Processing equipment and technique for waste acid and water

A sewage treatment device and sewage treatment technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. Problems such as poor operation flexibility, to achieve the effect of reducing the amount of treated water, facilitating low-cost treatment, and stably reaching the standard discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

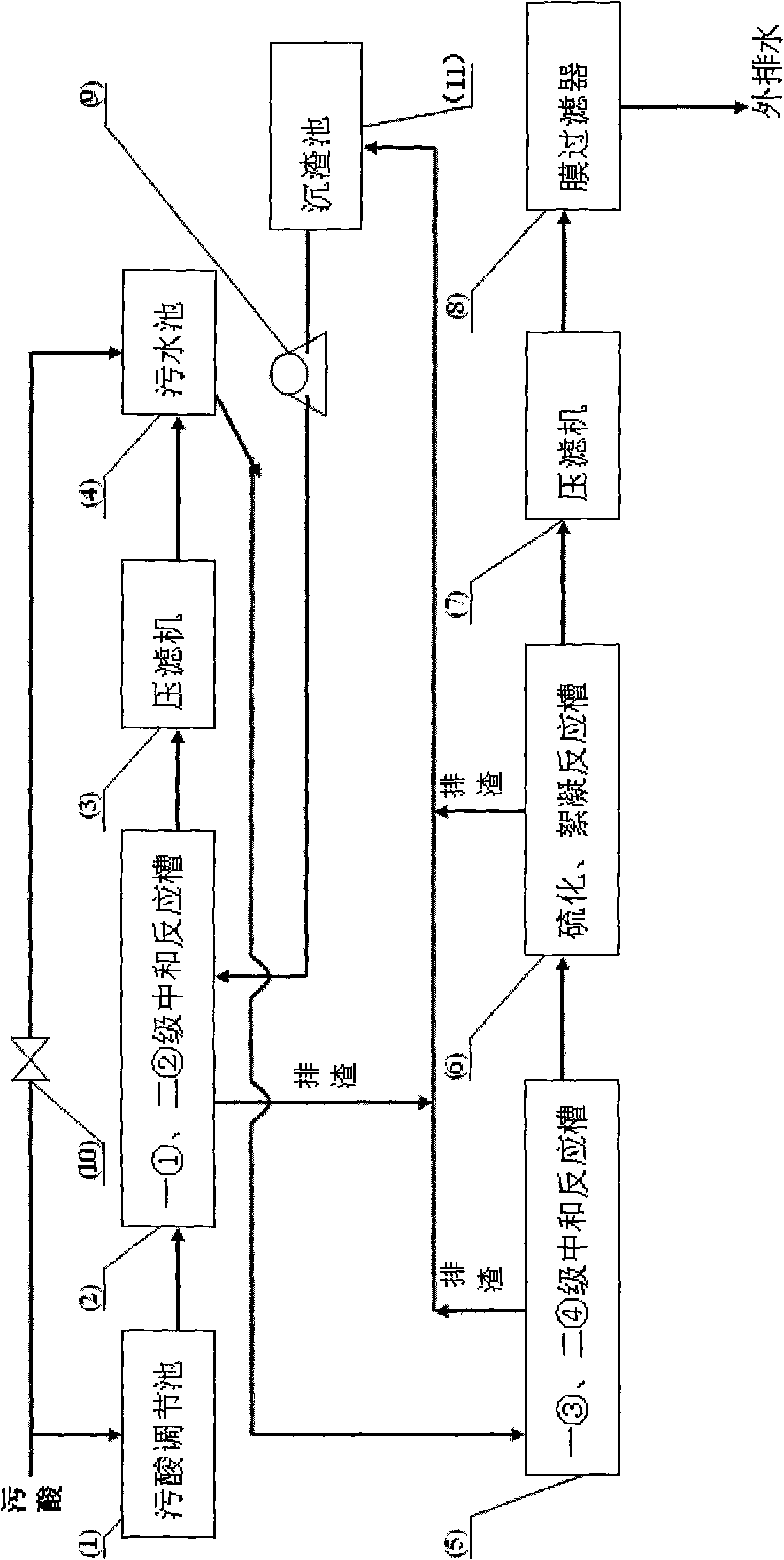

[0024] Such as figure 1 As shown, a dirty acid sewage treatment device includes a dirty acid regulating tank 1 connected with a dirty acid pipeline, and is characterized in that:

[0025] Sewage acid adjustment tank 1 is connected to the first stage of neutralization reaction tank 2 through pipelines and pumps. The first stage of neutralization reaction tank 2 includes the first stage of primary neutralization reaction tank ① and the first stage of secondary neutralization reaction Tank ②, the first-stage neutralization reaction tank ① of the first section and the second-stage neutralization reaction tank ② of the first section are connected by an overflow relationship, and the liquid overflows from the first-stage first-stage neutralization reaction tank ① to the first In the secondary neutralization reaction tank ② of the section, the secondary neutralization reaction tank ② of the first section is connected with the filter press 3, and the filter press 3 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com