Liquid thermostat tank without stirrer

A constant temperature tank and agitator technology, applied in the direction of water bath/sand bath/air bath, etc., can solve the problem of small effective measurement volume of constant temperature tank, improve anti-interference ability and temperature stability and uniformity, increase effective Space, the effect of solving calibration difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

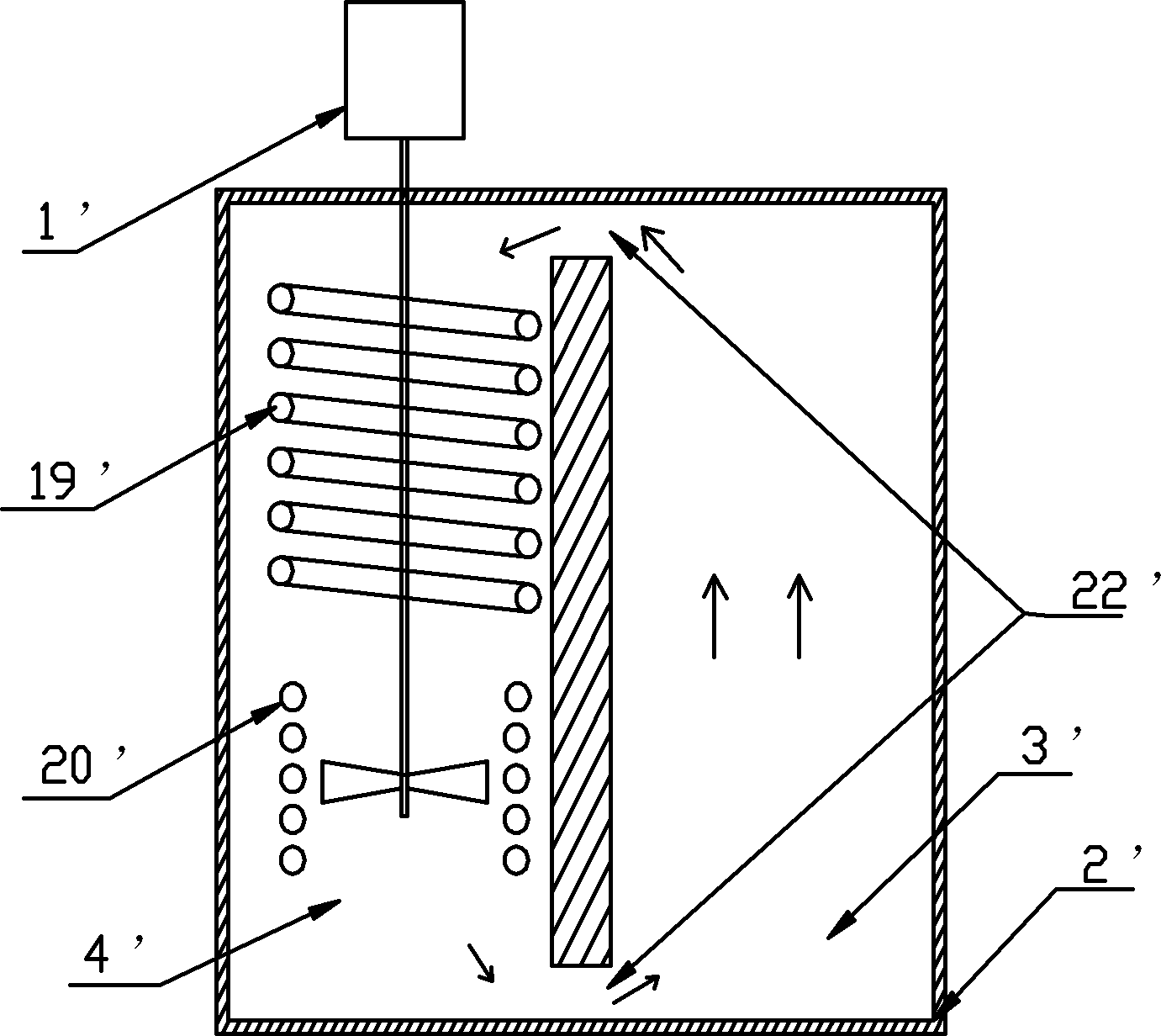

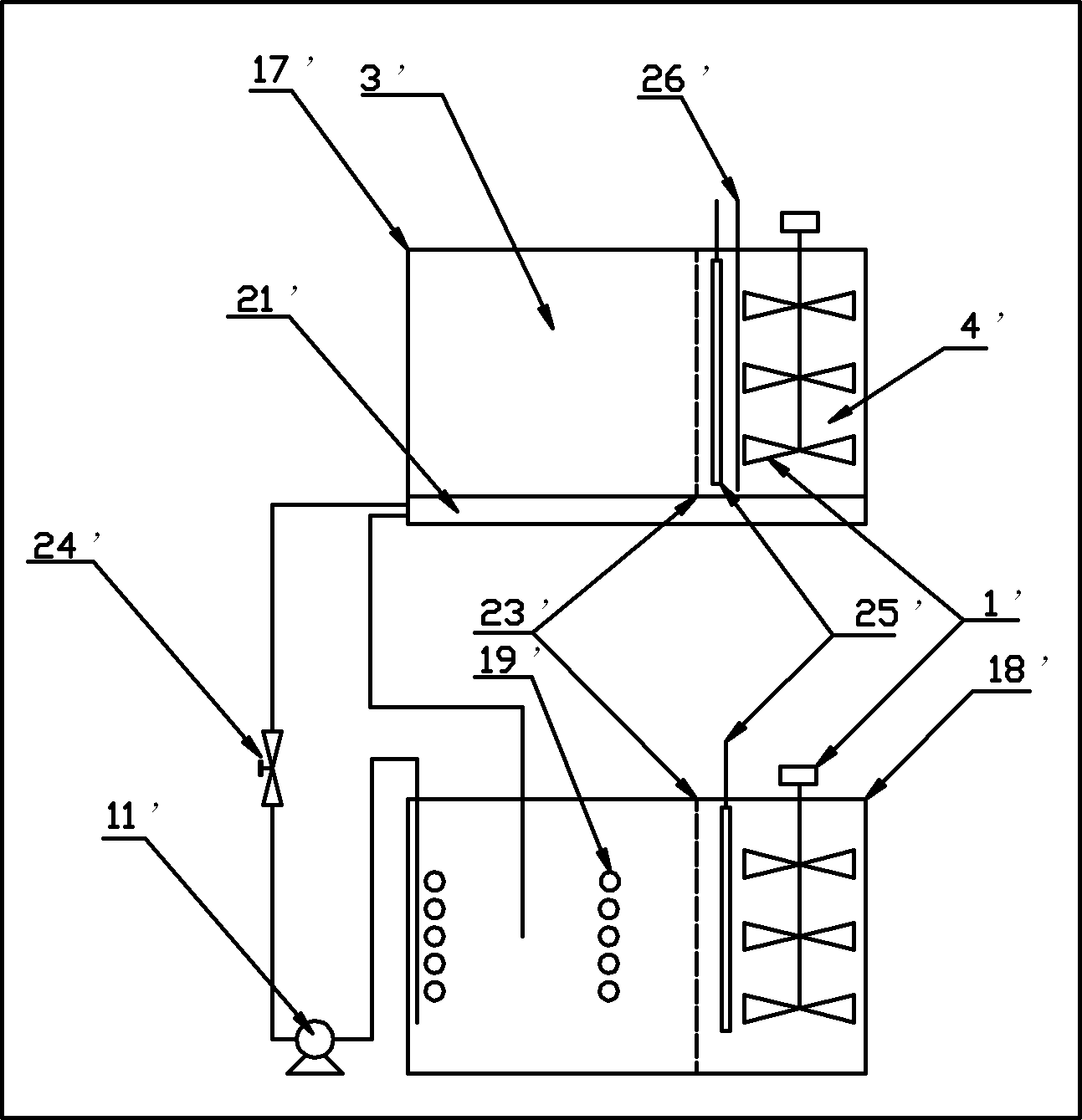

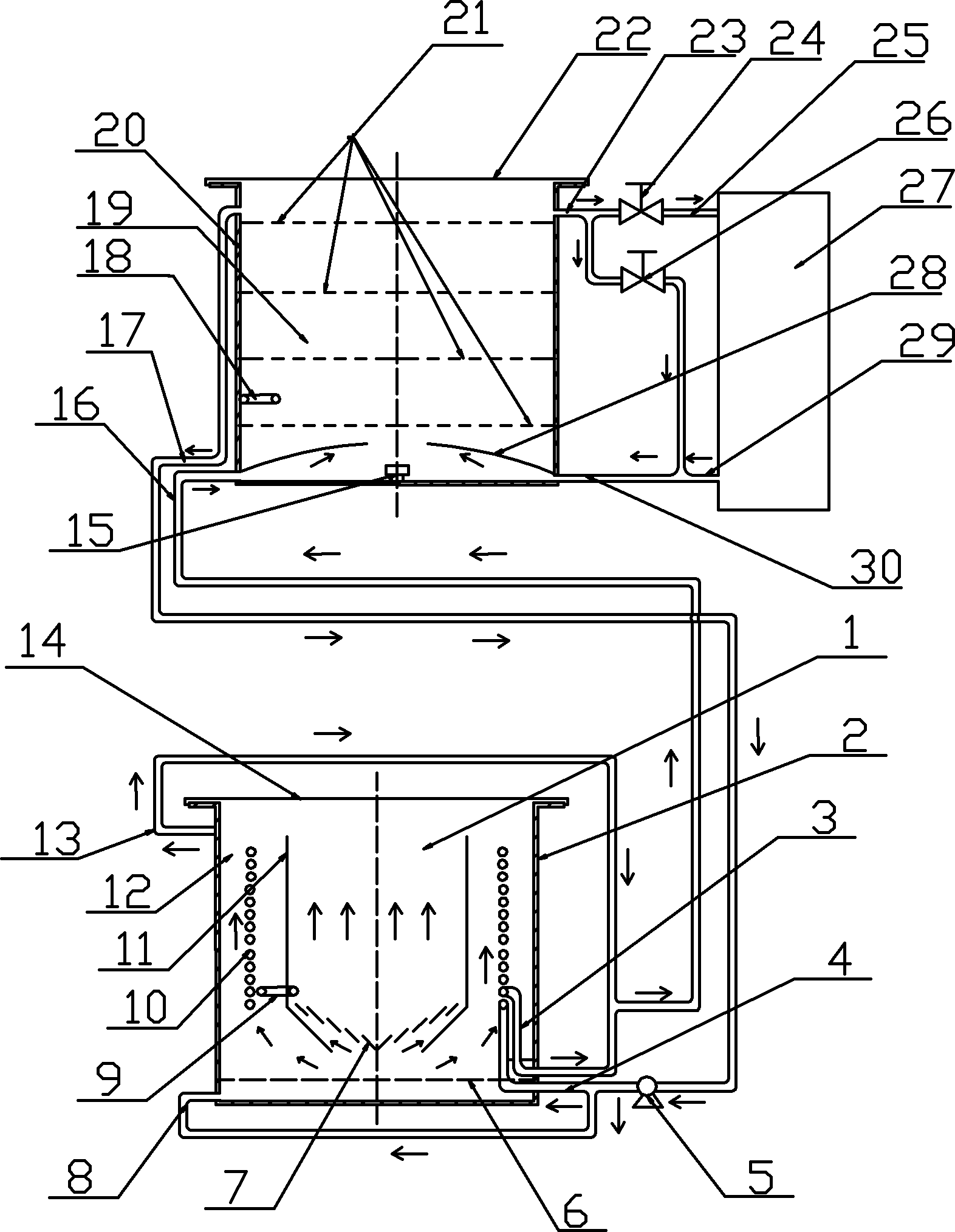

[0046] Such as image 3 Shown is a schematic structural view of the liquid constant temperature bath without agitator of the present invention. For precision temperature-controlled thermostats, there are two main requirements: (1) the temperature must remain stable during the calibration process; (2) the temperature must be uniform throughout the control volume.

[0047] The present invention is a liquid constant temperature tank without agitator, which is composed of a main constant temperature tank 2 and an auxiliary constant temperature tank 20 . Wherein the main constant temperature tank 2, i.e. the main body of the constant temperature tank, is used to complete the main function of the constant temperature tank. The constant temperature tank 2 is divided into upper and lower parts by a perforated rectification grid 6 in the vertical direction, of which the upper half is divided into the working area 1 and the temperature adjustment area 12 in the radial direction, with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com