Cultivating substrate

A technology for cultivation substrates and impurities, applied in the field of agricultural organic resource utilization, can solve the problems of small quantity and high price, and achieve the effects of small engineering quantity, low price and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of lily cultivation medium of the present invention, concrete steps are as follows:

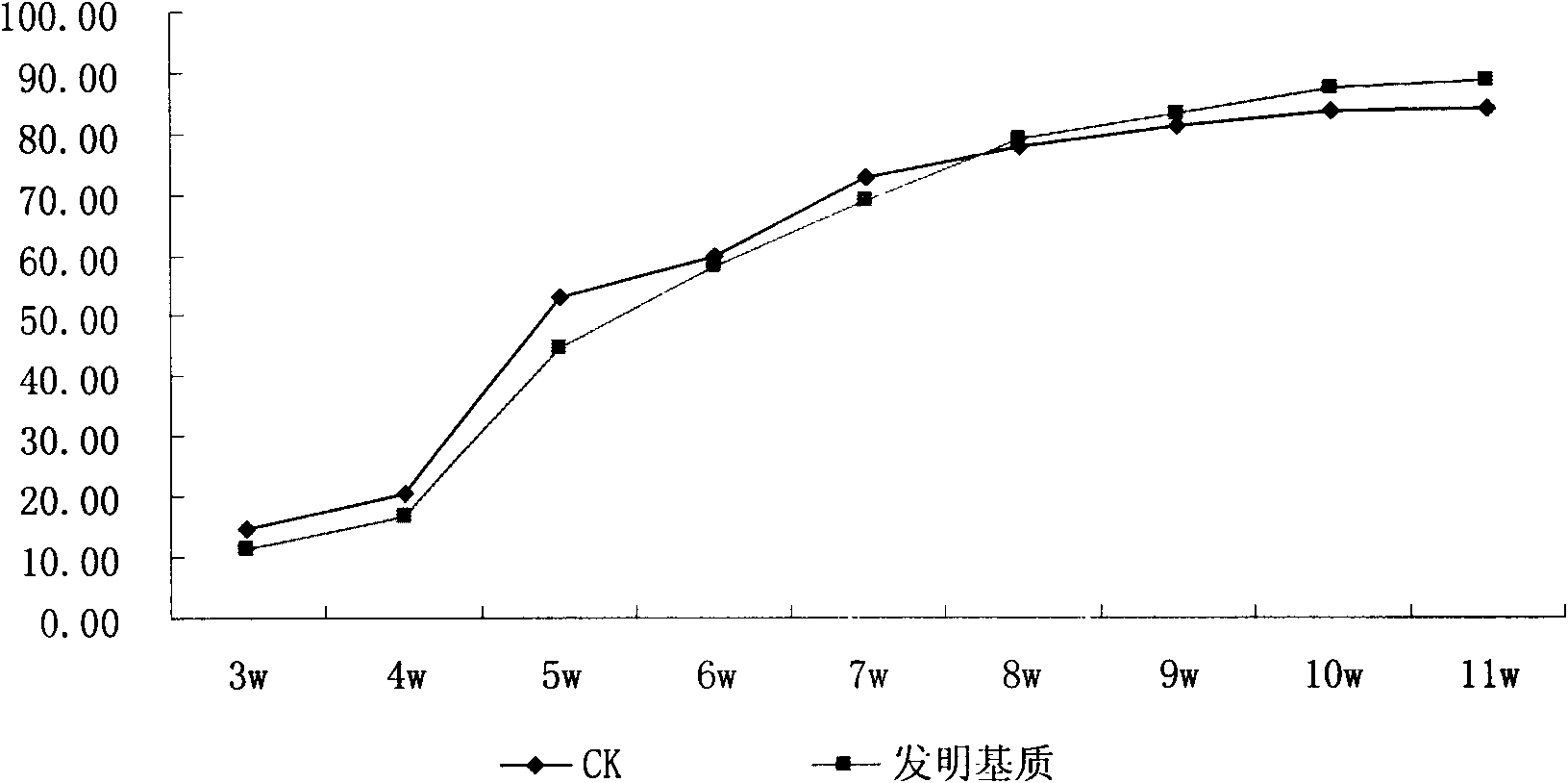

[0027] Taking the preparation of a lily cultivation medium with a volume of 10L as an example, each single component of coconut peat, sand, perlite and vermiculite is mixed in sequence according to the volume ratio of 3:3:2:2. At the same time, the usual cultivation substrate (7 peat: 3 perlite) was selected as the control (CK).

[0028] (1) Measure 3L coconut peat;

[0029] (2) Measure 3L of sand (medium particle size);

[0030] (3) Measure 2L of perlite (large particle size, rinse the dust with running water, and place it in a ventilated place to dry);

[0031] (4) Measure 2L of vermiculite (medium particle size);

[0032] (5) The above-mentioned individual components are fully mixed and set aside.

[0033] It needs to be pointed out that the total volume of each single component will decrease during the mixing process; in addition, the substrate must be watered a...

Embodiment 2

[0044] The preparation of lily cultivation medium of the present invention, concrete steps are as follows:

[0045] Taking the preparation of a lily cultivation medium with a volume of 9L as an example, each single component of coconut peat, sand, perlite and vermiculite is mixed in sequence according to the volume ratio of 3.5:2.5:1.5:1.5. At the same time, use the usual cultivation substrate in production (peat: perlite = 7:3 mixed substrate)

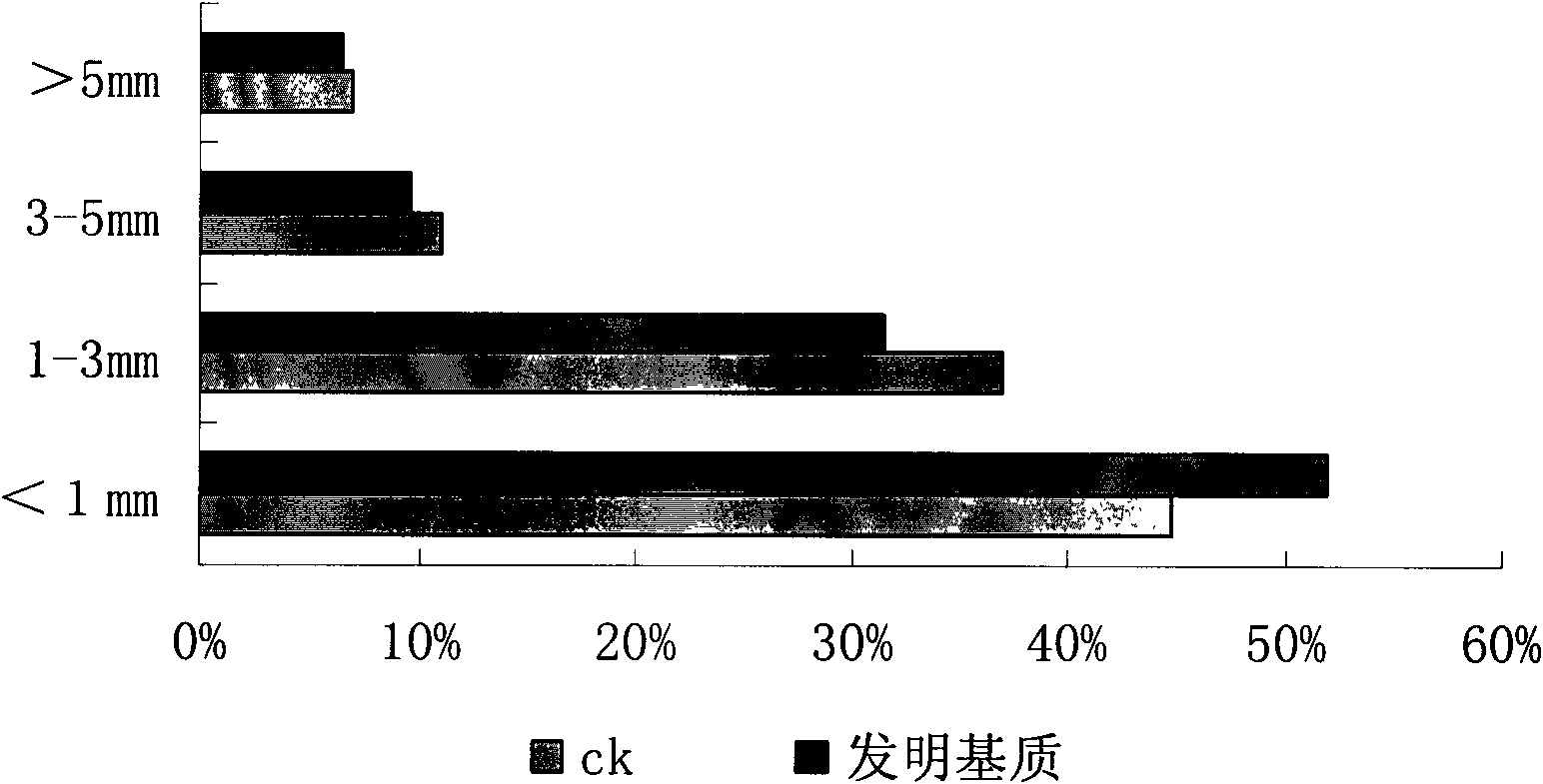

[0046] The particle size composition of the sand used is: 5mm accounts for 9%.

[0047] The particle size composition of the perlite used is: <1mm accounts for 7%; 1-3mm accounts for 64%; 3-5mm accounts for 29%.

[0048] The particle size composition of the vermiculite used is: <1mm accounts for 72%; 1-3mm accounts for 28%.

[0049] (1) Measure 3.5L coconut peat;

[0050] (2) Measure 2.5L sand;

[0051] (3) Measure 1.5L perlite (wash the dust with running water, place it in a ventilated place to dry);

[0052] (4) Measure 1.5L ve...

Embodiment 3

[0057] The preparation of lily cultivation medium of the present invention, concrete steps are as follows:

[0058] Taking the preparation of a lily cultivation medium with a volume of 10L as an example, each single component of coconut peat, sand, perlite and vermiculite is mixed in sequence according to the volume ratio of 2.5:2.5:2.5:2.5.

[0059] (1) Measure 2.5L coconut peat;

[0060] (2) Measure 2.5L sand (medium particle size);

[0061] (3) Measure 2.5L perlite (large particle size, rinse the floating dust with running water, and place it in a ventilated place to dry);

[0062] (4) Measure 2.5L vermiculite (medium particle size);

[0063] (5) The above-mentioned individual components are fully mixed and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com