Deficiency ultrasonic detecting equipment of mechanical equipment based on wavelet theory

A mechanical equipment and ultrasonic testing technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as unsuitable for on-site use and time-consuming, and achieve the effects of improving measurement accuracy, sensitivity, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

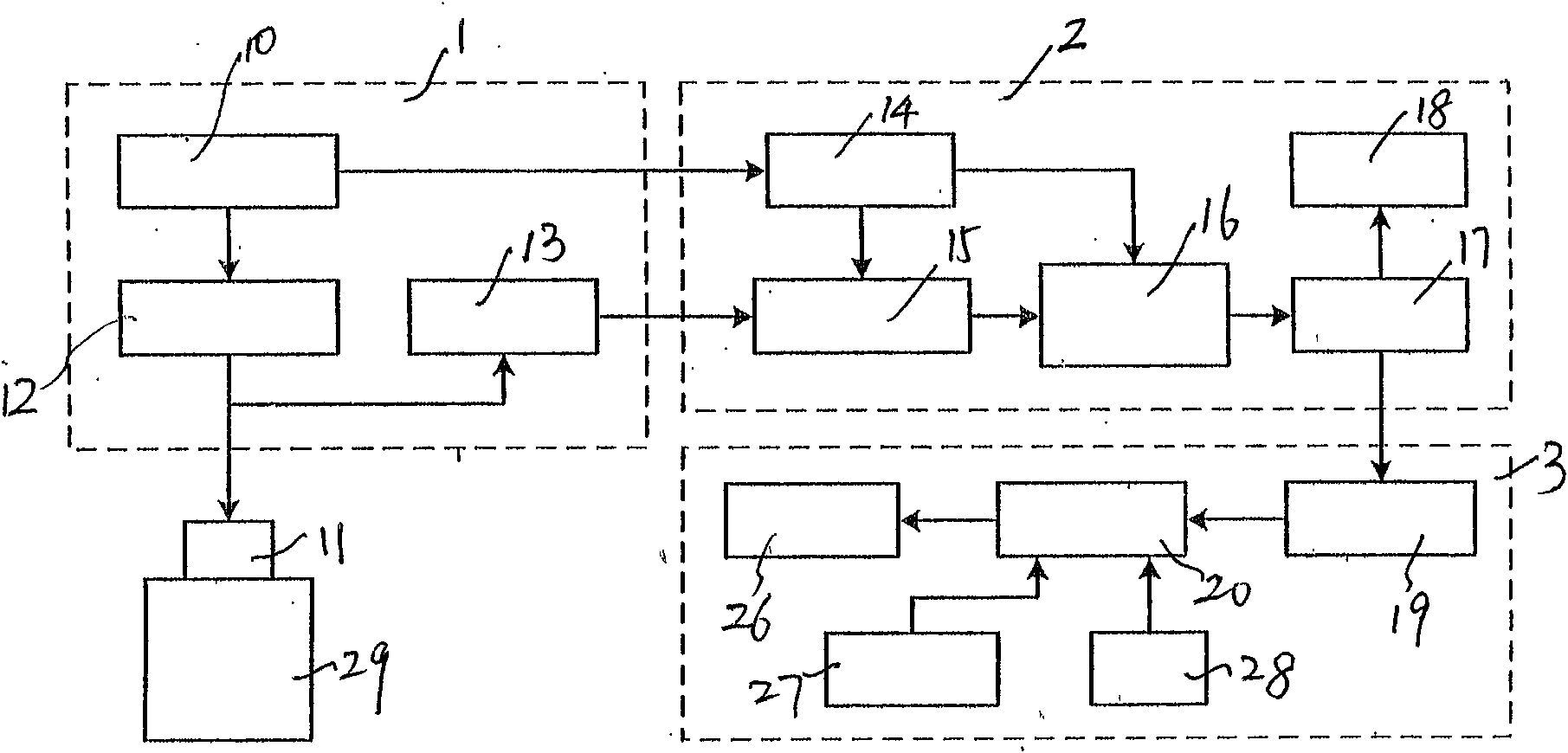

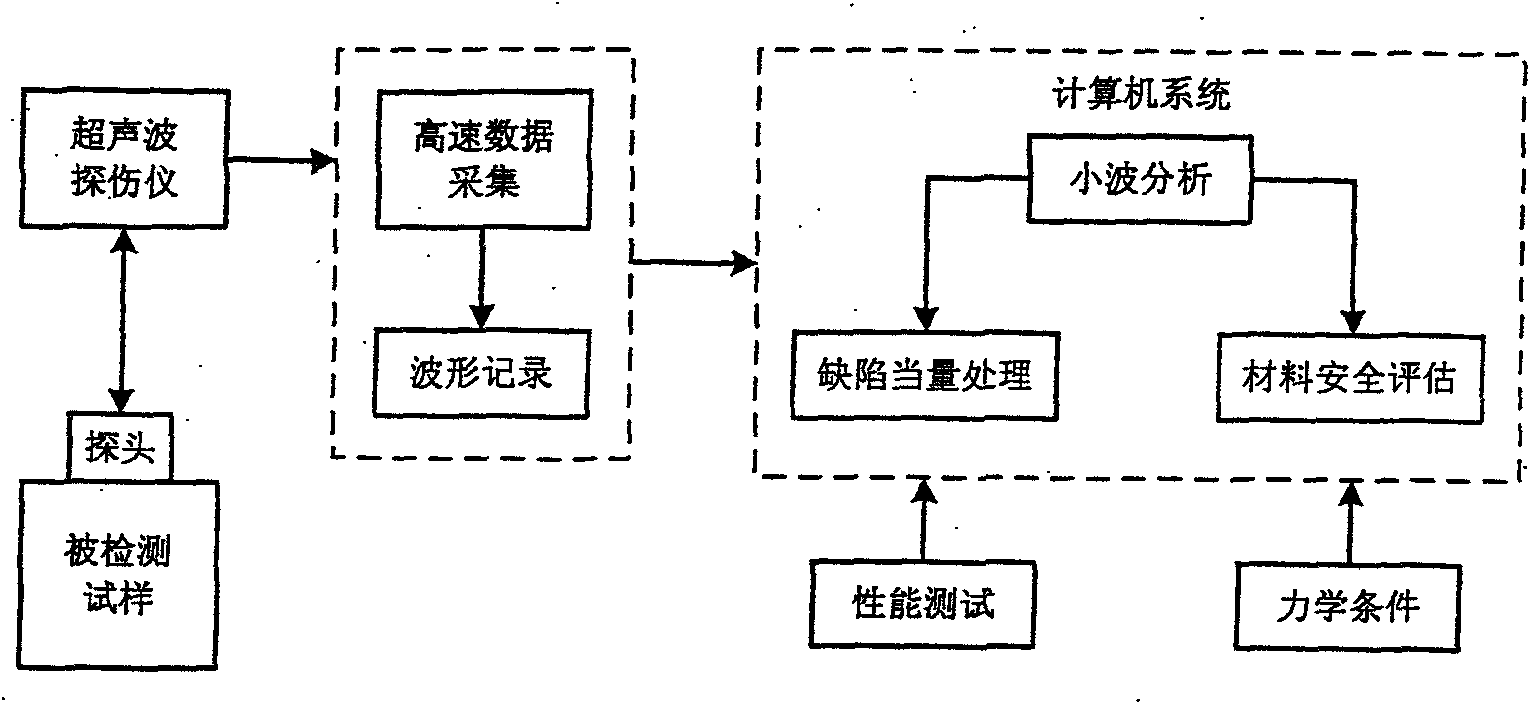

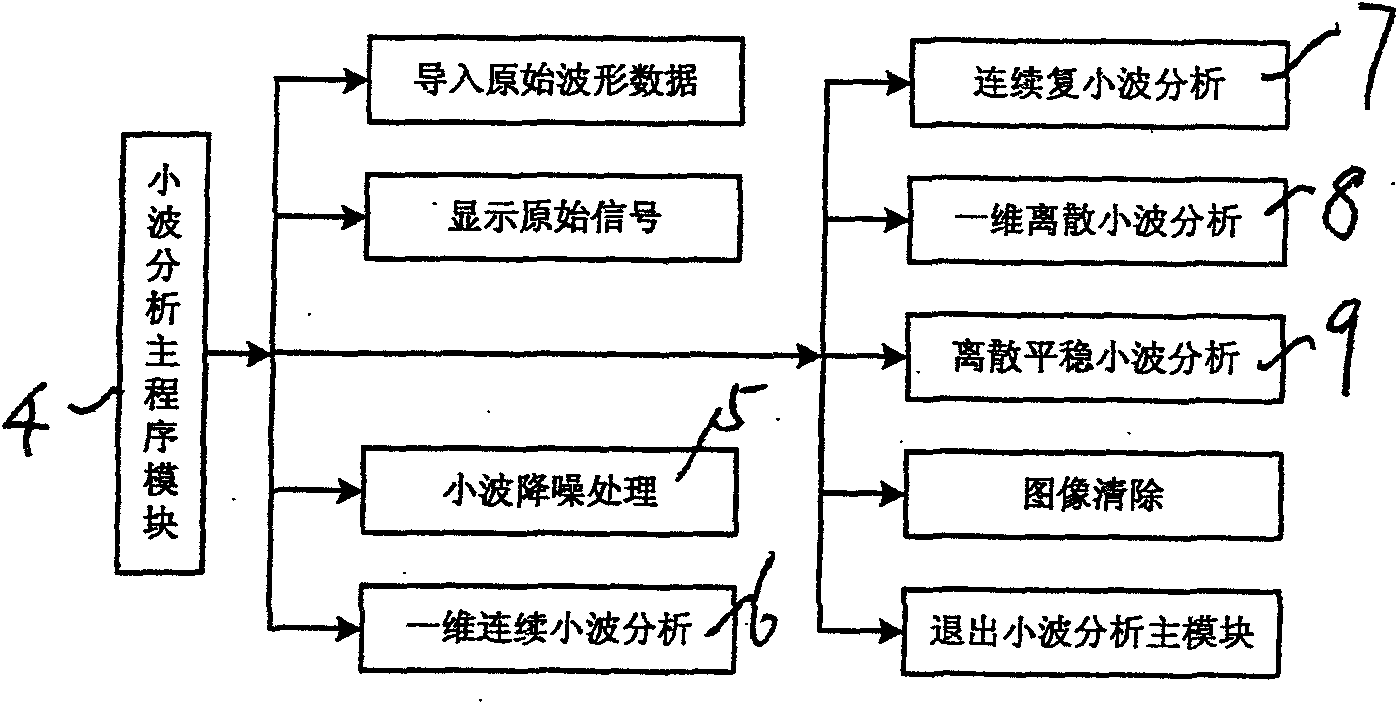

[0029] An ultrasonic testing device for defects in mechanical equipment based on wavelet theory, comprising an ultrasonic flaw detector 1 connected to a digital storage oscilloscope 2 for processing ultrasonic echo video signals obtained by the ultrasonic flaw detector, and the digital storage oscilloscope communicates via serial The function transmits the detected ultrasonic data acquisition signal to the internal memory of the microcomputer 3, and stores it in the external memory of the microcomputer in the form of a file name, and processes the data file by the system function module 4 (ie, the main program module of wavelet analysis) The system function module includes the wavelet denoising processing program module 5 that carries out noise reduction processing to the imported file, the one-dimensional continuous wavelet analysis program module 6 that carries out the one-dimensional continuous wavelet analysis to the imported file, and performs continuous processing on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com