Surface nanocrystallization method for titanium alloy material

A treatment method and nanotechnology, which is applied in the field of titanium alloy material surface nanotechnology, can solve the problems of rough hitting surface, uneven shot peening impact area, and the impact frequency and density of the hitting surface can only be statistical values, etc., to achieve Effects of increased refractive index, increased density, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

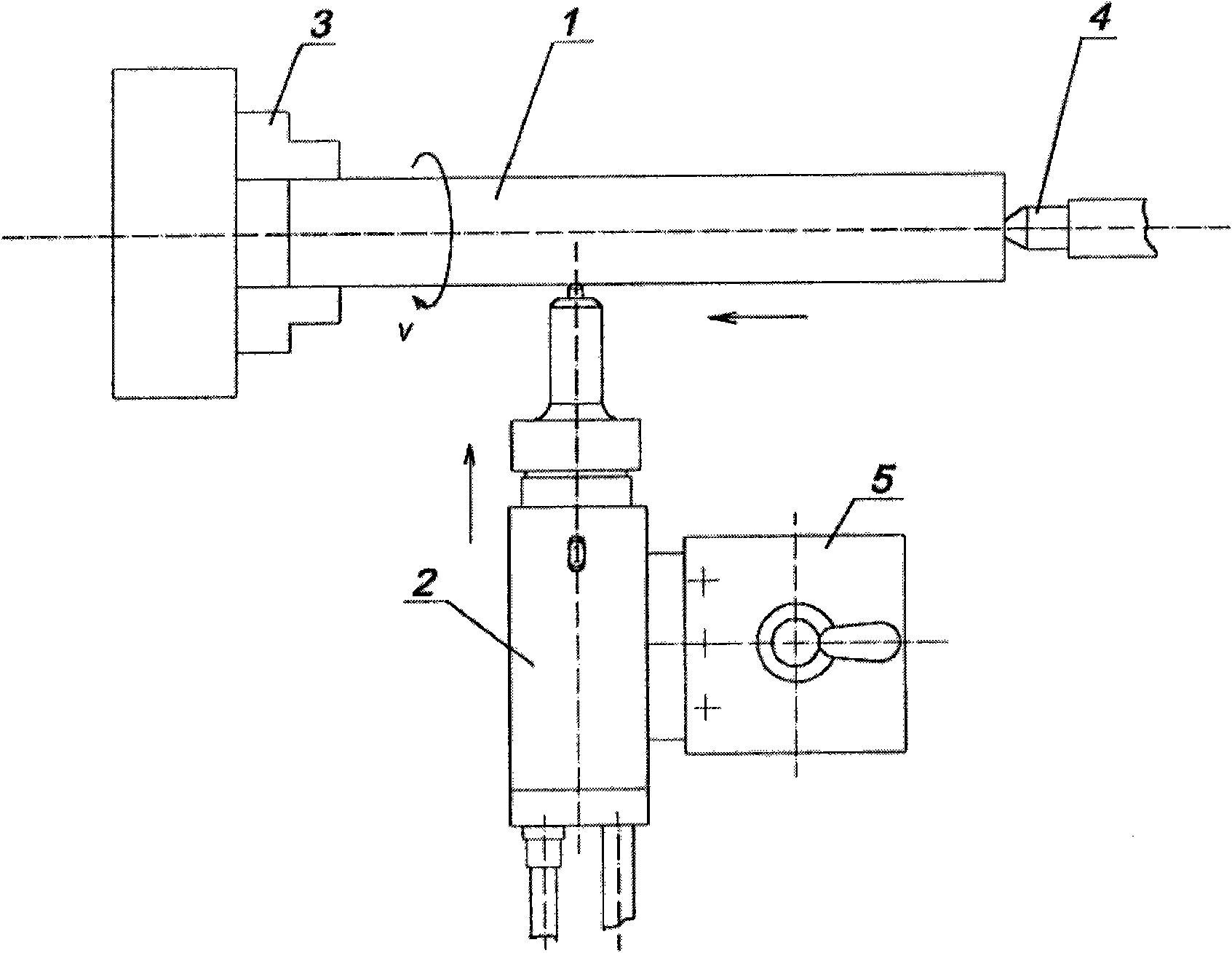

[0037] like figure 1 Shown is a schematic diagram of the surface treatment of the ultrasonic surface strengthening treatment method of the present invention. In the figure, 1 is the workpiece to be processed, 2 is the ultrasonic surface strengthening treatment device, 3 is the lathe chuck, 4 supports the lathe spindle, and 5 is the fixing frame of the ultrasonic surface strengthening treatment device. The workpiece 1 to be processed is clamped on the lathe by the lathe chuck 3 and the supporting lathe spindle 4; the ultrasonic surface strengthening treatment device 2 is fixed on the fixing frame 5 of the ultrasonic surface strengthening treatment device.

[0038] The ultrasonic surface strengthening treatment device includes an ultrasonic generating device, an ultrasonic working gun connected to it by a wire; the ultrasonic working gun includes: a punch, a waveguide, a sleeve, a shell, an ultrasonic transducer, a pressure spring, and a Compressed air conduit; the punch and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com