Magnetic/functionalized SiO2 composite microsphere immobilized enzyme and preparation method thereof

A technology of composite microspheres and silica, which is applied in the direction of microsphere preparation, immobilization on or in inorganic carriers, microcapsule preparations, etc., can solve the problems of difficult recycling and reuse, and achieve improved operational stability, good biological Compatibility, the effect of easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

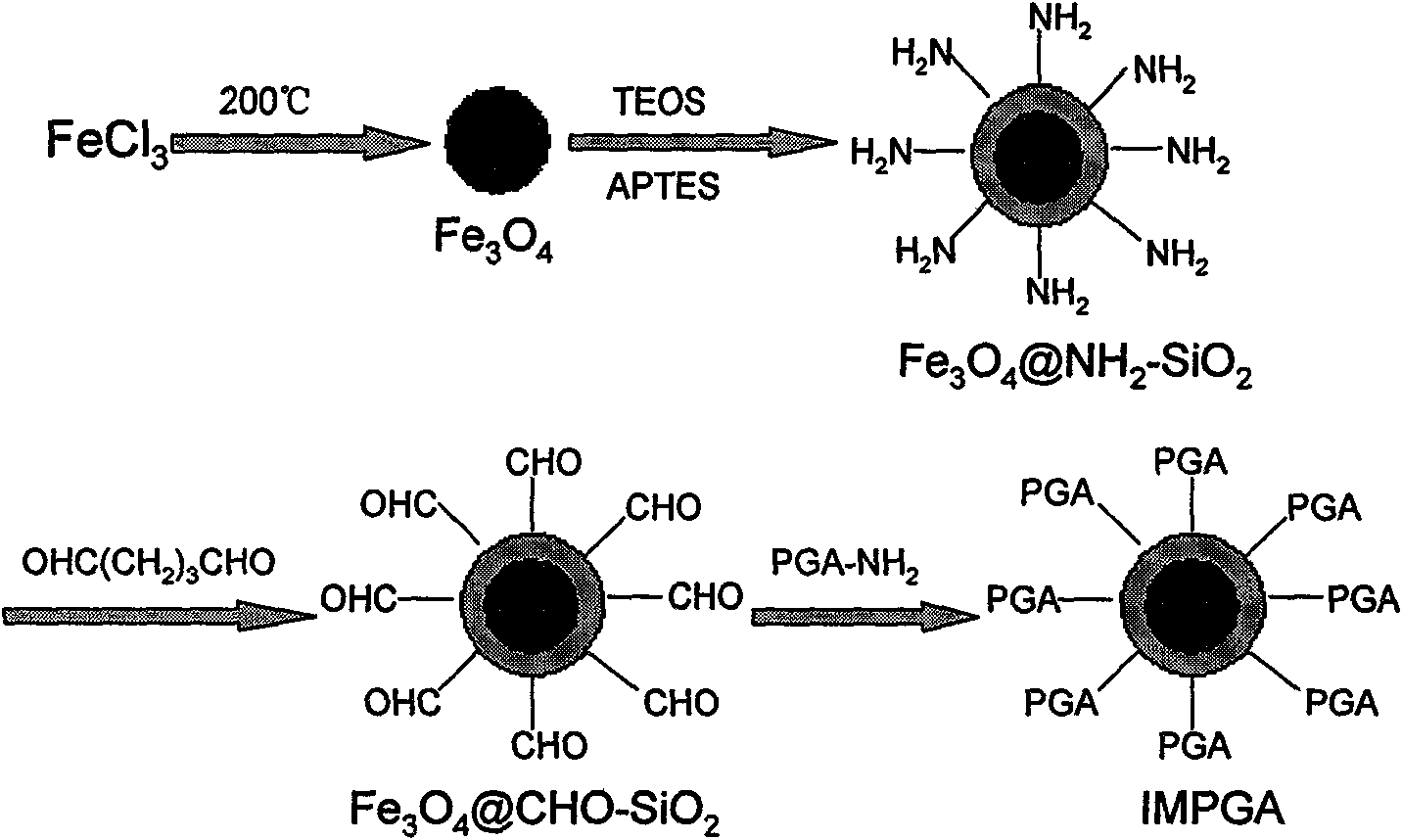

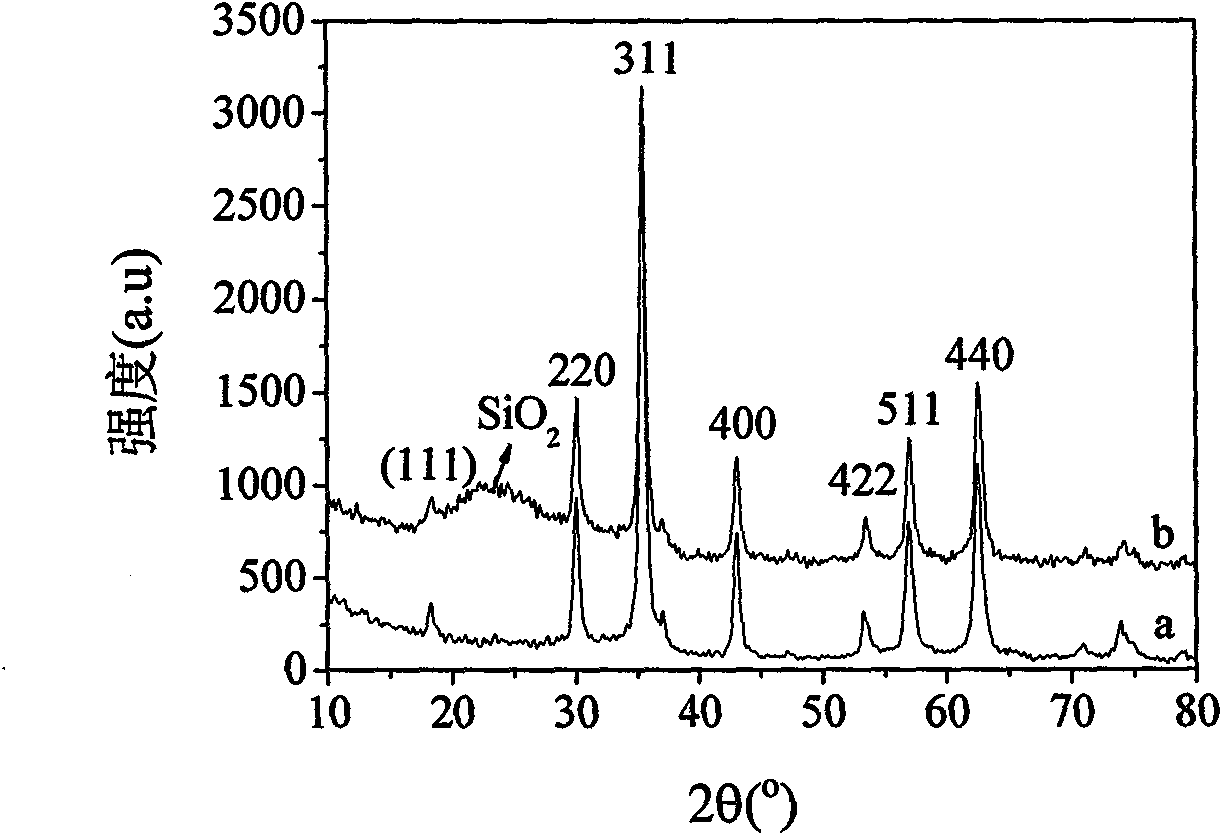

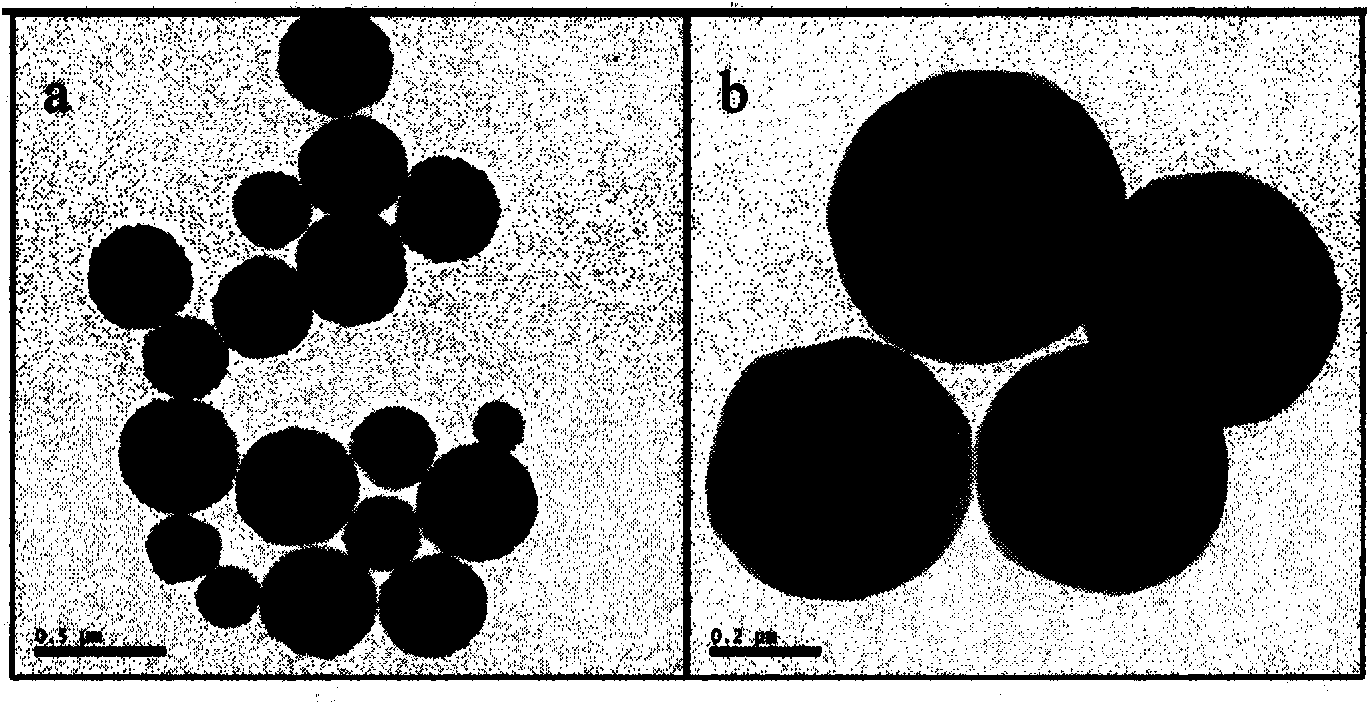

[0020] 5.40g FeCl 3 ·6H 2 O, 200mL of ethylene glycol and 14.40g of sodium acetate were stirred evenly, then transferred to a crystallization kettle, and placed in a 200°C oven for 8 hours, then cooled to room temperature, washed with ethanol for 6 times, and dried at 60°C to obtain magnetic microspheres. Then take 0.20g and use 100mL 0.1M hydrochloric acid to sonicate, then wash 3 times with water, then ultrasonically disperse into the mixed system of 160mL ethanol, 37mL water and 5mL ammonia water (25%), add 0.36mL tetraethyl orthosilicate and 0.04mLγ -Aminopropyltriethoxysilane (V 硅烷化试剂 / (V 硅烷化试剂 +V 正硅酸 乙酯)=10%), reacted for 6h, and magnetically separated and washed several times to obtain magnetic / aminated silica composite microspheres. Add 1.60mL glutaraldehyde solution to 0.10g magnetic / aminated silica composite microspheres to activate for 2h, recover by magnetic separation and wash with deionized water for several times, then add 1.20mL penicillin acylase at a cer...

Embodiment 2

[0022] 5.40g FeCl 3 ·6H 2 O, 200mL of ethylene glycol and 14.40g of sodium acetate were stirred evenly, then transferred to a crystallization kettle, and placed in a 200°C oven for 8 hours, then cooled to room temperature, washed with ethanol for 6 times, and dried at 60°C to obtain magnetic microspheres. Then take 0.20g and use 100mL 0.1M hydrochloric acid to sonicate, then wash 3 times with water, then ultrasonically disperse into the mixed system of 160mL ethanol, 37mL water and 5mL ammonia water (25%), add 0.36mL tetraethyl orthosilicate and 0.04mLγ -Aminopropyltriethoxysilane (V 硅烷化试剂 / (V 硅烷化试剂 +V 正硅酸 乙酯 )=10%), reacted for 6h, and magnetically separated and washed several times to obtain magnetic / aminated silica composite microspheres. Add 1.20mL of a certain concentration of penicillin acylase diluent to 0.10g of magnetic / aminated silica composite microspheres, vibrate and fix in a water bath shaker at 30°C for 24h, magnetically separate and wash with phosphate buf...

Embodiment 3

[0024] Same as Example 1, keep other conditions constant, change the adding volume of ethyl orthosilicate and γ-aminopropyltriethoxysilane into 0.20mL and 0.20mL respectively in the composite microsphere preparation process, i.e. V 硅烷化试剂 / (V 硅 烷化试剂 +V 正硅酸乙酯 ) = 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com