Emulsion pump testing system

A test system, emulsion pump technology, applied in pump test, liquid displacement machinery, machine/engine, etc., can solve problems affecting normal operation, huge equipment, increased energy consumption, etc., to achieve wide practicability and energy loss Small, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

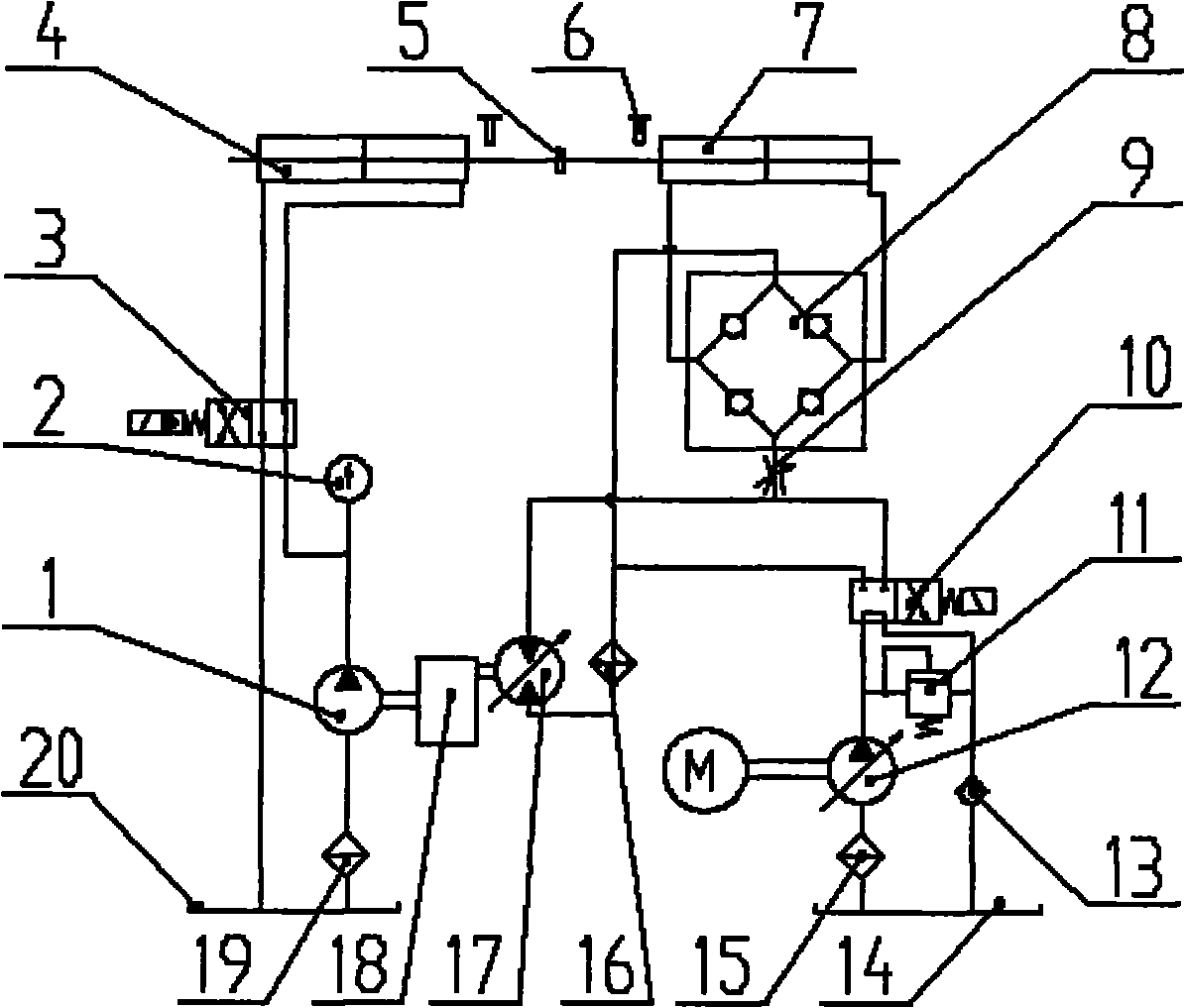

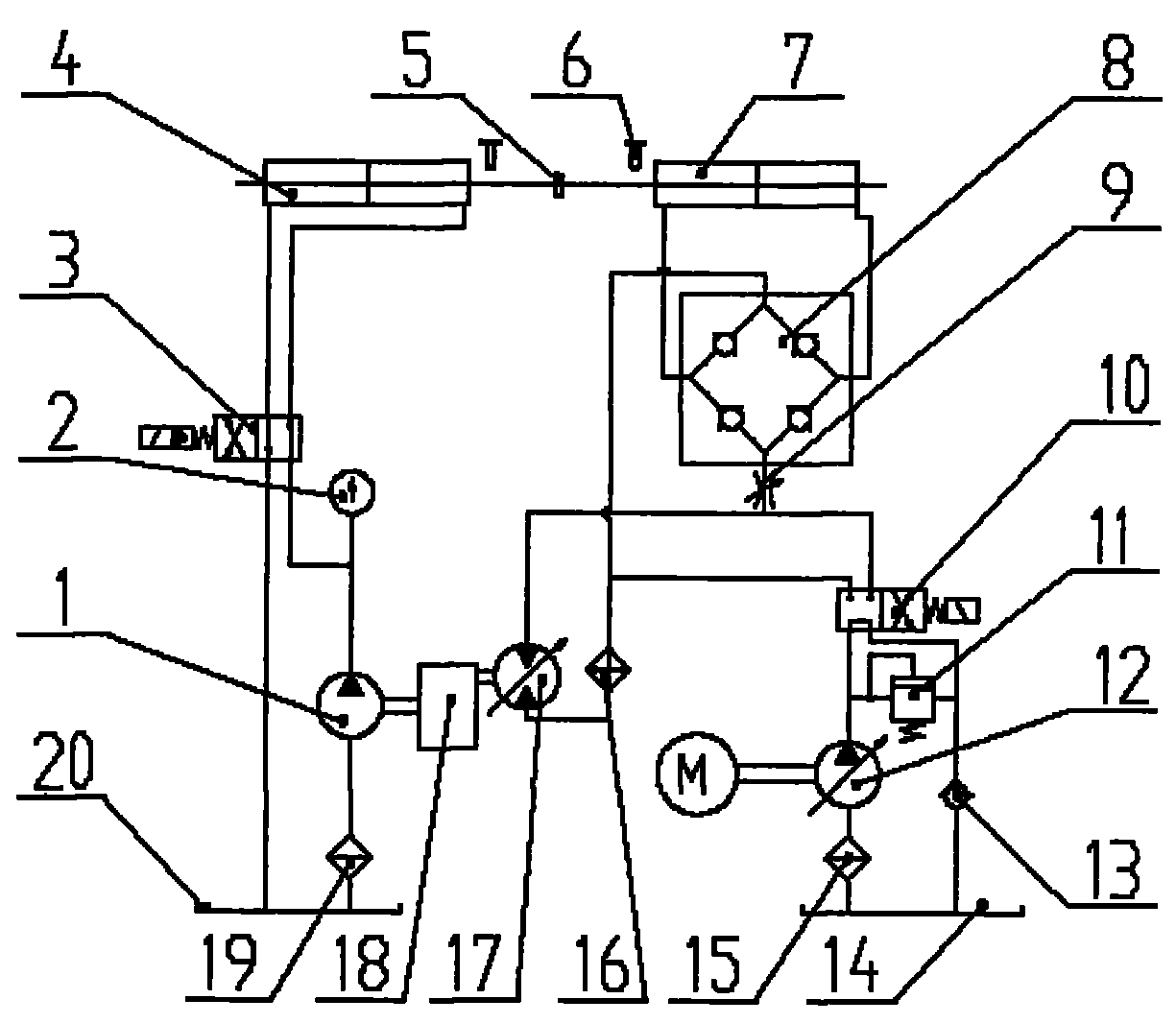

[0010] As shown in the drawings, the emulsion pump test system includes an electrical control system for driving the motor M to open and close, a gearbox 18 for driving the tested pump 1, an emulsion circulation system connected to the tested pump 1 and a hydraulic pressure for driving the gearbox 18. The oil circulation system and the emulsion circulation system mainly include the tested pump oil tank 20 for the tested pump 1 to carry the emulsion, the inlet pipeline of the tested pump 1 is set on the tested pump filter 19, and the tested pump 1 outlet pipeline It is connected with a pressure gauge 2, and is connected with a two-position four-way reversing valve I3 communicated with the oil tank 20 of the pump under test and a loading cylinder I4 whose stroke is controlled by the reversing valve I3; The motor 17, the loading cylinder II7 connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com