Manufacturing method of nano synthetic travertine

A production method and nano-type technology, which is applied in the production field of nano-type synthetic travertine, can solve the problems of artificial synthetic stone surface lack and lack of microporous structure, etc., and achieve the effects of strong implementability, reasonable process, and overcoming heavy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

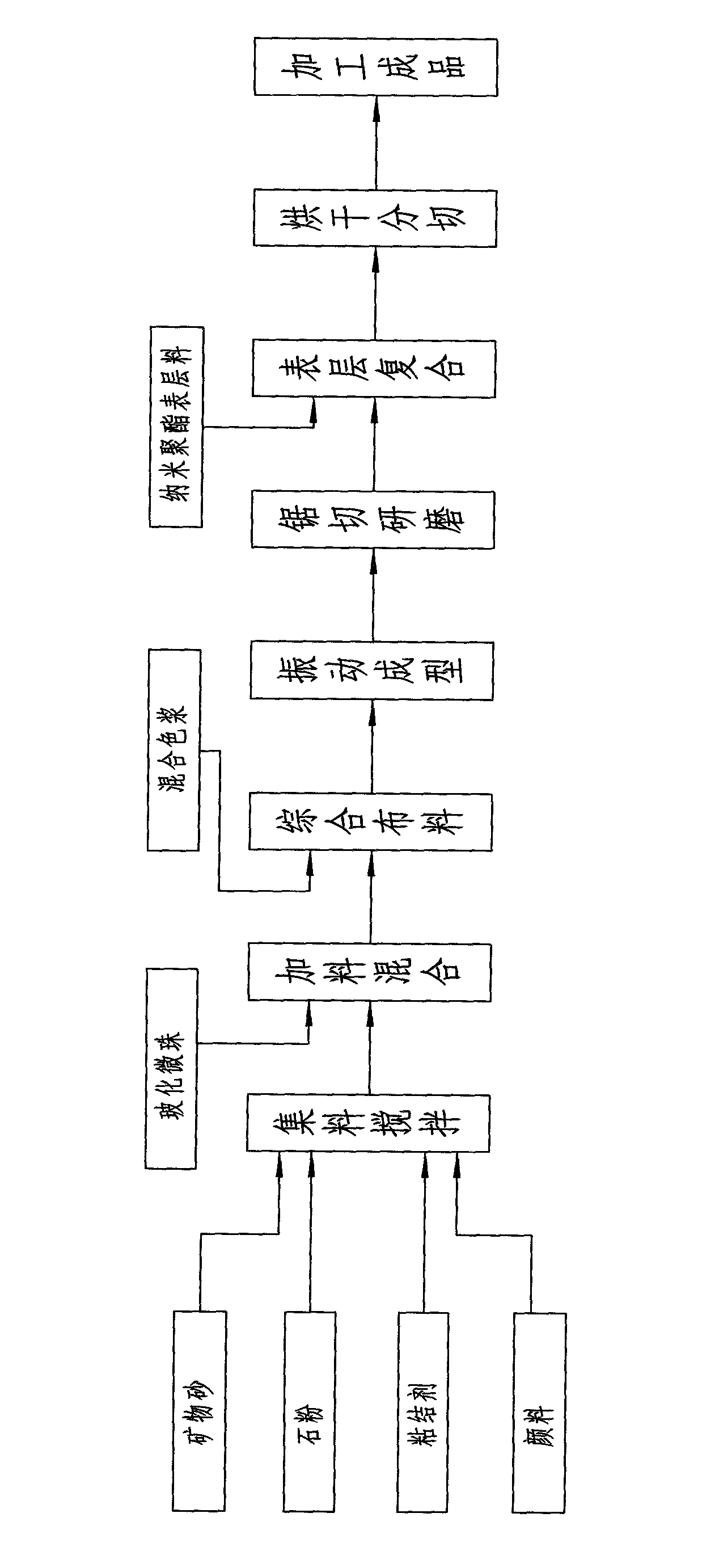

Image

Examples

Embodiment 1

[0022] The production method of nano-type synthetic travertine, the production steps are as follows:

[0023] 1. Aggregate stirring, according to mass percentage, 72% of marble sand of 40-120 mesh, 21% of calcium carbonate powder of 400-1500 mesh, 7% of unsaturated polyester resin, and two kinds of colors are mixed. 0.5% of the total mass of the base material is fully mixed with pigments to obtain a mixed base material;

[0024] 2. Adding materials and mixing, adding light materials with a particle size of 0.1 to 2 mm - vitrified microbeads into the mixed base material, and fully mixing, and the amount of vitrified microbeads added is 4% of the total mass of the mixed base material. microbeads;

[0025] 3. Comprehensive cloth, and at the same time as the cloth, use a spraying device to spray brown mixed color paste on the mixed base material in transmission; in the mixed color paste in step 3, add modified nano powder-modified nano titanium dioxide powder Ti0 2 , and the amo...

Embodiment 2

[0031] The production method of nano-type synthetic travertine, the production steps are as follows:

[0032] 1. Aggregate stirring, 32% of marble particles with 5-100 mesh gradation, 68% of aluminate cement and water, and 0.1% of the total mass of the mixed base material mixed with pigments of various colors are fully Mix to obtain a mixed base material;

[0033] 2. Adding materials and mixing, adding light material with a particle size of 0.1-2mm - vitrified microspheres into the mixed base material, and fully mixing, and the amount of vitrified microspheres added is 10% of the total mass of the mixed base material. microbeads;

[0034] 3. Comprehensive cloth, and at the same time as the cloth, use a spraying device to spray brown mixed color paste on the mixed base material during transmission; the mixed color paste in step 3 is added with modified nano-powder-modified nano-titanium dioxide powder TiO 2 , and the amount of modified nano-titanium dioxide powder added is 2%...

Embodiment 3

[0040] The production method of nano-type synthetic travertine, the production steps are as follows:

[0041] 1. Stir the aggregate, fully mix the quartz stone with gradation of 10-100 mesh, quartz powder with gradation of 400-800 mesh, and unsaturated polyester resin to obtain the mixed base material;

[0042] 2. Adding materials and mixing, adding light materials with a particle size of 0.1 to 2mm - vitrified microbeads into the mixed base material, and fully mixing, and the amount of vitrified microbeads added is 1% of the total mass of the mixed base material. microbeads;

[0043] 3, surface compound: a, according to the method configuration in embodiment 2 nanometer polyester surface layer material, be mixed with modified nanometer powder material and polyester resin by the mass ratio of 10: 100 miscible; Described modified nanometer powder The material is modified nano titanium dioxide powder (TiO 2 ), nano-zinc dioxide powder (ZnO) is prepared according to any mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com