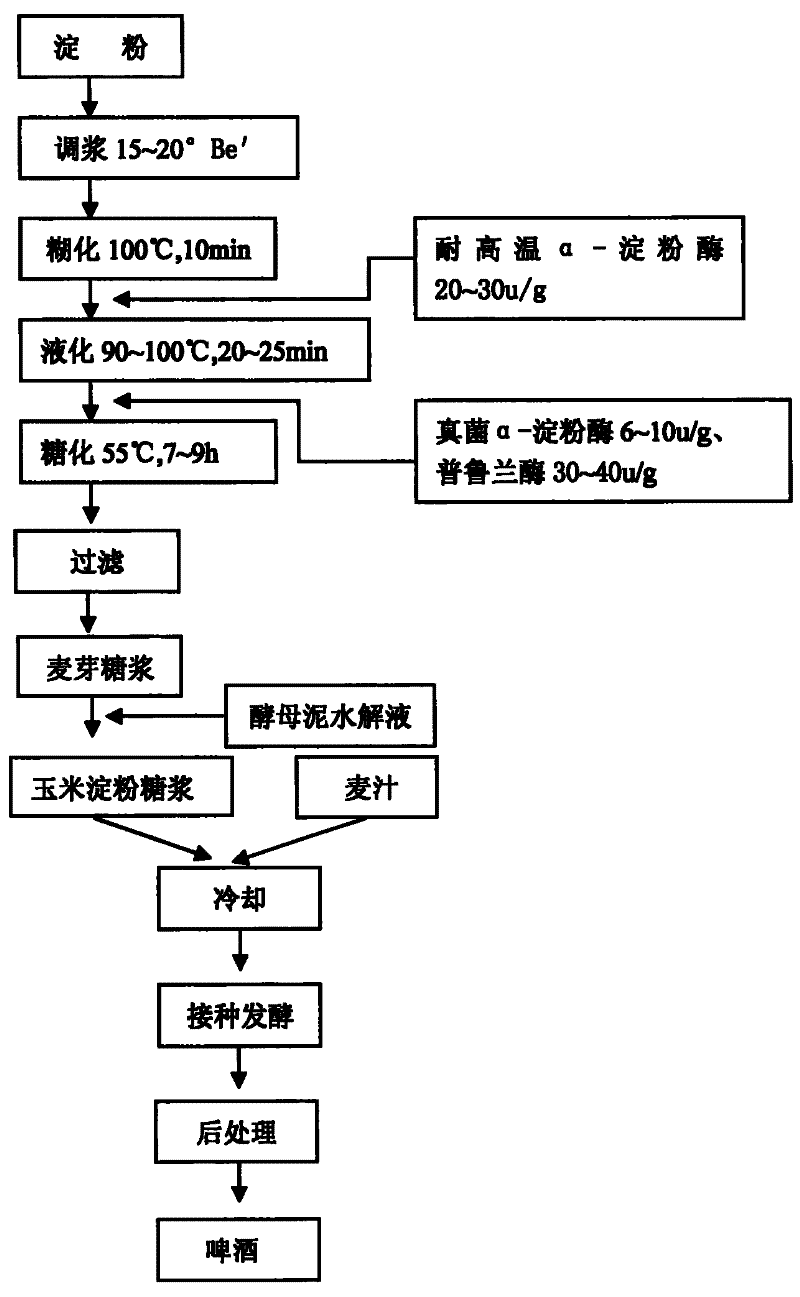

[0018] Embodiment 1: Preparation of cornstarch syrup and syrup for beer production, see the specific process figure 2 .

[0019] 1. Preparation of Corn Starch Syrup

[0020] a. Preparation of maltose syrup: Weigh cornstarch and put it into the mixing tank, add water into the tank, stir until the concentration is 17°Be', gelatinize at 100°C for 10min, and then add corn starch in an amount of dry basis corn The amount of starch is based on the high temperature resistant α-amylase 25u / g, at 100°C, after liquefaction for 20 minutes, then add fungal α-amylase 6u / g based on the amount of corn starch on a dry basis and common Lulanase 35u / g, pH value 5.5, temperature 55°C, saccharification for 9 hours, filter paper pressure filtration, detected maltose syrup DE value 50%, maltose concentration 57% maltose syrup, set aside.

[0021] b. Preparation of beer yeast slime hydrolyzate: first pretreat the fresh yeast slime, wash with three times distilled water, then pass through an 80-me...

Embodiment 2

[0026] Embodiment 2: preparation cornstarch syrup and syrup are used for beer production

[0027] 1. Preparation of Corn Starch Syrup

[0028]a. Preparation of maltose syrup: Weigh cornstarch and put it into a mixing tank, add water into the tank, stir until the concentration is 15°Be', gelatinize in a boiling water bath at 100°C for 10min, and then add the amount to dry The amount of base corn starch is 30u / g of high-temperature-resistant α-amylase based on the calculation basis. After liquefying at 90°C for 25 minutes, add 10u / g of fungal α-amylase based on the dry basis of corn starch and pullulanase 40u / g, control the pH value to 5.5, the temperature is 55°C and the saccharification time is 7h, and then the filter paper is pressure-filtered to obtain a maltose syrup with a DE value of 45% and a maltose concentration of 55%, which is set aside.

[0029] b. Preparation of beer yeast slime hydrolyzate: first pretreat the fresh yeast slime, wash with three times distilled wat...

Embodiment 3

[0034] Embodiment 3: Preparation of cornstarch syrup and syrup for beer production

[0035] 1. Preparation of Corn Starch Syrup

[0036] a. Preparation of maltose syrup: Weigh cornstarch and put it into a slurry mixing tank, add water into the tank, stir until the concentration is 20°Be', gelatinize in a boiling water bath at a temperature of 100°C for 10min, add the amount to dryness The amount of base corn starch is 30u / g of high-temperature-resistant α-amylase as the basis for calculation. After liquefying at 100°C for 25 minutes, add 8u / g fungal α-amylase and 40u / g pullulanase, and fungal α-amylase The amount of enzyme and pullulanase added is calculated based on the amount of corn starch on a dry basis, the pH value is controlled at 5.5, the temperature is 55°C, saccharification is carried out for 8 hours, and the filter paper is filtered under pressure to obtain a DE value of 60% and a maltose concentration of 60%. % maltose syrup, set aside.

[0037] b. Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com