Irradiated crosslinking low-smoke halogen-free flame-retardant isolating compound and sheathing compound for solar cables

A technology for solar cables and insulating materials, which is applied to insulated conductors, insulated cables, organic insulators, etc., can solve the problems of lack of resistance to DC voltage under water immersion, and improve the integrity of the coating, improve the pressure resistance of water immersion, and increase the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Each component name and each component parts by weight ratio are:

[0038] EBA 17BA07 (the Lotryl EBA 17BA07 purchased from ARKWMA company) 80kg;

[0039] Maleic anhydride grafted EBA (available from LOTADER 3210 of ARKWMA company) 20kg;

[0040] Magnesium hydroxide 160kg;

[0041] Silane (surface modifier) 0.4kg;

[0042] Grade 1 stearic acid 0.4kg;

[0043] Antioxidant 2kg;

[0044] UV absorber 0.2kg;

[0045] Anti-copper agent 0.1kg;

[0046] Lubricant 2kg;

[0047] Cross-linking sensitizer 2kg.

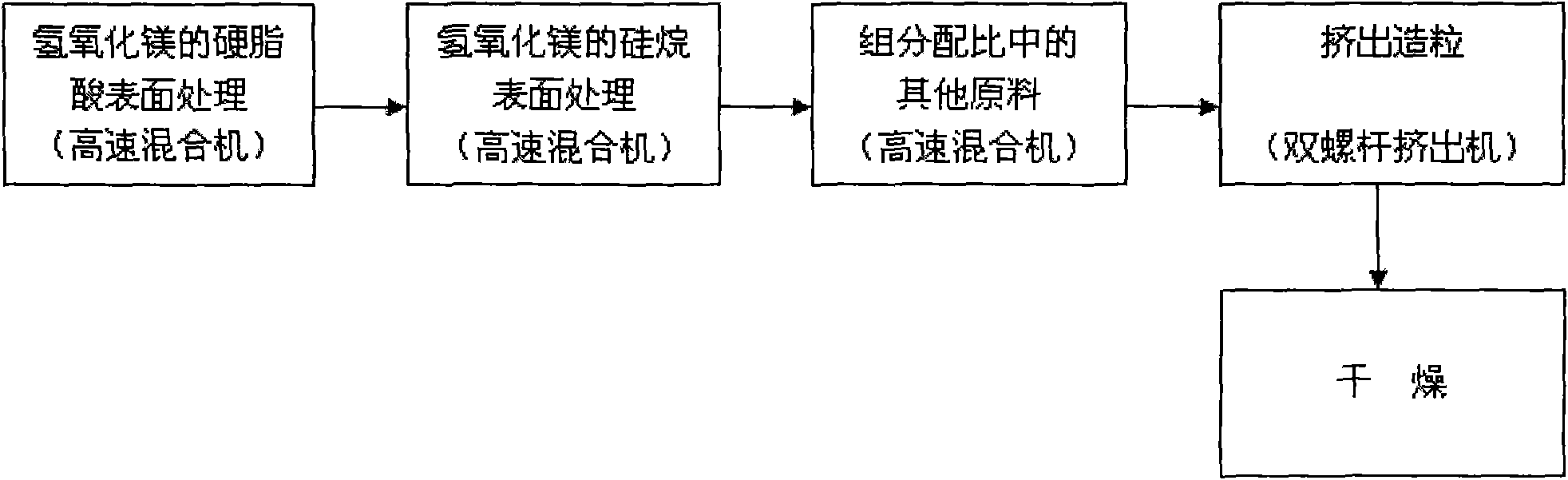

[0048] Preparation method: Stir magnesium hydroxide in a high-speed mixer at high speed and heat up to 100°C, add first-grade stearic acid and stir for 8 minutes, then add acidified silane coupling agent and stir for 5 minutes, and perform secondary coating to improve The integrity of the surface coating of the filler. Then select raw materials according to the parts by weight of the above-mentioned components and drop into other components except magnesium hydro...

Embodiment 2

[0054] Each component name and each component parts by weight ratio are:

[0055] EMA1125 (purchased from EMA1125 of DuPont, USA) 80kg;

[0056] Maleic anhydride grafted EMA (available from LOTADER 3430 of ARKWMA company) 20kg;

[0057] Magnesium hydroxide 160kg;

[0058] Silane (surface modifier) 0.4kg;

[0059] Grade 1 stearic acid 0.4kg;

[0060] Antioxidant 2kg;

[0061] UV absorber 0.2kg;

[0062] Anti-copper agent 0.1kg;

[0063] Lubricant 2kg;

[0064] Cross-linking sensitizer 2kg.

[0065] Preparation method: Stir magnesium hydroxide in a high-speed mixer at high speed and heat up to 100°C, add first-grade stearic acid and stir for 5 minutes, then add acidified silane coupling agent and stir for 8 minutes, and perform secondary coating to improve The integrity of the surface coating of the filler. Then select the raw materials according to the parts by weight of the above-mentioned components and drop into other components except magnesium hydroxide in a high-...

Embodiment 3

[0067] Each component name and each component parts by weight ratio are:

[0068] Ethylene-butyl acrylate copolymer 80kg;

[0069] Functionalized polyolefin resin 20kg;

[0070] Flame retardant 160kg;

[0071] Silane (surface modifier) 0.4kg;

[0072] Grade 1 stearic acid 0.4kg;

[0073] Antioxidant 2kg;

[0074] UV absorber 0.2kg;

[0075] Anti-copper agent 0.1kg;

[0076] Lubricant 2kg;

[0077] Cross-linking sensitizer 2kg.

[0078] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com