Method for manufacturing coke biomass fuel bricks

A technology of biomass fuel and manufacturing method, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low compression ratio, low calorific value, easy generation of flue gas, etc., and achieves improved compatibility, high density, and burning time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Raw material selection, proportioning and fermentation treatment

[0022] According to mass percentage, 50% of crushed corn stalks, 10% of rice straw, 10% of leaves, 10% of peanut shells, 10% of cow dung, 5% of horse manure and 5% of biomass tar are mixed as biomass raw materials. The crushing particle size is between 1-2mm. The pulverized raw materials are fermented in an environment with a humidity of 50% and a temperature of 30°C.

[0023] 2. Drying

[0024] The biomass raw material is dried, and the drying heat source comes from the combustible gas generated by preheating. The moisture content of dried biomass raw materials is controlled below 10%.

[0025] 3. Preheat

[0026] The dried biomass raw material is preheated at a temperature of 200-250° C. for 20 minutes to remove some volatile components, reduce the volume of the biomass raw material, and increase the cohesive degree.

[0027] 4. Collect combustible gas and tar

[0028] During the preheating pr...

PUM

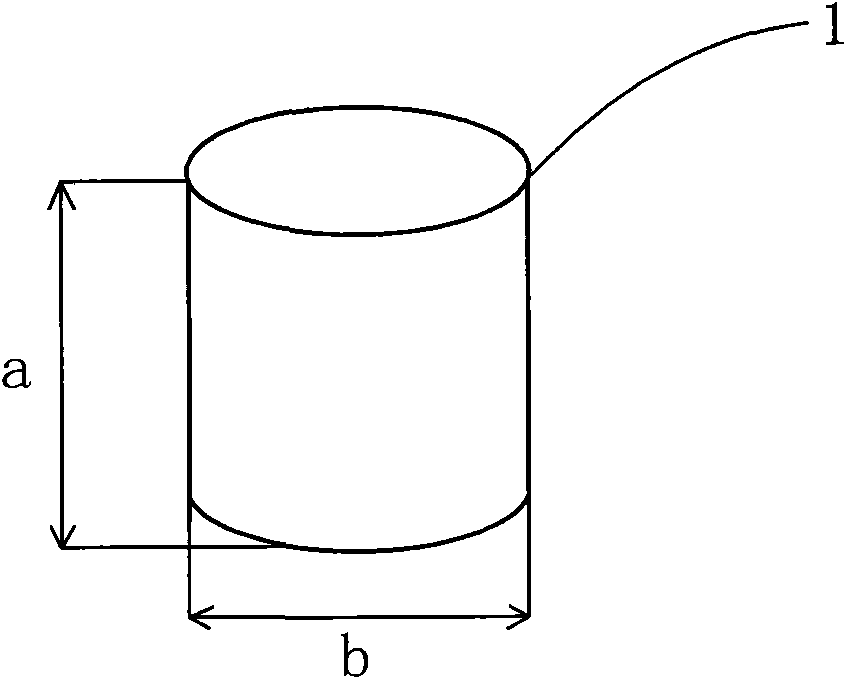

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com