Method for testing control of accelerating corrosion of steel reinforcement in chlorine salt corrosion concrete

An accelerated corrosion and control test technology, applied in the fields of weather resistance/light resistance/corrosion resistance, material inspection products, measuring devices, etc., can solve the problems of short time required, inconsistent test parameters, content and steps, poor control operability, etc. problems, to achieve the effects of easy processing and production, promotion of popularization and application, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

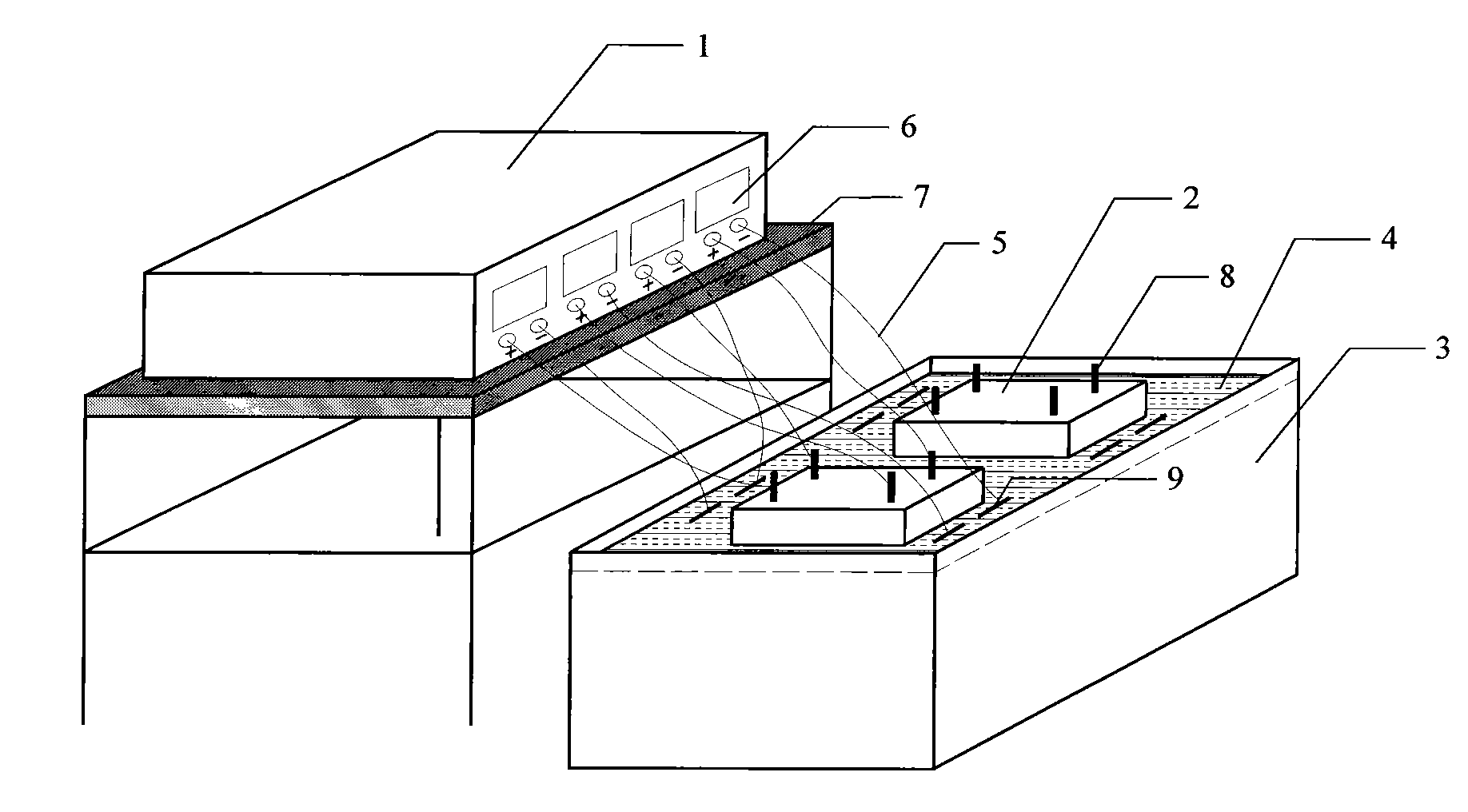

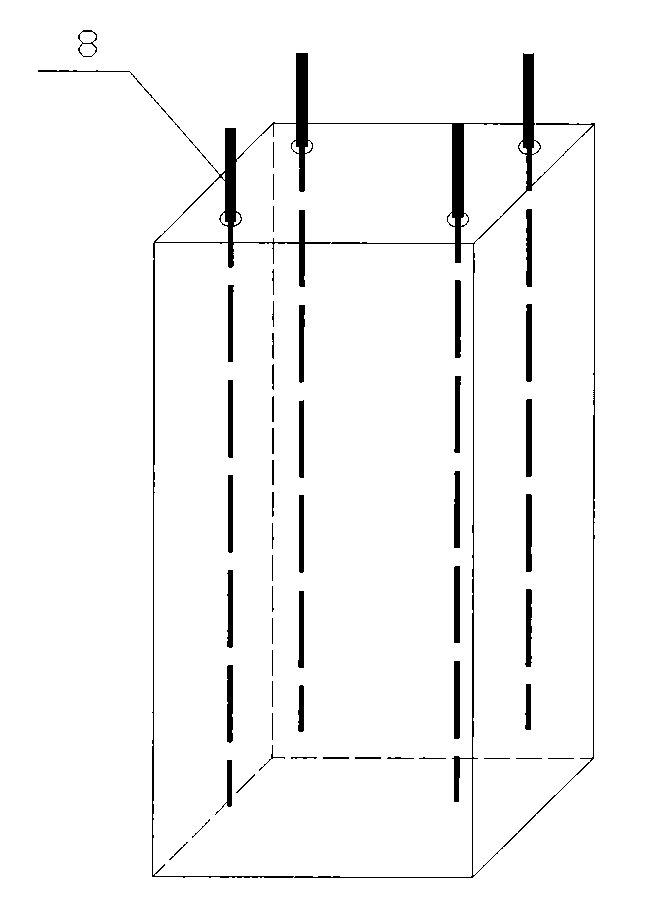

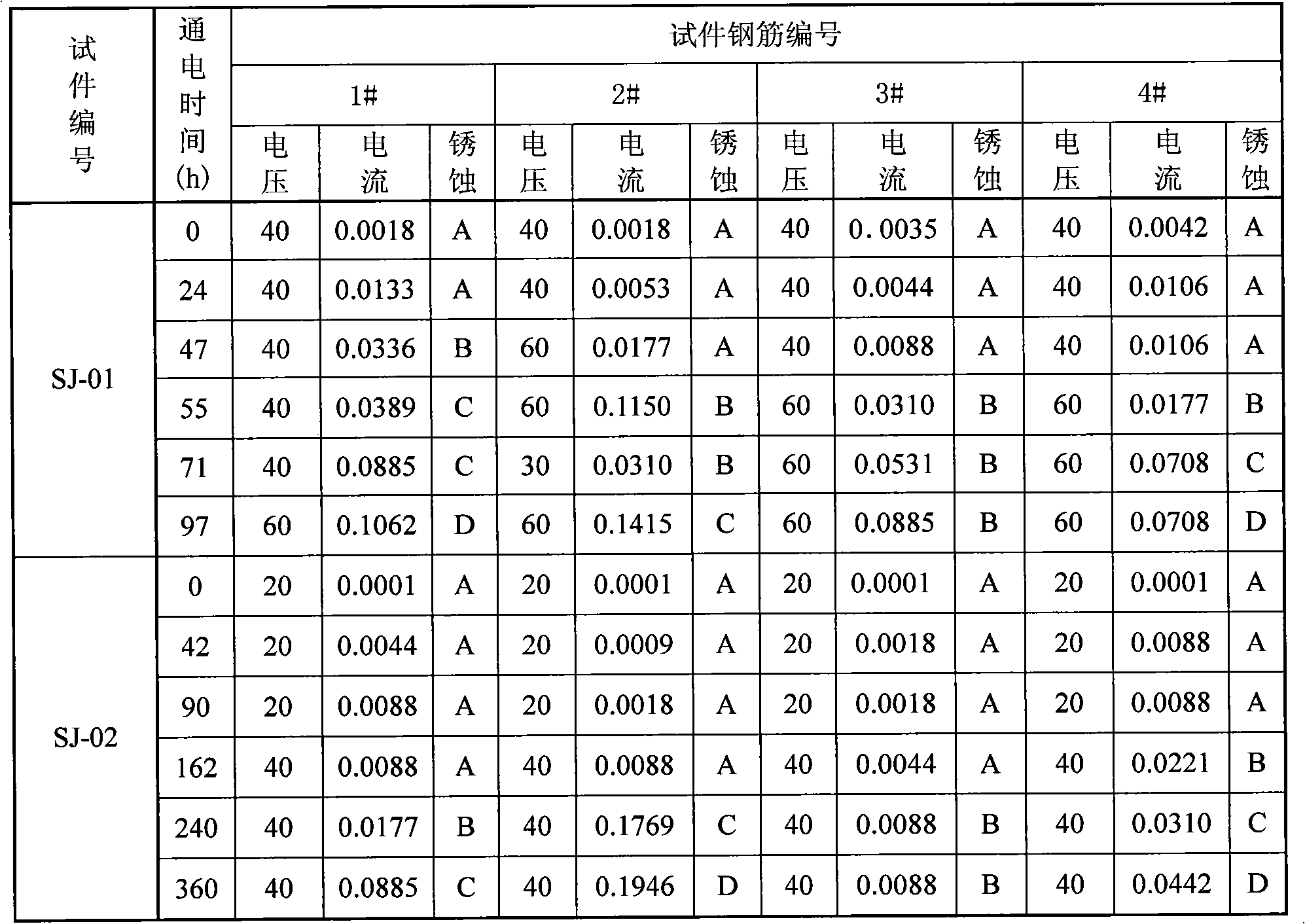

[0021] Such as Figure 1 ~ Figure 2 As shown, a test method for the accelerated corrosion control of steel bars in chloride-corroded concrete, the method adopts a multi-channel DC stabilized power supply 1, two standard specimens for the control of accelerated corrosion of steel bars in concrete 2, a chloride salt solution test box 3. Solution 4. Test the energized wire 5, the test bench 7, and the electrochemical reaction cathode steel bar 9 for the test. The multi-channel DC stabilized power supply 1 is placed on the test bench 7. The standard test for the accelerated corrosion control of steel bars in the concrete The size of piece 2 is 150mm×150mm×300mm, and it is composed of concrete and four steel bars 9. The four steel bars 9 have a diameter of 12mm and a length of 300mm, of which 50mm is the extended section and 250mm is the buried section. The thickness of the concrete protective layer around the four steel bars 9 is 30mm (when testing in combination with the actual pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com