Test method of chip junction temperature in LED illumination lamps

A technology of LED lamps and LED chips, which is applied in the directions of radiation pyrometry, measuring device, optical radiation measurement, etc., can solve the problems of large gap width error, measurement value movement, high cost, etc., and meet the requirements of junction temperature measurement accuracy and determination The effect of improving accuracy and overcoming the large error of luminous peak position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the embodiments and accompanying drawings.

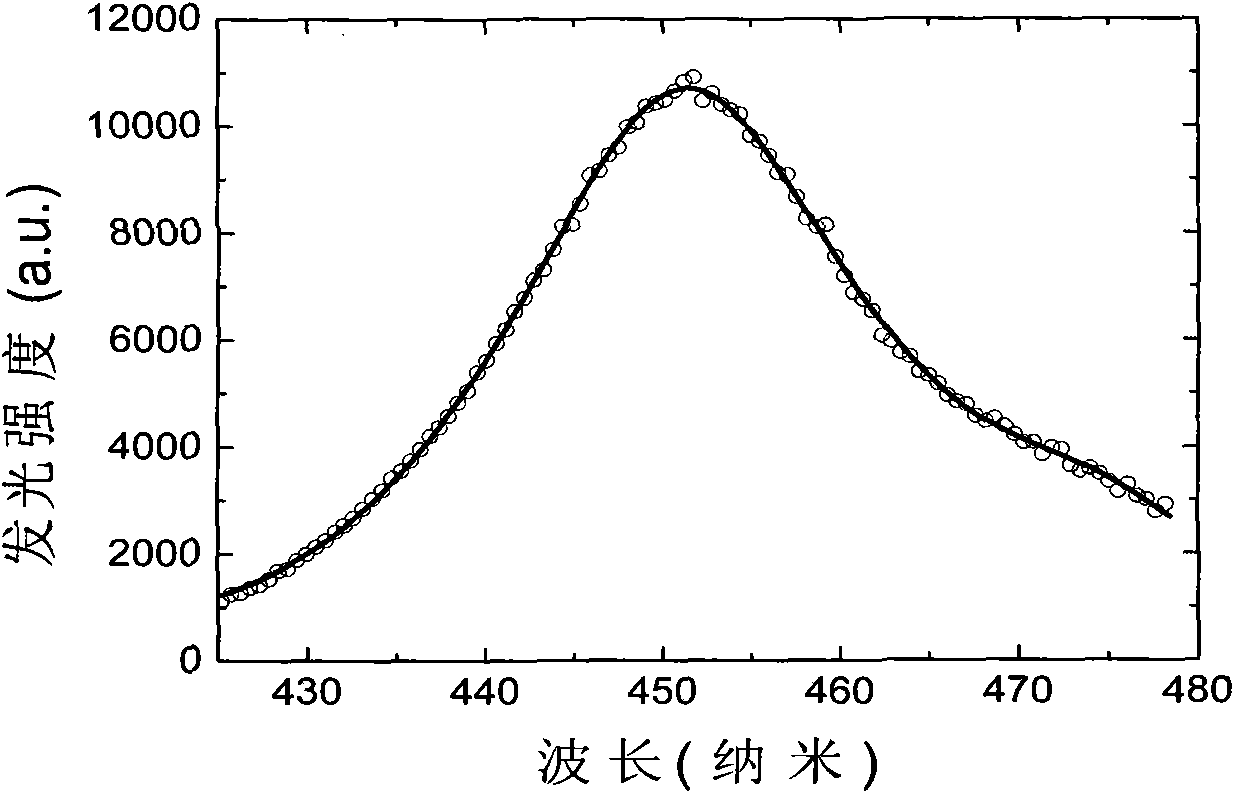

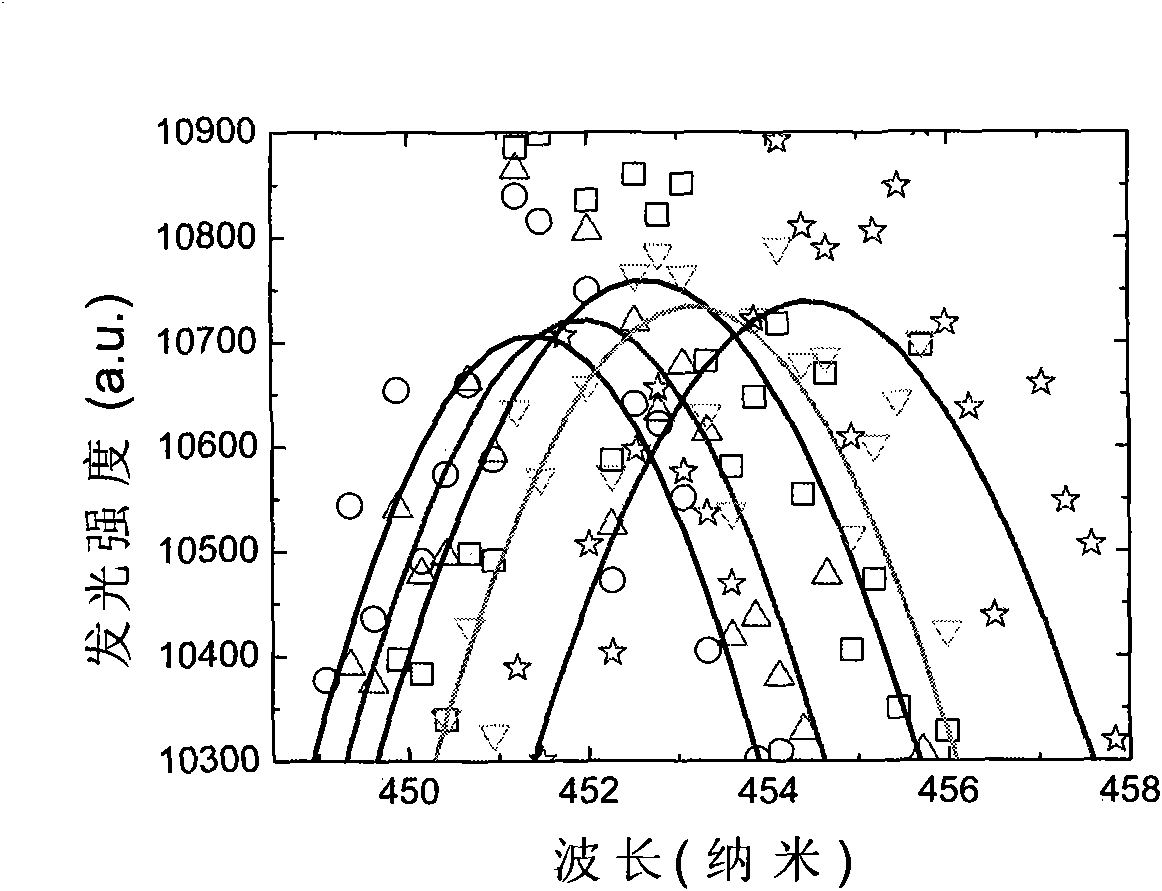

[0025] 1. Connect the LED lamp to be tested to emit light. The rated power of the LED lamp is 100 watts, and the rated voltage is 32~34 volts. In this example, a 33V regulated voltage source is used for power supply. The duty cycle of the voltage source is 1% and DC. model. The light emitted by the lamp is directly introduced into the spectrometer through the optical fiber. The application of spectrometer can get LED lamps such as Figure 4 The spectrum shown in the inset is very similar to the spectrum obtained by the two power supply modes of 1% and DC, but there is a small shift in the spectral peak at about 450 nm, which is due to the junction temperature of the two power supply modes Because of the difference, the present invention is to determine the movement amount with high precision.

[0026] 2. Under the action of pulse power supply with low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com