Method for manufacturing metal nanometer particle

A technology of metal nanoparticles and manufacturing methods, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy precipitation, large particle size, poor dispersion, etc., and achieve simplified procedures and particle size evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0036] In a solvent mixture consisting of 10ml of ultrapure water, 90ml of ethylene glycol, 5ml of 2-pyrrolidone as a polar solvent, and 4g of polyvinylpyrrolidone (PVP) with a molecular weight of 20,000 or more, dissolve 0.1 mole of Precursor CuSO 4 Finally, 0.2 mol of triethylamine was added and forced stirring was performed until the green mixed solution became a gel-like green substance. Thereafter, 0.1 mol of hydrazine was slowly added over 10 minutes, and forced stirring was performed until the solution turned reddish black or deep red. The reaction temperature at this time was maintained at 25°C.

[0037] Reclaim red and black powder by centrifugation, wash and reclaim several times with acetone and water, and finally mix into metal nano powder 30% by weight and then stored.

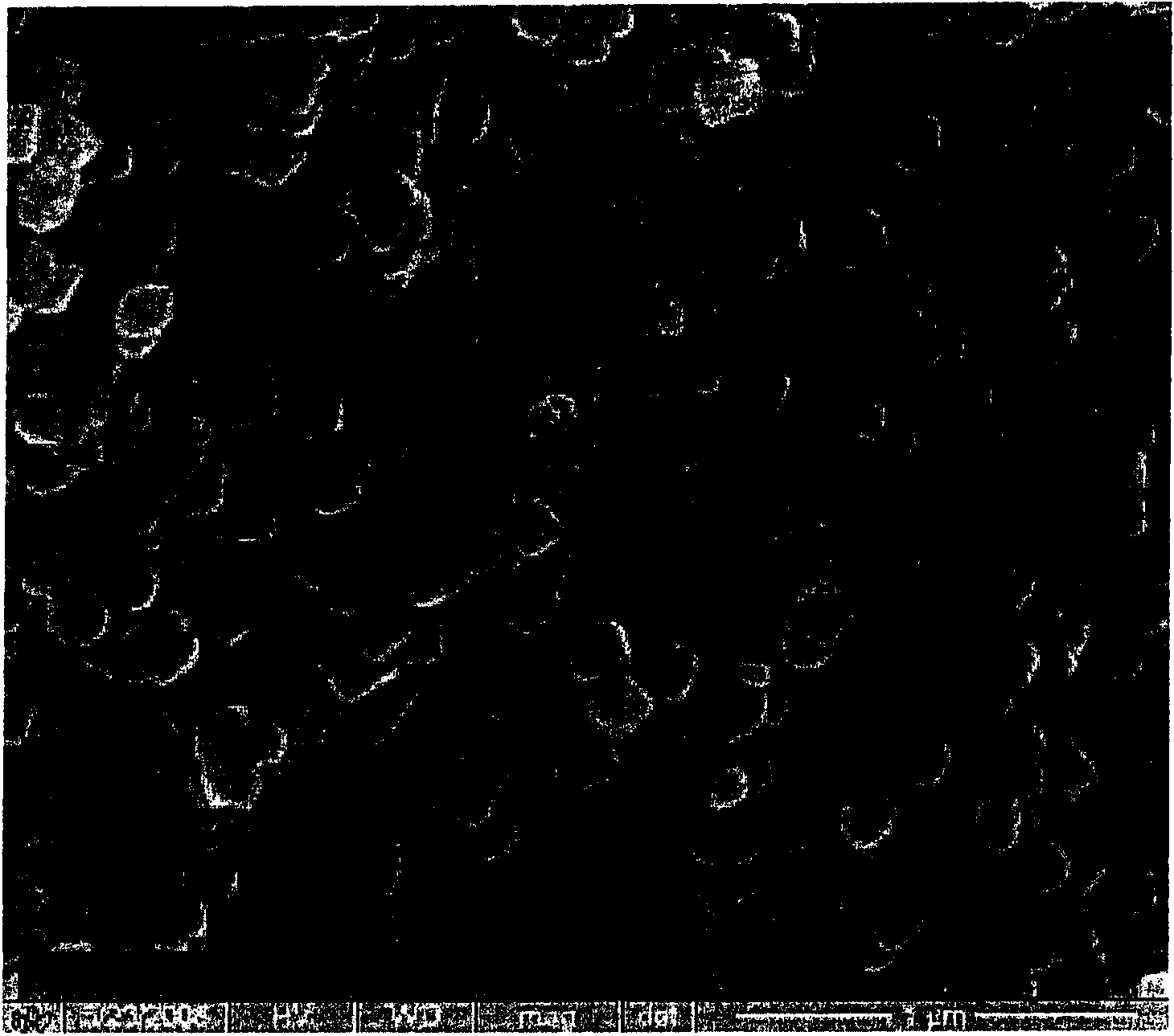

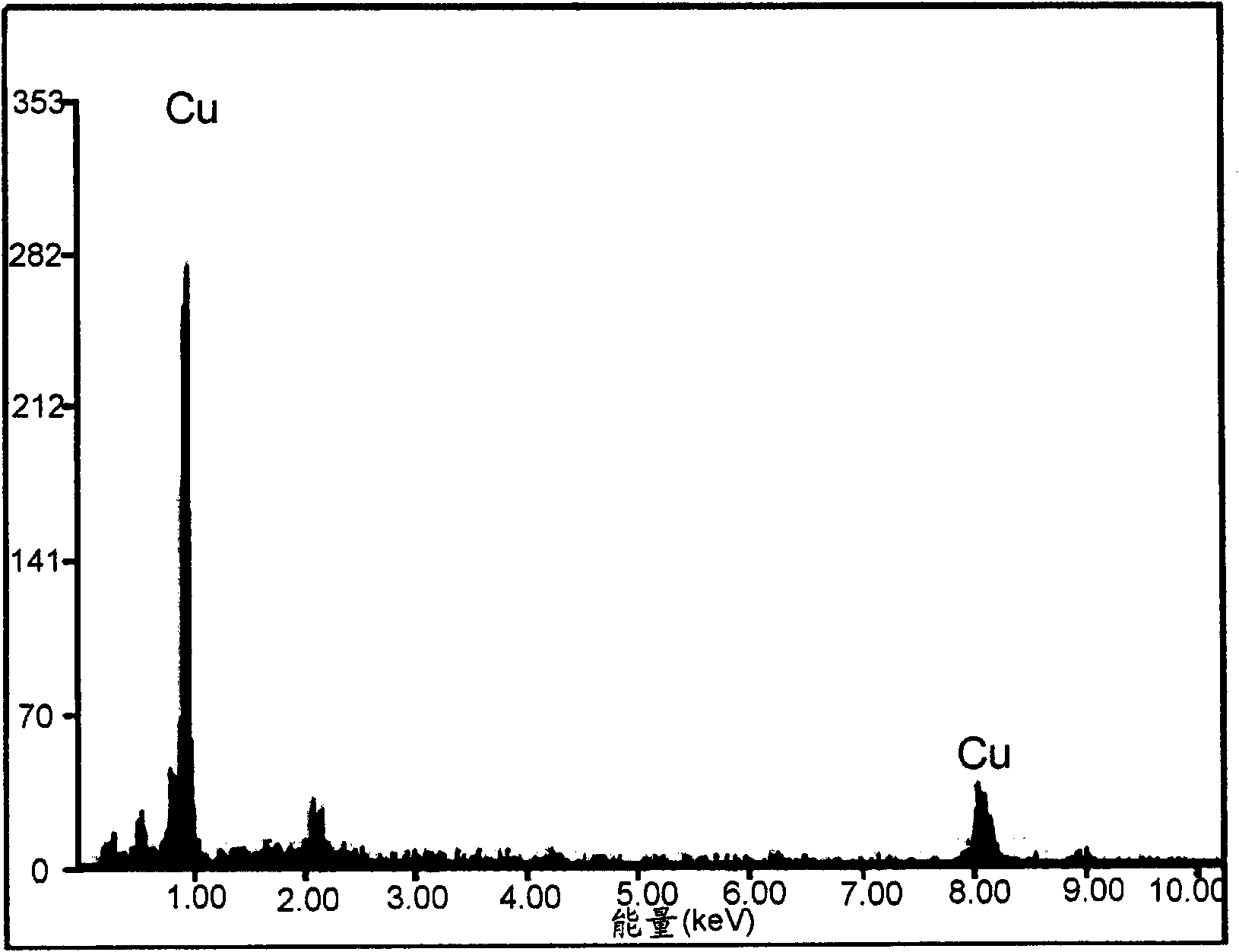

[0038] As a result of observing the particle size of the metal nanopowder by SEM, it was confirmed that it had a particle size distribution of 50 to 80 nm.

experiment example 2

[0040] In a solvent mixture consisting of 10 ml of ultrapure water, 90 ml of diethylene glycol, 5 ml of N-methylpyrrolidone as a polar solvent, and 4 g of PVP with a molecular weight of 20,000 or more, dissolve 0.1 mole of CuSO as a metal precursor by forced stirring 4 Finally, 0.1 mol of triethanolamine was added, and forced stirring was performed until the green mixed solution became a gel-like green substance. Thereafter, after raising the temperature of the solution to 50° C., wait for the temperature to stabilize, slowly add 0.1 mol of hydroxylamine in 10 minutes, and perform forced stirring until the solution turns deep red. The crimson powder is recovered by centrifugation, washed and recovered several times with acetone and water, and finally mixed into a metal nano-powder. 30% by weight and then stored.

[0041] As a result of observing the particle size of the metal nanopowder by SEM, it was confirmed that figure 1 Shown has a uniform particle size distribution of ...

experiment example 3

[0043] In a solvent mixture composed of 10 ml of ultrapure water, 90 ml of ethylene glycol, 5 ml of N-methylformamide as a polar solvent, and 4 g of PVP with a molecular weight of 20,000 or more, 0.1 mole of PVP as a metal precursor was dissolved by forced stirring. CuSO 4 Finally, 0.1 mol of diethylamine was added and forced stirring was performed until the green mixed solution became a gel-like green substance. Thereafter, 0.1 mol of 30% hydrazine in an ultrapure aqueous solution was slowly added over 10 minutes, and forced stirring was performed until the solution turned deep red. The crimson powder is recovered by centrifugation, washed and recovered several times with acetone and water, and finally mixed into a metal nano-powder. 30% by weight and then stored.

[0044] As a result of observing the particle size of the metal nanopowder by SEM, it was confirmed that it had a particle size distribution of 50 to 90 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com