Manufacturing technology of automobile asymmetrical universal joint fork based on cold extruding technology and special mould thereof

A universal joint fork and manufacturing process technology, applied in metal extrusion dies and other directions, can solve the problems of low workpiece dimensional accuracy, low material utilization rate, harsh production environment, etc., and achieve good surface quality, high material utilization rate, and machine tool. The effect of less machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] refer to Figure 1 to Figure 6 , a kind of manufacturing process of the automobile asymmetric universal joint fork based on cold extrusion process, described manufacturing process comprises the following steps:

[0028] (1), using cylindrical bar cutting blanking;

[0029] (2) Carry out spheroidizing annealing to the blank to reduce its hardness, then pickling to remove scale, phosphating and saponification lubrication treatment, to obtain a cylindrical blank;

[0030] (3) Forward extrusion and closed shape correction, extruding the cylindrical blank to obtain the required asymmetric shape of the lower half of the universal joint yoke.

[0031] (4) Spheroidizing and annealing the extruded parts obtained by direct extrusion, then pickling to remove scale, phosphating and saponification lubrication treatment;

[0032] (5) Back-extrusion forming: back-extrusion produces a fork shape, and the fork shape of the universal joint fork freely extends upward; the redundant part...

Embodiment 2

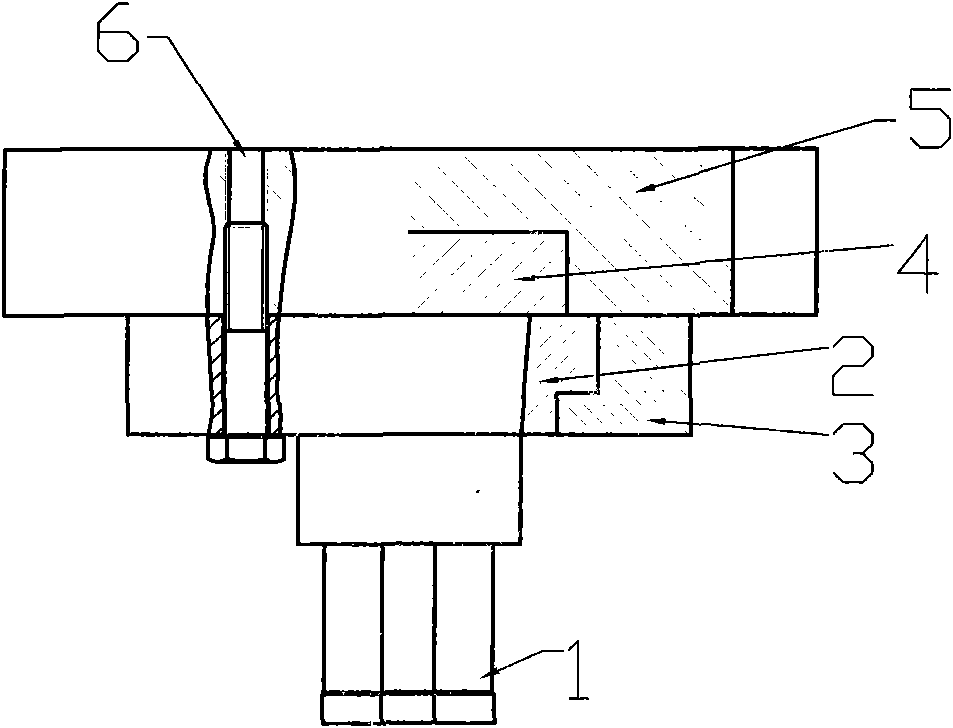

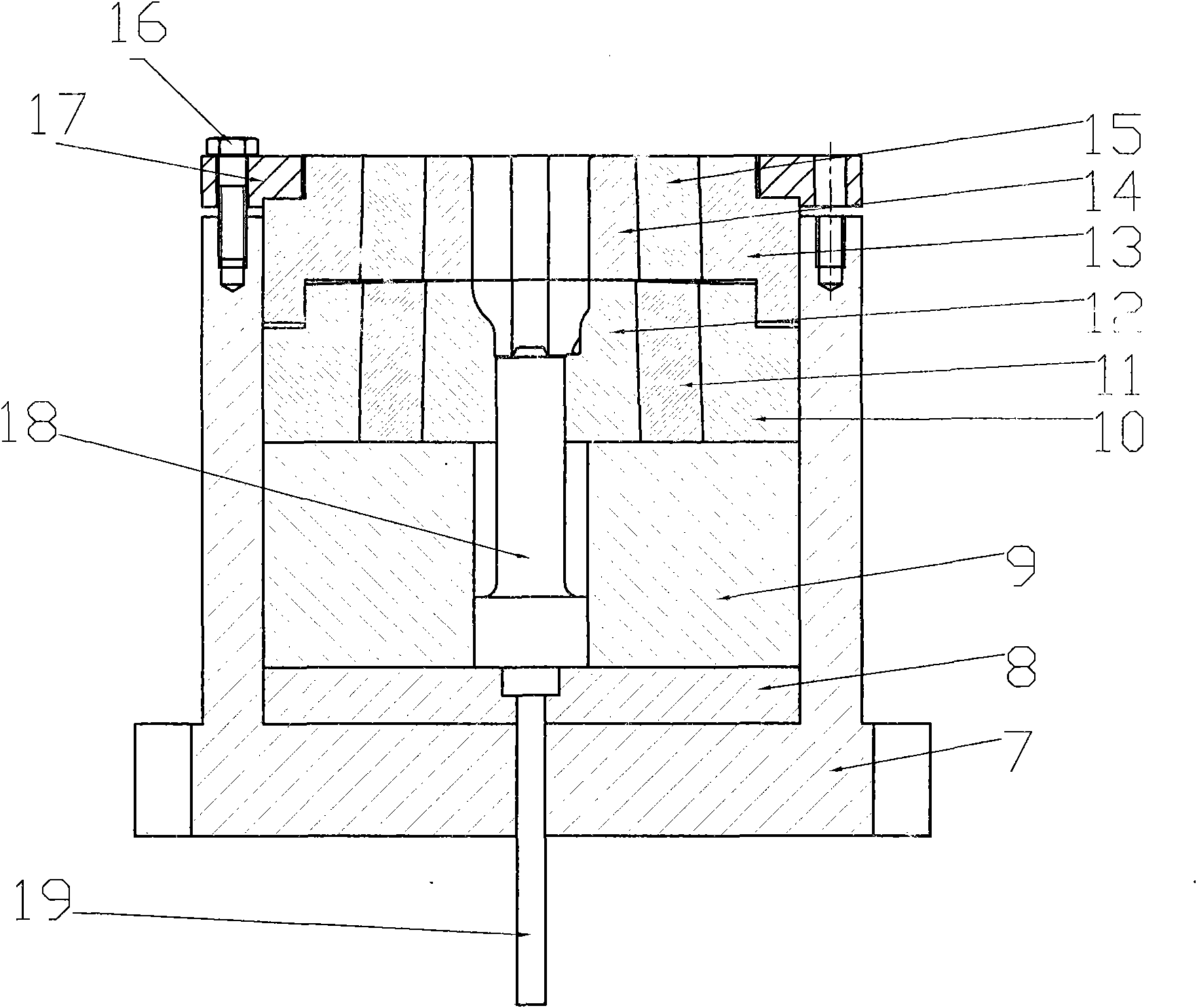

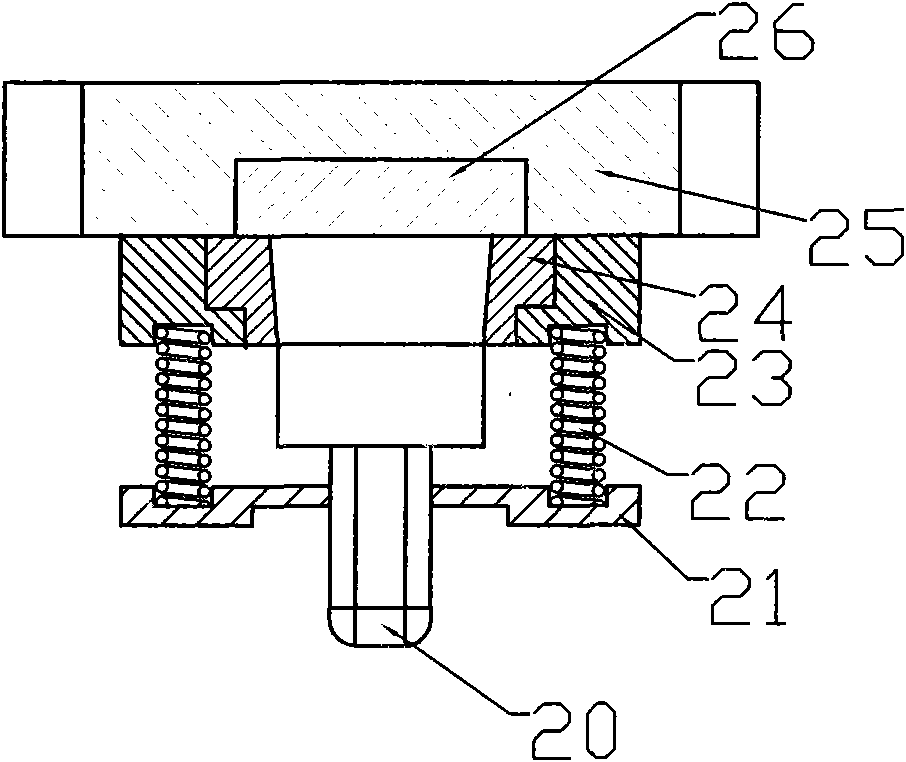

[0036] refer to Figure 1 to Figure 6 , a special mold for the manufacturing process of the asymmetrical universal joint fork of automobiles based on the cold extrusion process, including a forward extrusion mold and a reverse extrusion mold, the forward extrusion mold includes a first upper mold base and a first lower mold base Formwork, the first upper formwork includes a first template 5, a first punch pad 4, a first fixed sleeve 3, a first bushing 2 and a first punch 1, and the first punch 1 passes through The first bushing 2 is fixedly connected with the first fixed sleeve 3, and the first fixed sleeve 3 is fixedly connected with the first template 5, and the first template 5 and the first fixed sleeve 3 are connected with a first A notch, the first punch pad 4 is located in the first notch; the first lower mold frame includes the first pressing plate 17, the first upper die 14, the first lower die 12, the first Backing plate 8, the first support 9, the first mold base 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com