Method for processing modified plant fibers of polyolefine wood-plastic composite

A wood-plastic composite material and plant fiber technology, which is applied to the processing field of modified plant fibers used for polyolefin wood-plastic composite materials, can solve the problem that the curing time reduces production efficiency, the wood powder modification is incomplete, and the wood powder is easy to mold. and other problems, to achieve the effect of improving the curing time and curing efficiency, the appearance of simulated wood, and the high content of plant fiber powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Preparation of dry oil

[0066] The formula for handling dry oil quality is as follows:

[0067] 100 parts linseed oil

[0068] Cobalt naphthenate 1 part

[0069] h 2 o 2 (30% concentration) 13 parts

[0070] The preparation process for dealing with drying oils is as follows:

[0071] Weigh linseed oil according to the formula and place it in an appropriate container, add cobalt naphthenate and H 2 o 2 , at room temperature, stir well to obtain dry oil.

[0072] 2. Preparation of modified plant fibers

[0073] The quality formula of plant fiber modification is as follows:

[0074] 100 parts of dry plant fiber powder (fir powder, 80 mesh)

[0075] Treat dry oil 4 parts

[0076] The preparation process of modified plant fiber is as follows:

[0077] Drying the plant fiber powder with an airflow cyclone dryer or other drying equipment until the water content is lower than 2%, to obtain a dry plant fiber powder;

[0078] Weigh the plant fiber powder accordin...

Embodiment 2~5

[0106] The preparation process of Examples 2-5 is the same as that of Example 1, except that the formula is different. The formulations of Examples 2-5 are shown in Table 2 to Table 4.

[0107] Table 2: Preparation formula for treating drying oils

[0108] Example

[0109] Table 3: Preparation formula of modified plant fiber powder

[0110] Example

[0111] 5

[0112] Table 4: Preparation formula of modified plastics

[0113] Example

[0114] Table 5: Preparation formula of wood-plastic composites

[0115]

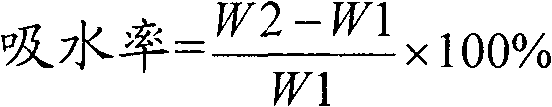

[0116] After testing, the wood-plastic composite materials prepared according to the above formula all have low water absorption (the absorption rate is lower than 3% after soaking in water for 2 months), and have good tensile strength, bending strength and impact strength.

Embodiment 6

[0118] The preparation steps of the modified plant fiber are the same as in Example 1, wherein the drying oil is processed in the following manner: take an appropriate amount of tung oil, drier or 30% H 2 o 2 Stir evenly according to the formula (mass ratio), in which tung oil + H 2 o 2 (100:13), tung oil + drier (100:2), tung oil + drier + H 2 o 2 (100:2:13) these three drying oils, wherein the drier is cobalt naphthenate. After discharging, it is placed under the following conditions for curing, and the curing results are as shown in Table 6:

[0119] Table 6: Treatment methods for drying oils

[0120]

[0121] It can be seen from the above chart that increasing the temperature, using ultraviolet photocatalysis and adding an appropriate amount of drier can shorten the curing time of the drying oil. The drier and ultraviolet rays promote the formation of free radicals, and adding an appropriate amount of hydrogen peroxide increases the internal dryness. The contact r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com