Low-temperature preparation method of super-hydrophobicity film surface

A technology of super-hydrophobicity and manufacturing method, applied in chemical instruments and methods, addition of water-repellent agents, chemical/biochemical treatment of paper, etc., can solve the problems of poor durability of the hydrophobic layer, and achieve good hydrophobic performance, simple operation and low temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

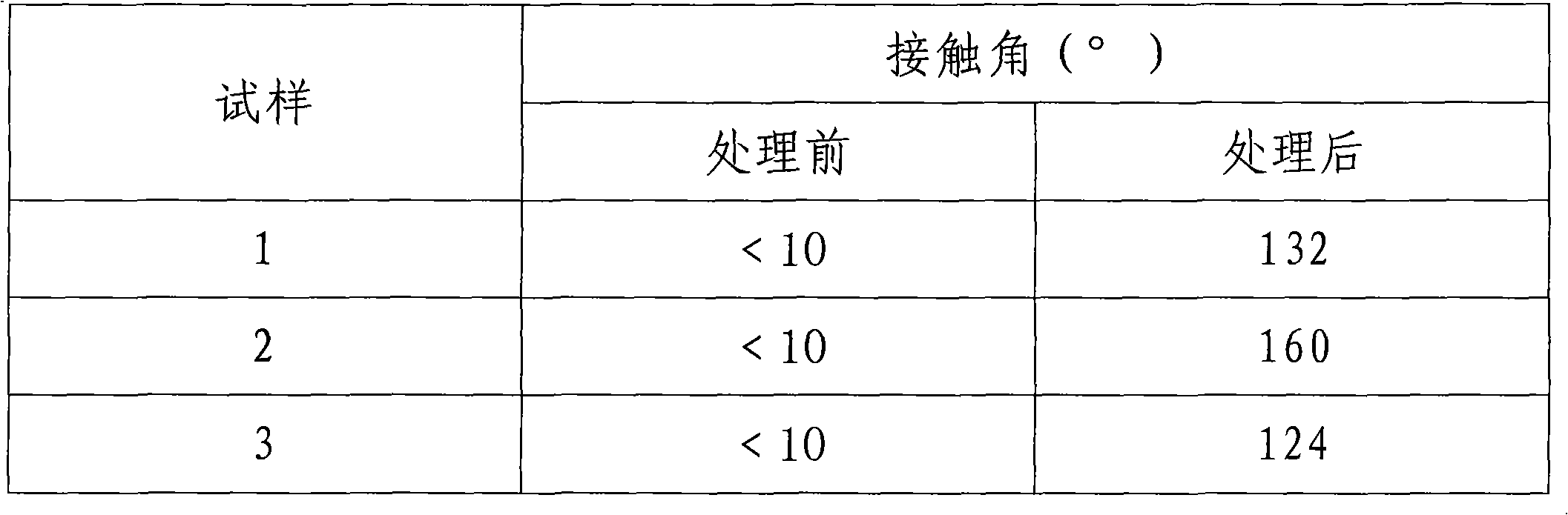

Embodiment 1

[0020] Take ordinary filter paper and carry out UV cleaning and activation treatment by 172nm ultraviolet light at room temperature for 20 minutes; then place the filter paper in the atomized acetic acid environment for 60 seconds; then react with atomized hexadecyltrimethoxysilane , the reaction temperature is 60° C., and the reaction time is 60 minutes. The results are shown in Table 1. The highest static water droplet contact angle of the treated filter paper surface reaches 160°, and the visual color of the filter paper surface has no obvious change.

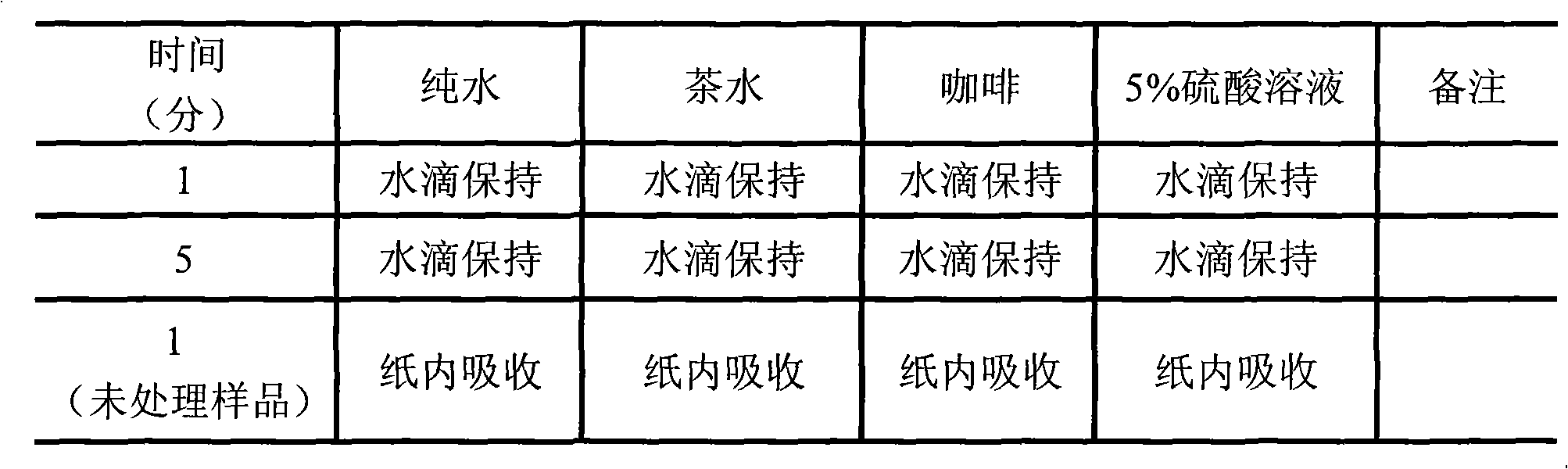

[0021] The above-mentioned filter paper after hydrophobization treatment was placed at the filter port of the suction filtration container, and the experiment of vacuum suction filtration and filtration of oil-water mixture was carried out. The results show that the paper has air permeability; the results of suction filtration of the oil-water mixture show that the water phase can pass through the filter paper under the act...

Embodiment 2

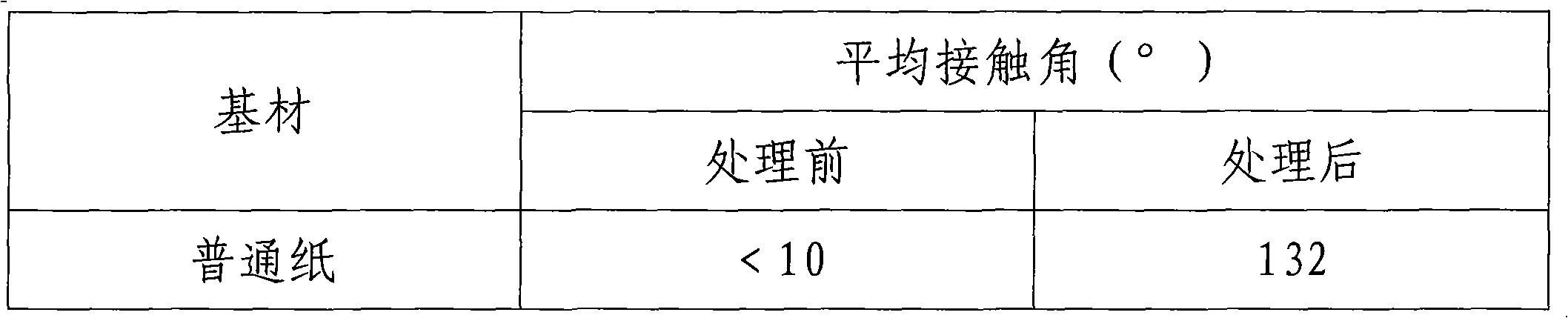

[0028] The same hydrophobic treatment process as in Example 1 was used to treat the surfaces of plain paper, polylactic acid polymer materials, iron sheets, ceramics, glass and frosted glass. The results are shown in Table 3. The treatment method of the present invention can make the surfaces of different substrates hydrophobized at a relatively low temperature, and the contact angle reaches up to 140° at the highest and 106° at the lowest depending on the degree of roughness of the substrate surface.

[0029] table 3

[0030]

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com