Frame car body structure of magnetic levitation type rail polling car

A car body structure and inspection car technology, which is applied to railway car bodies, railway car body parts, electric vehicles, etc., can solve the problems of not meeting the structural requirements of track inspection cars, the inability to integrate inspection cars, and the inability to realize equipment interlayers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

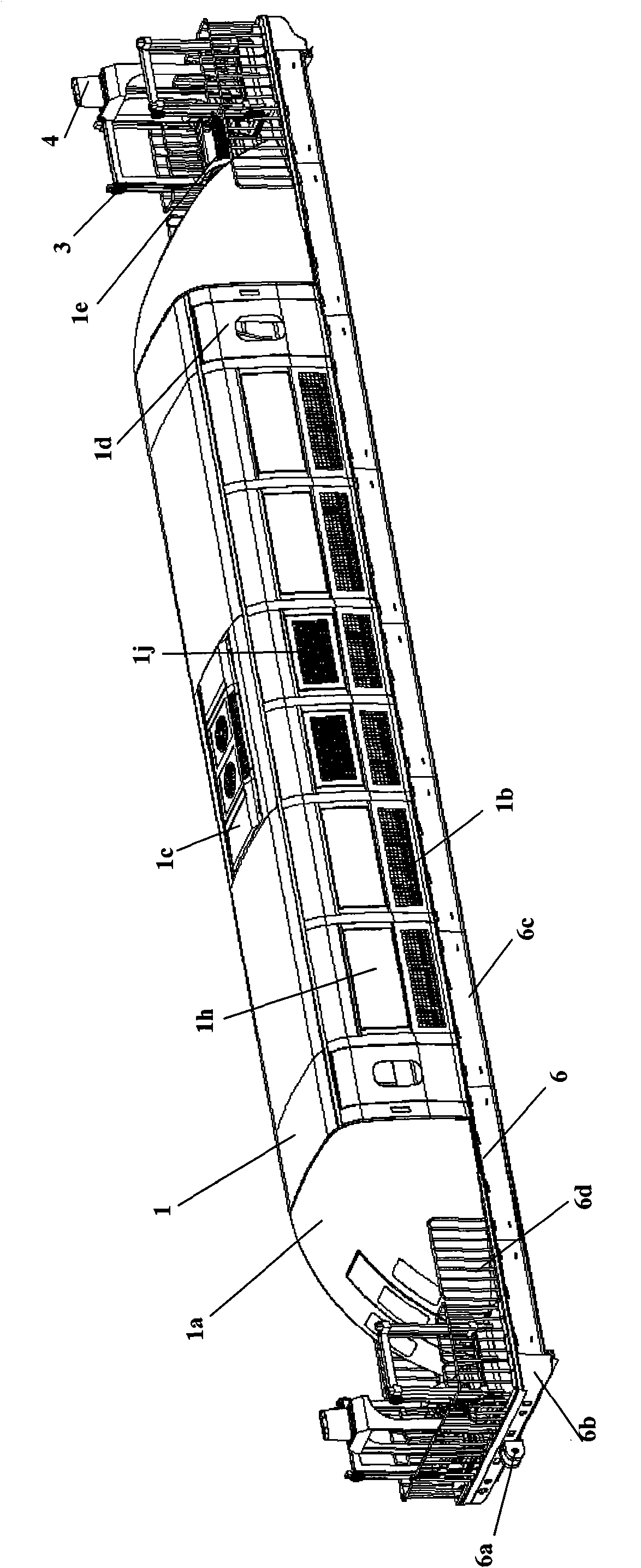

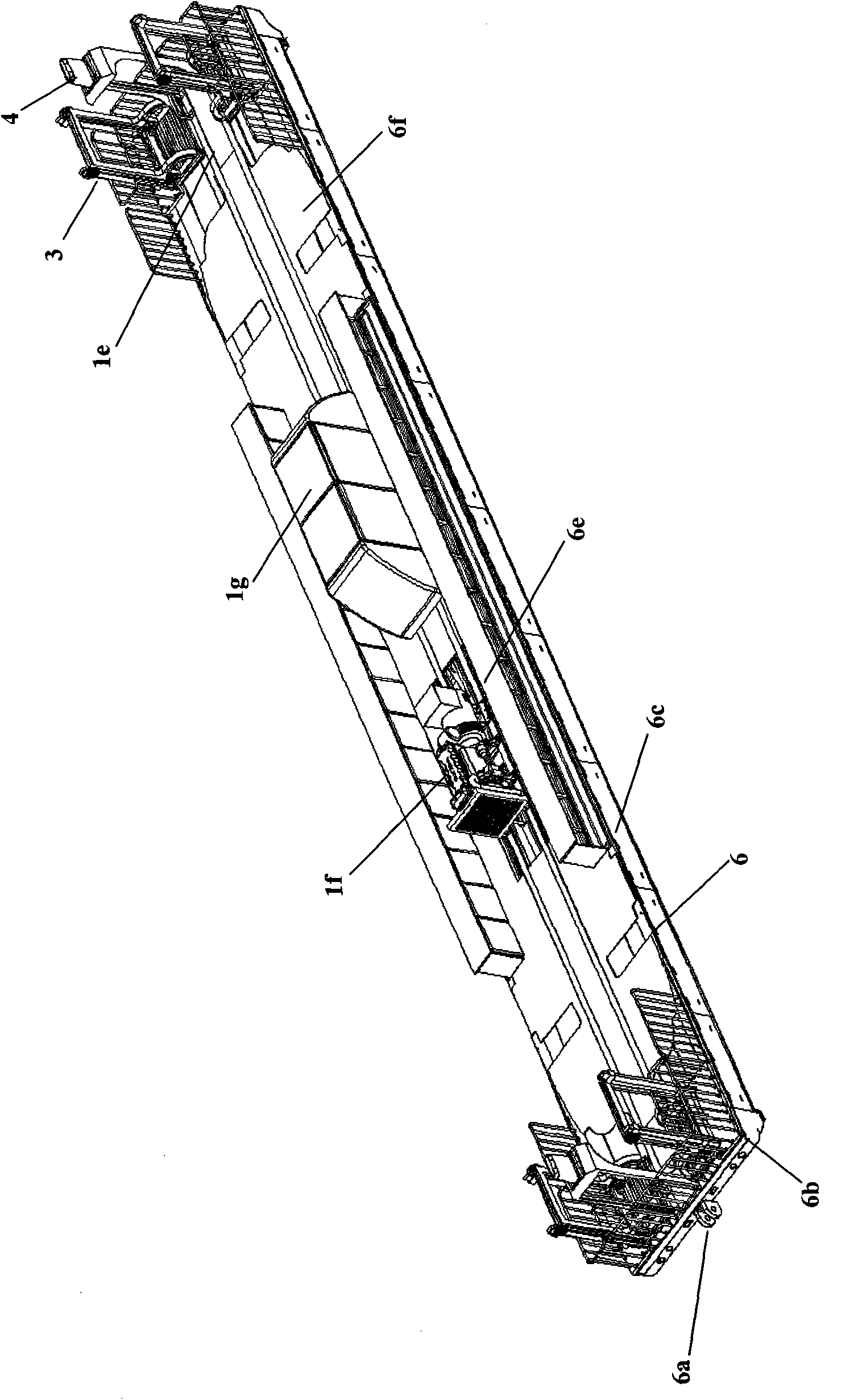

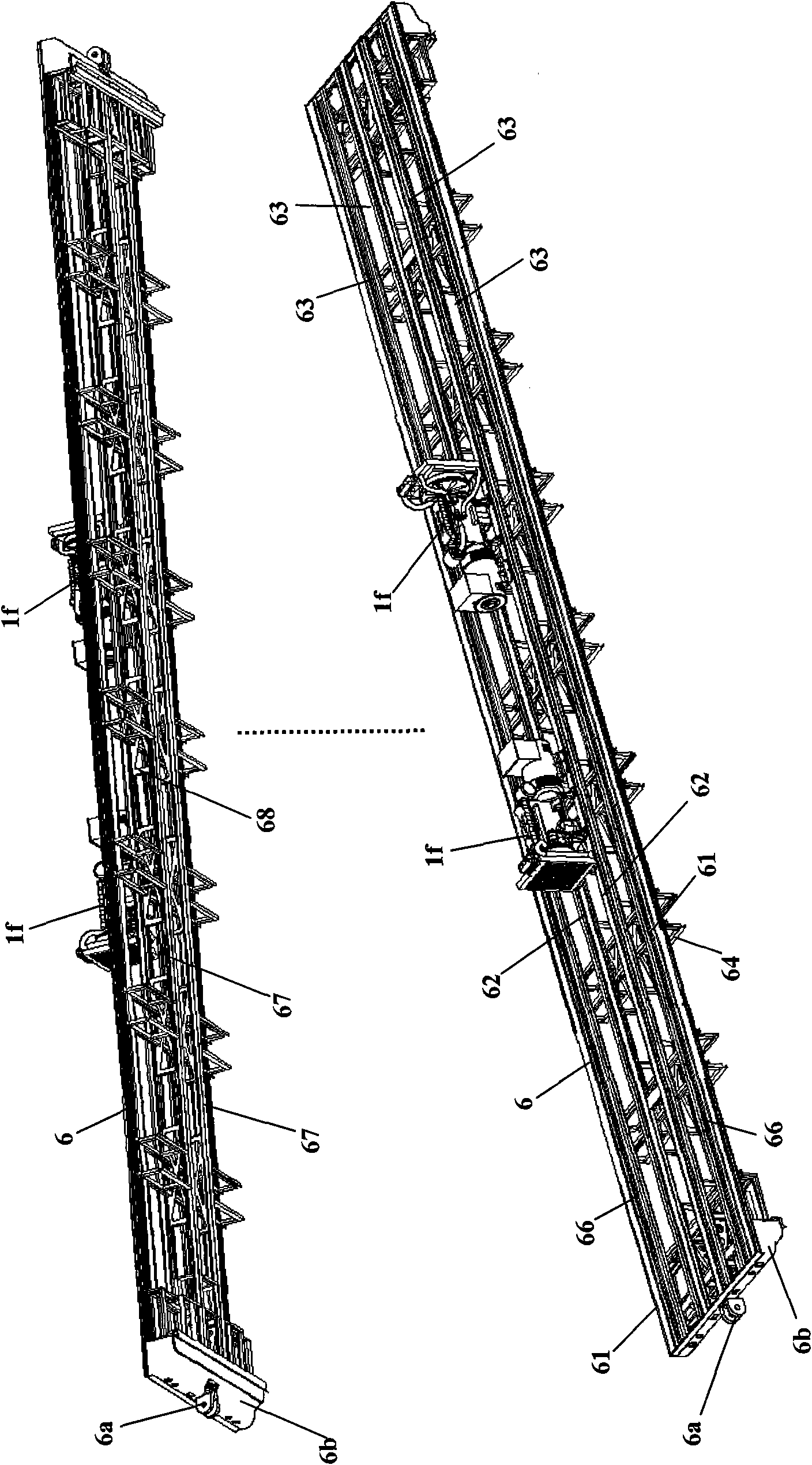

[0080] based on the following Figure 1 to Figure 10 , specify the preferred embodiment of the present invention:

[0081] Such as figure 1 As shown, the present invention provides a frame car body structure of a maglev track inspection car, which includes:

[0082] Carriage floor 6;

[0083] The compartment structure 1 is arranged on the compartment floor 6;

[0084] The lifting maintenance platform 3 is arranged on the carriage floor 6 and is located at both ends of the carriage structure 1;

[0085] The vehicle-ground communication equipment mounting bracket 4 is arranged on the compartment floor 6 and is located at both ends of the compartment structure 1;

[0086] On-vehicle hybrid power grid equipment 1f (such as figure 2 As shown), it is symmetrically arranged on the compartment floor 6 and is located in the compartment structure 1, which can balance the load of the vehicle. In this embodiment, the vehicle-mounted hybrid power grid equipment 1f is a diesel generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com