Method for reducing nitrogen loss during composting process

A technology of composting and mixed composting, applied in the direction of microbial-based methods, preparation of organic fertilizers, biochemical equipment and methods, etc., can solve the problems of not being able to meet various needs, multi-equipment and investment, and not easy to realize, and achieve effective Facilitate absorption, improve quality, and reduce nitrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

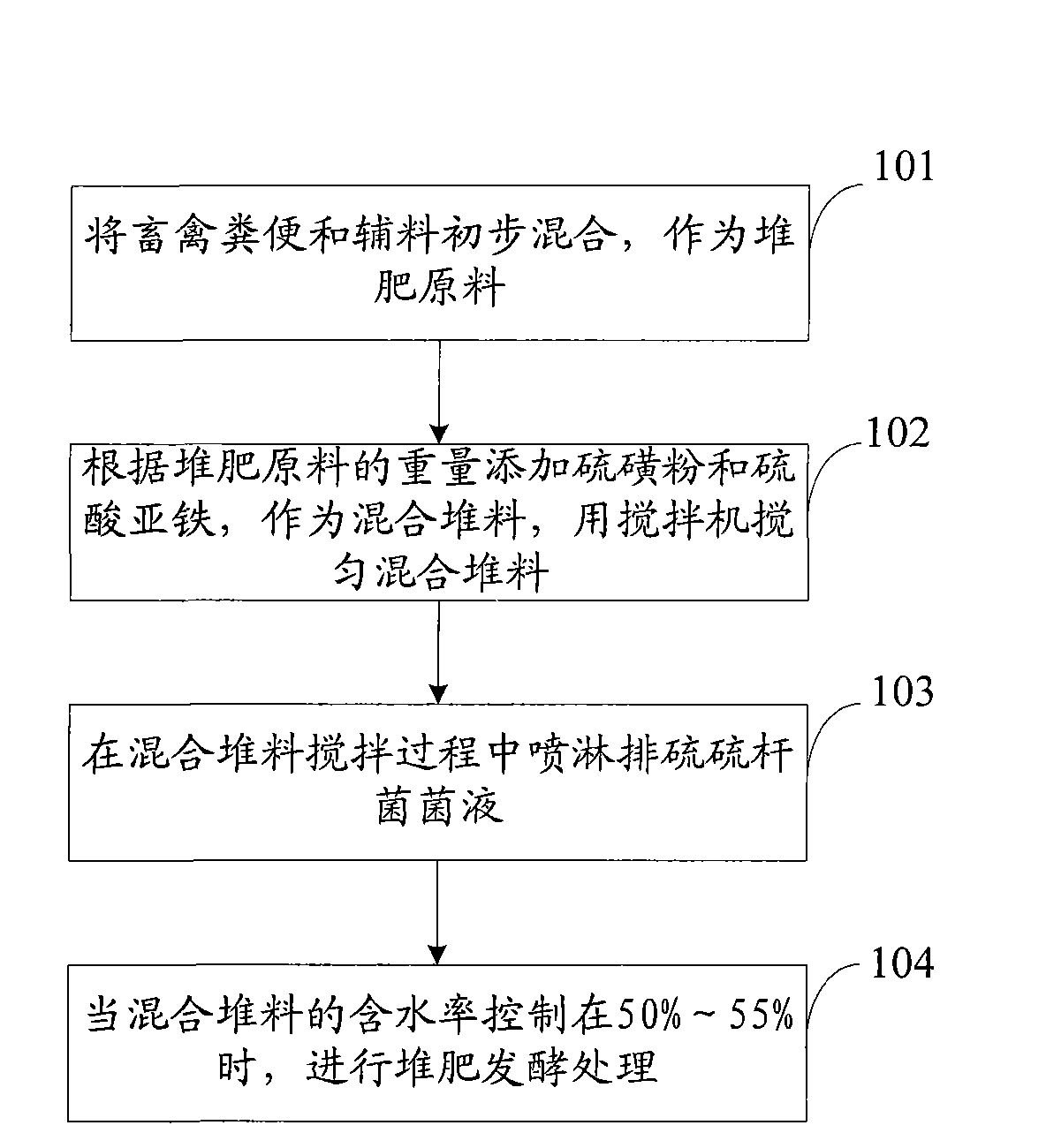

[0035] see figure 1 , the embodiment of the present invention provides a method for reducing nitrogen loss in the composting process, the specific steps are as follows:

[0036] Step 101: Preliminary mixing of livestock and poultry manure and other auxiliary materials as compost raw materials.

[0037] Step 102: Add sulfur powder and ferrous sulfate according to the weight of the composting raw materials as a mixed pile, and use a mixer to stir the mixed pile.

[0038] Among them, 0.25% to 0.50% of the weight of composting raw materials is added sulfur powder, and the sulfur powder is industrial sulfur powder of 100 mesh or more;

[0039] Wherein, 0.3% to 0.6% of ferrous sulfate is added based on the weight of the compost raw materials, and the ferrous sulfate is industrial green vitriol.

[0040] Step 103: Spraying the Thiobacillus thiaphrugans bacteria liquid during the stirring process of the mixed pile.

[0041] Wherein, 0.3% to 0.5% of the weight of the composting raw ...

Embodiment 2

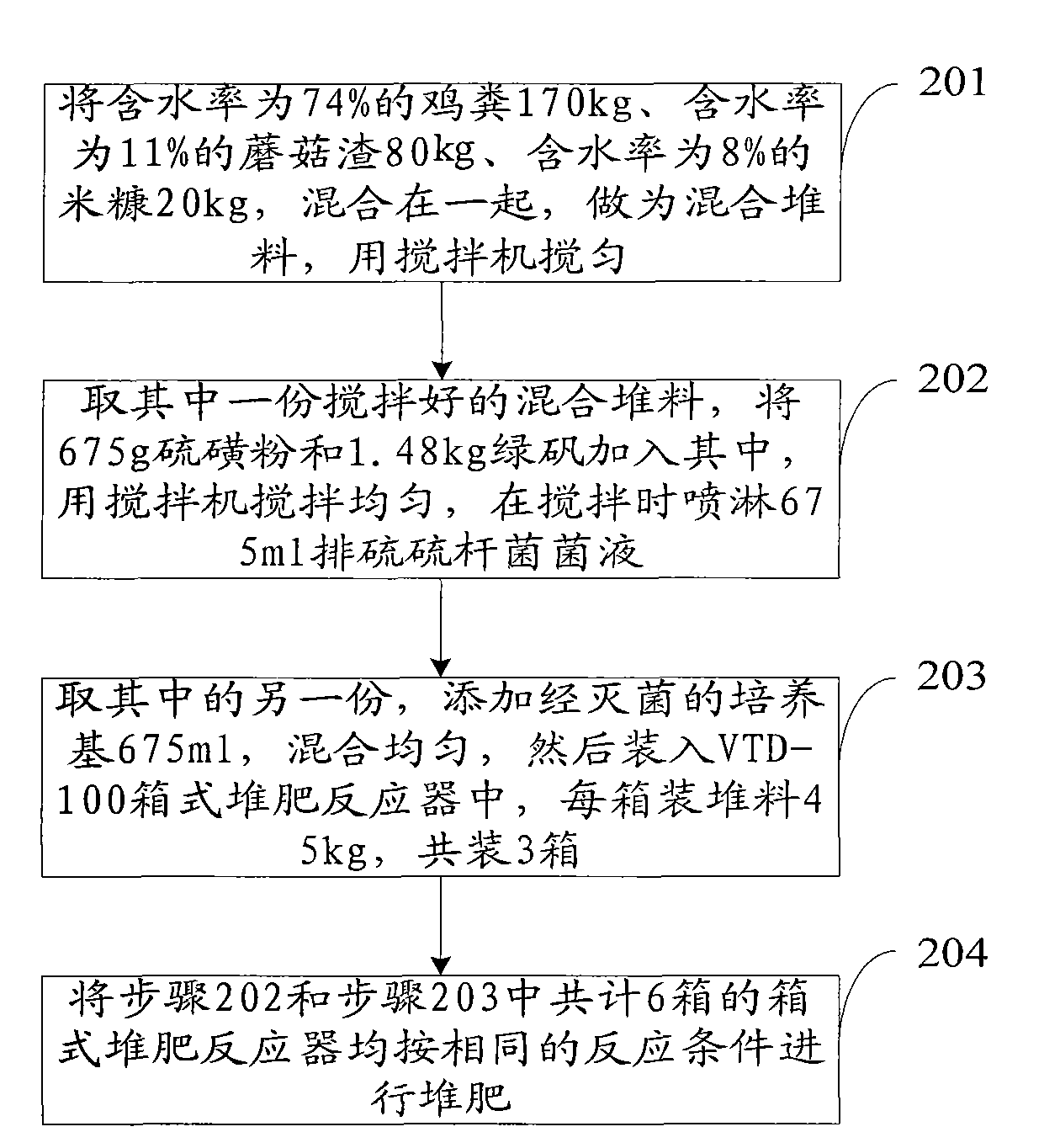

[0053] see figure 2 , the embodiment of the present invention provides a method for reducing nitrogen loss during composting. In this embodiment, chicken manure is used as an example for livestock and poultry manure, and mushroom dregs and rice bran are used as composting materials for auxiliary materials. The VTD-100 box-type composting reactor developed by the School of Resources and Environment, China Agricultural University was used to carry out the composting test. The specific implementation method is as follows:

[0054] Step 201: Mix 170 kg of chicken manure with a moisture content of 74%, 80 kg of mushroom dregs with a moisture content of 11%, and 20 kg of rice bran with a moisture content of 8%, as a mixed stock, and stir with a mixer.

[0055] Wherein, the moisture content of the mixed stock is about 50%, and the mixed stock that has been stirred is divided into 2 parts on average, that is, each part is 135kg.

[0056] Step 202: Take one part of the mixed stock th...

Embodiment 3

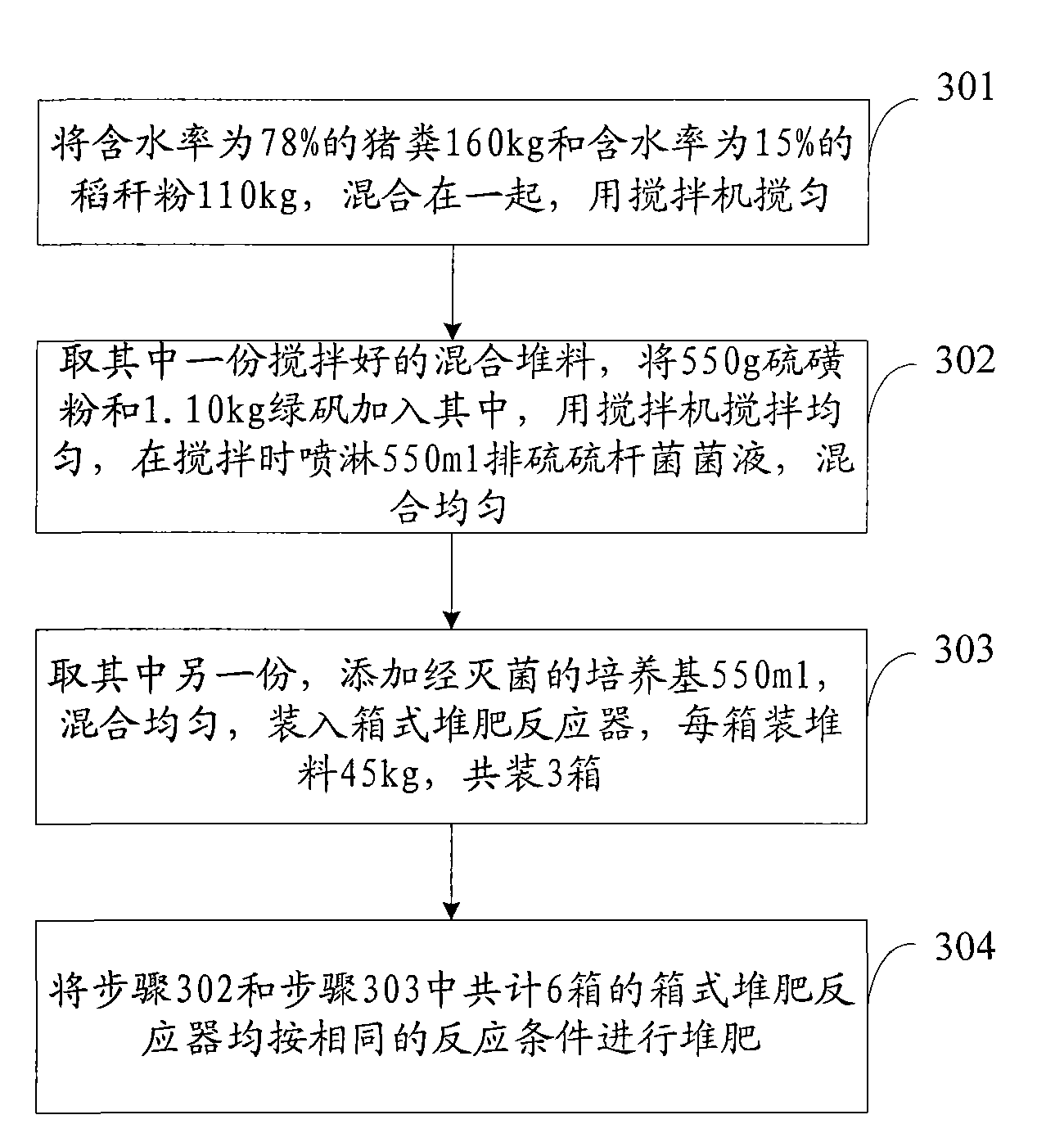

[0066] see image 3 , the embodiment of the present invention provides a method for reducing nitrogen loss in the composting process. In this embodiment, pig manure is used as an example for the livestock and poultry manure, and rice straw powder is used as the composting material for illustration. The VTD-100 box-type composting reactor developed by the School of Resources and Environment of China Agricultural University was used for composting experiments. The specific implementation methods are as follows:

[0067] Step 301: Mix 160 kg of pig manure with a moisture content of 78% and 110 kg of rice straw powder with a moisture content of 15% (wherein, the rice straw is crushed to 1 to 2 cm), and mix them together as a mixed stockpile, and stir them with a mixer uniform.

[0068] Wherein, the moisture content of the mixed stock is about 52%, and the mixed stock that has been stirred is divided into 2 parts on average, that is, each part is 135kg.

[0069] Step 302: Take on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com