Preparation method of superparamagnetic ferric oxide nanomaterial

A ferric tetroxide and superparamagnetic technology, applied in the directions of iron oxide/iron hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of complex synthesis method, high cost and the like, achieve simple preparation method, high yield, Mild effect of preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

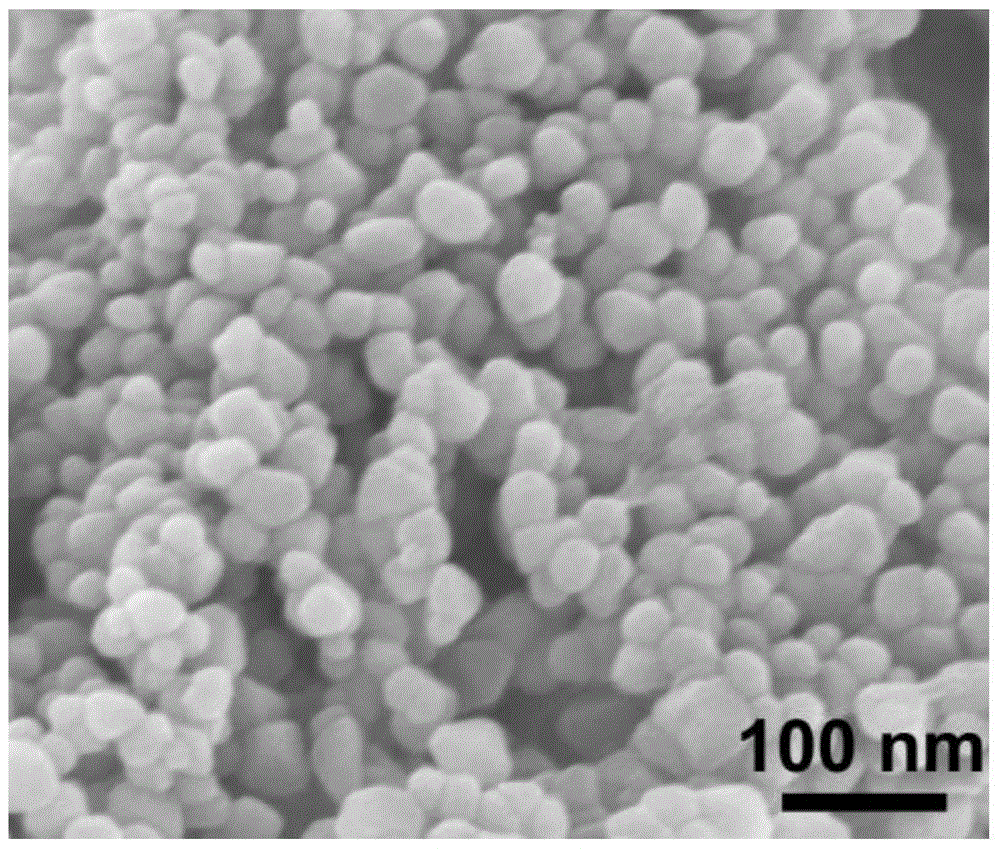

[0031] A kind of preparation method of superparamagnetic ferroferric oxide nanometer material, it comprises the following steps:

[0032] Step 1, the double-distilled water used for configuring the ferrous sulfate solution is first boiled to drive away the air, and the flask used for the reaction is ventilated with nitrogen for five minutes to drive away the air, so as to prevent the ferrous ions from being oxidized during the heating process of step 2; this embodiment In, the molar concentration of ferrous sulfate aqueous solution is 0.1mol / L, and the total volume is 15mL;

[0033] Step 2: Add 0.424g of lithium nitrate and sodium tungstate in an equimolar amount to ferrous sulfate, and heat at .65°C until completely dissolved to obtain a mixed solution. In the present embodiment, the molar concentration of lithium nitrate is 4.1mol / L;

[0034] Step 3, take out 1.5mL of the above solution and place it in a 25mL Teflon liner, add 100 μL of ammonia water, put the Teflon liner i...

Embodiment 2

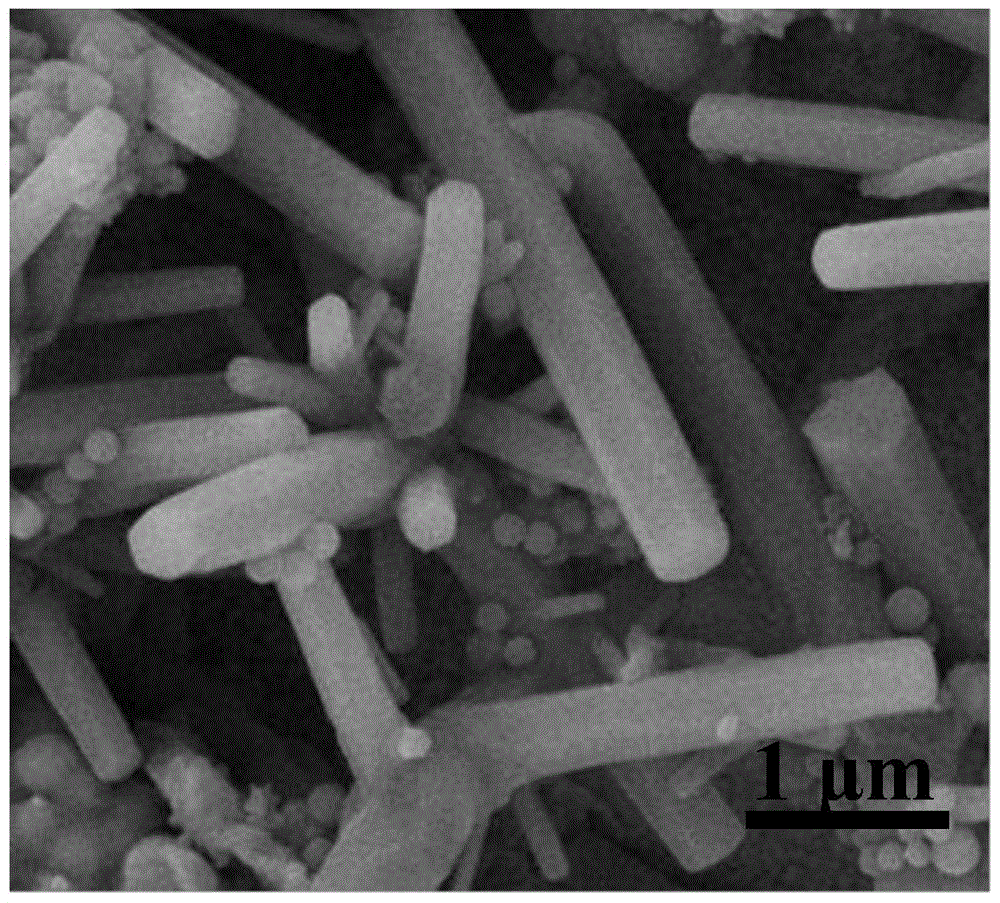

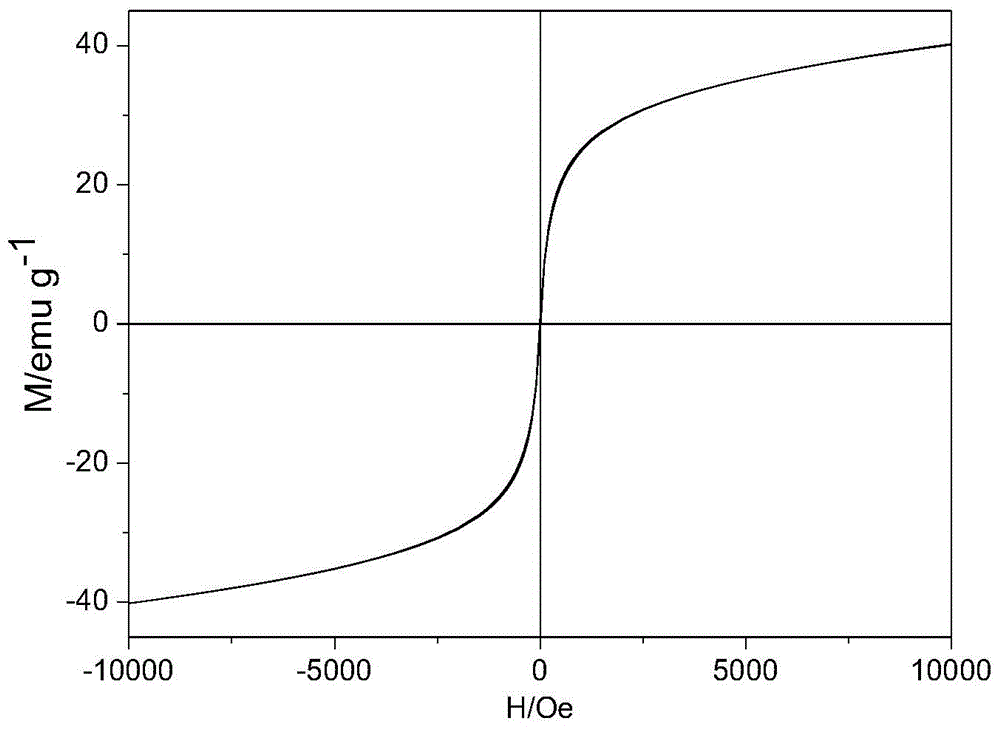

[0038] Embodiment 2, with embodiment 1, wherein the concentration of ferrous sulfate and sodium tungstate is changed into 0.4mol / L, by figure 2 It can be seen that the Fe3O4 nanocrystals obtained at higher concentrations further grow into nanorods. pass Figure 4 It can be seen that as the nanocrystal grows, the superparamagnetism disappears, the maximum saturation magnetic flux drops to 6.94emu / g, the residual magnetization is 2.25emu / g, and the coercive force is 96.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com