Method for manufacturing aluminum alloy thick plate, and aluminum alloy thick plate

A manufacturing method and technology of aluminum alloy, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of difficult control of surface state and flatness, prone to uneven cross-section and surface, and increased working procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0240] Hereinafter, embodiments of the invention of the present application will be described.

no. 1 example

[0242] This embodiment relates to the first invention. The aluminum alloy used in this example is a 5000 series Al-Mg series alloy.

[0243]The alloys 1A to 12A shown in Table 1 were used as the example alloys, and the alloys 13A to 22A were used as the comparative example alloys.

[0244]

[0245] (deal with)

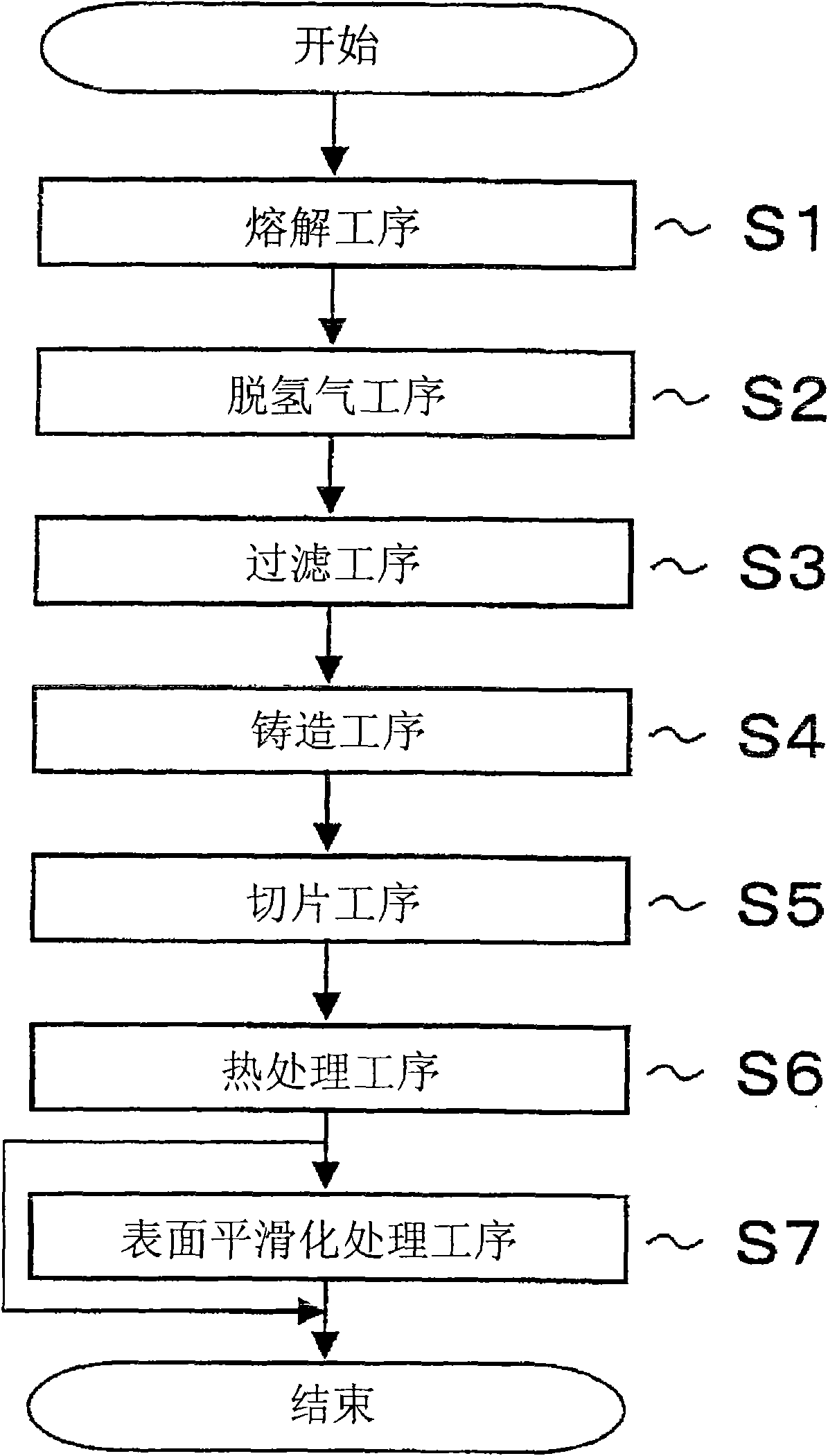

[0246] First, the alloys 1A to 22A are processed in this order in a melting step, a dehydrogenation step, a filtration step, and a casting step to produce an ingot with a plate thickness of 500 mm.

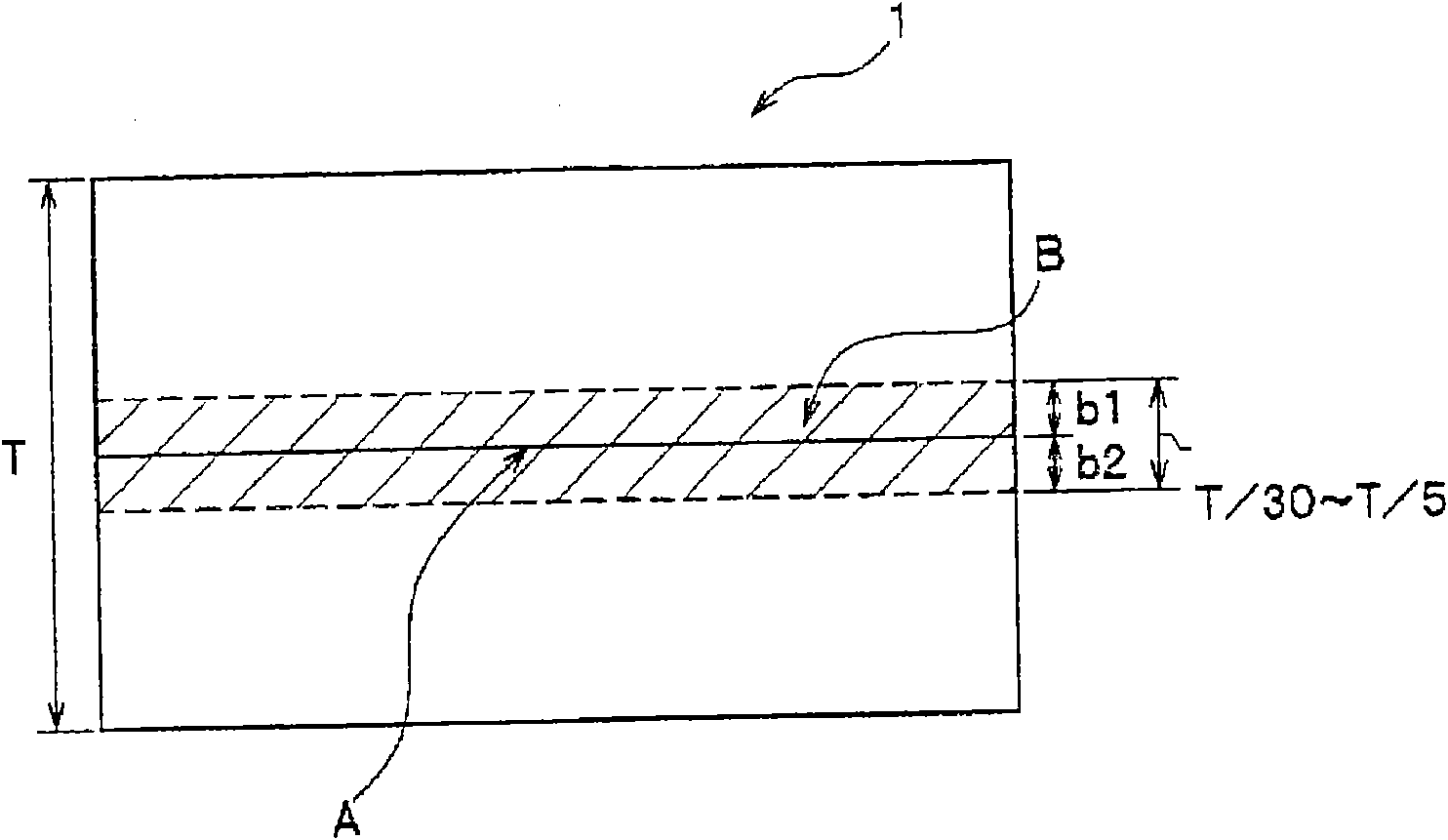

[0247] Next, a sliced material and a hot-rolled material are produced from the ingot. The sliced material is obtained by processing the ingot in a slicing step. The hot-rolled material is obtained by performing hot rolling after heat-treating the ingot. The sliced material and the hot-rolled material are aluminum alloy thick plates with a thickness of 20 mm × a width of 1000 mm × a length of 2000 mm, respectively.

[0248] Then, the sliced material is processed in a ...

no. 3 example

[0291] This embodiment relates to the second invention. The aluminum alloy used in this embodiment is a 3000 series Al-Mn series alloy.

[0292] The alloys 23A and 24A shown in Table 5 were used as the example alloys, and the alloys 25A and 26A were used as the comparative example alloys.

[0293] [table 5]

[0294]

[0295] (deal with)

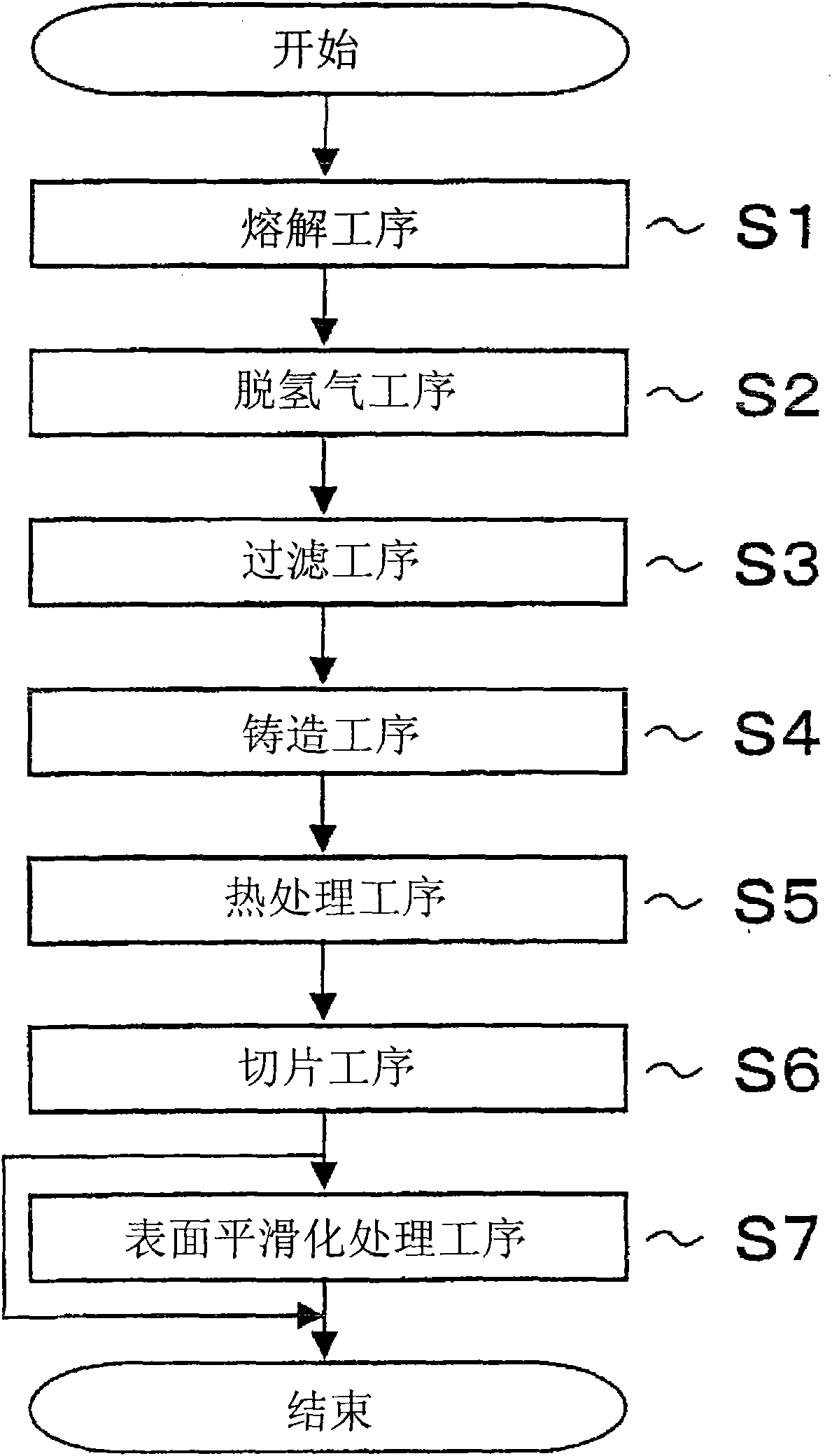

[0296] First, the alloys 23A to 26A are processed in this order in a melting step, a dehydrogenation step, a filtering step, and a casting step to produce an ingot with a plate thickness of 500 mm.

[0297] Next, a sliced material and a hot-rolled material are produced from the ingot. The sliced material is obtained by processing the ingot in a slicing step. The hot-rolled material is obtained by performing hot rolling after heat-treating the ingot. The sliced material and the hot-rolled material are aluminum alloy thick plates with a thickness of 20 mm × a width of 1000 mm × a length of 2000 mm, respectively.

[0298] Then, the sliced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com