Processing method for thin paint film enamelled flat wire

A technology of enameled flat wire and processing method, which is applied to electrical components, circuits, and conductor/cable insulation, etc., can solve the problems of poor heat dissipation performance of paper-wrapped winding wires, many layers of outer insulating paper, and large external dimensions, etc. Achieve the effect of reducing the number of layers of insulating paper wrapping paper, not easy to block oil passages, and high insulation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

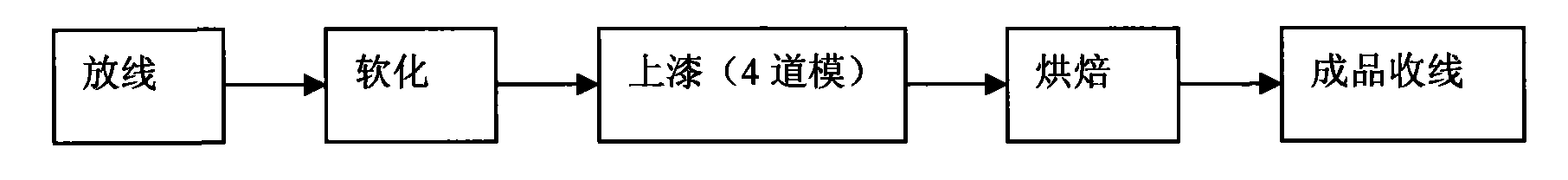

[0026] A processing method of thin paint film enamelled flat wire according to the present invention, see accompanying drawing, this processing method comprises the following steps:

[0027] 1) Lay out the copper wire;

[0028] 2) Soften the copper wires; when the copper wires are softened, the temperature of the softening furnace is controlled at 560-650°C for the upper layer and 560-650°C for the lower layer. The temperature of the softening furnace is 380-650°C for the upper layer, 400-650°C for the middle layer, and 420-650°C for the lower layer.

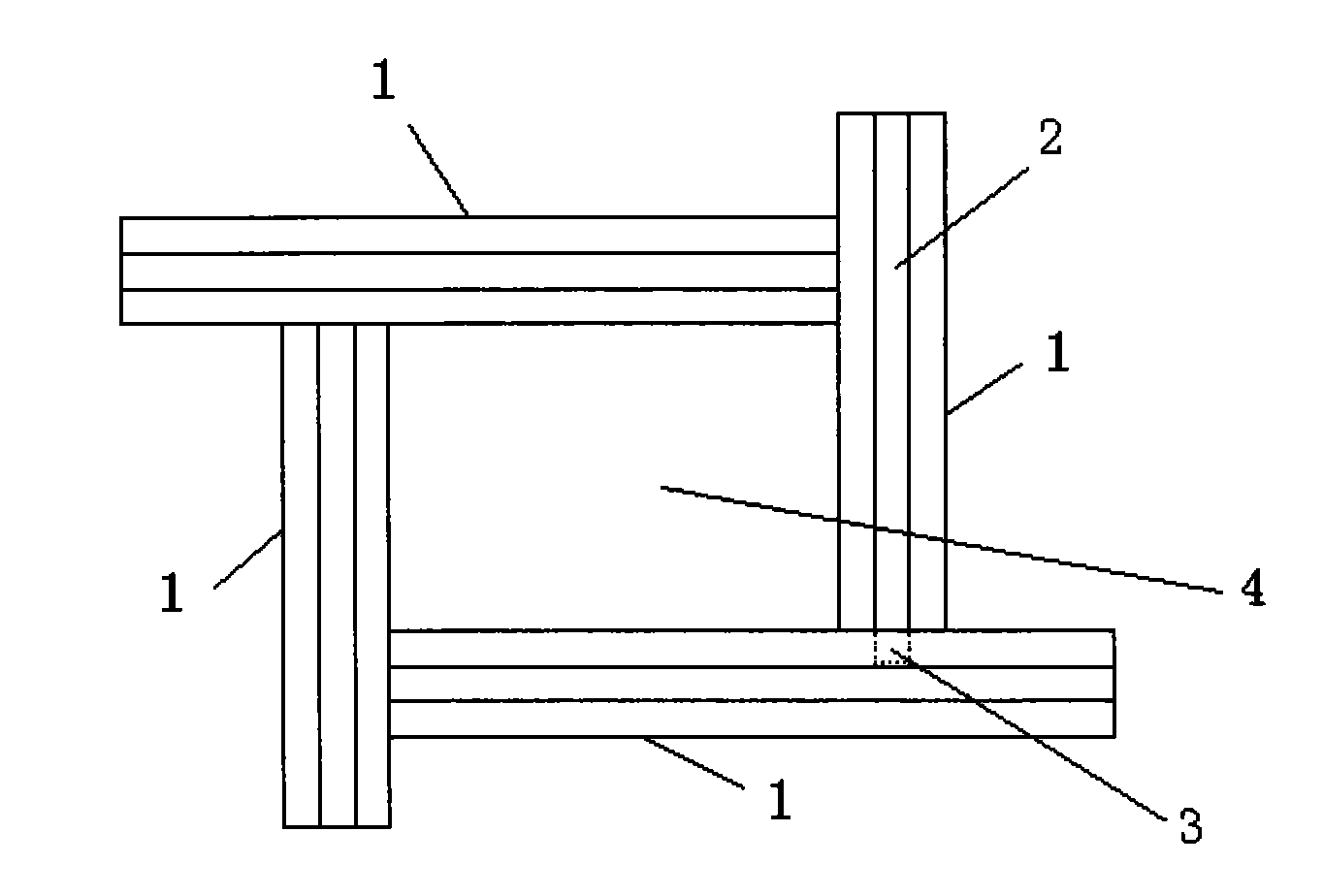

[0029] 3) The treated copper wire is subjected to four paint-scraping die-painting treatments. The enameled wire painting movable mold is used for four paint-scraping mold painting treatments. The movable abrasive tool is composed of a group of four hard alloy strips 1, which

[0030] The alloy bar 1 is provided with a chute 2 in the axial direction, and a sliding head 3 matching with the chute 2 is provided at one end of a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com