Method for preparing environment-friendly plasticizer cyclohexane-1, 2-dicarboxylic acid diethylhexyl ester

A technology of diisooctyl dicarboxylate and environmentally friendly plasticizer, which is applied in the field of chemical engineering, can solve the problems of hygienic performance, non-toxicity and difficulty in meeting environmental protection requirements, and achieve excellent performance, low mobility, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

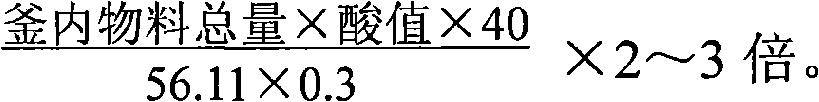

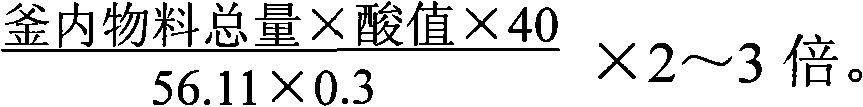

[0016] Cyclohexane-1,2-dicarboxylic anhydride and 2-ethylhexanol molar ratio is 1 / 2.4, total mass is 4720kg cyclohexane-1,2-dicarboxylic anhydride and 2-ethylhexanol are added Heat in the reactor, then add 0.2% tetraisopropyl titanate catalyst relative to the mass of cyclohexane-1,2-dicarboxylic acid anhydride, heat, heat up from 185°C to 220°C, react for 4 hours, dealcoholize, and cool to 85°C Add 80kg of 1.0wt% NaOH aqueous solution at ~90°C to neutralize, wash with water at 90°C to 95°C, and then use steam stripping to refine for 4 hours, add 0.1% of the total amount of active carbon in the kettle to absorb and decolorize for 20 minutes, and press filter to obtain cyclohexane - Diisooctyl 1,2-dicarboxylate, the yield is 97.1%, and the purity is 99.0%.

Embodiment 2

[0018] Cyclohexane-1,2-dicarboxylic acid anhydride and 2-ethylhexanol molar ratio is 1 / 2.5, total mass is 4720kg cyclohexane-1,2-dicarboxylic anhydride and 2-ethylhexanol are added Heating in the reactor, then adding 0.2% tetraisopropyl titanate catalyst relative to the mass of cyclohexane-1,2-dicarboxylic acid anhydride, heating, raising the temperature from 185°C to 220°C for 3.8h, dealcoholization, cooling to 85 Add 75kg of 1.0wt% NaOH aqueous solution at ℃~90℃ for neutralization, wash with water at 90℃~95℃, then steam strip and refine for 4h, add 0.1% activated carbon of the total amount of the kettle material to absorb and decolorize for 20min, and press filter to obtain cyclohexane Diisooctyl alkane-1,2-dicarboxylate has a yield of 98.3% and a purity of 99.1%.

Embodiment 3

[0020] Cyclohexane-1,2-dicarboxylic anhydride and 2-ethylhexanol molar ratio is 1 / 2.6, total mass is 4720kg cyclohexane-1,2-dicarboxylic anhydride and 2-ethylhexanol are added Heating in the reactor, then adding 0.2% tetraisopropyl titanate catalyst relative to the mass of cyclohexane-1,2-dicarboxylic acid anhydride, heating, raising the temperature from 185°C to 220°C for 3.5h, dealcoholization, cooling to 85 Add 75kg of 1.0wt% NaOH aqueous solution at ℃~90℃ for neutralization, wash with water at 90℃~95℃, then steam strip and refine for 4h, add 0.1% activated carbon of the total amount of the kettle material to absorb and decolorize for 20min, and press filter to obtain cyclohexane Diisooctyl alkane-1,2-dicarboxylate has a yield of 98.2% and a purity of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com