Biodegradable shape-memory material based on D,L-polylactic acid and preparation method thereof

A memory material, polylactic acid technology, applied in the field of biomedical polymer materials, can solve the problems of low deformation rate, non-biodegradable, high deformation recovery temperature, etc., and achieve the effect of good biodegradability and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

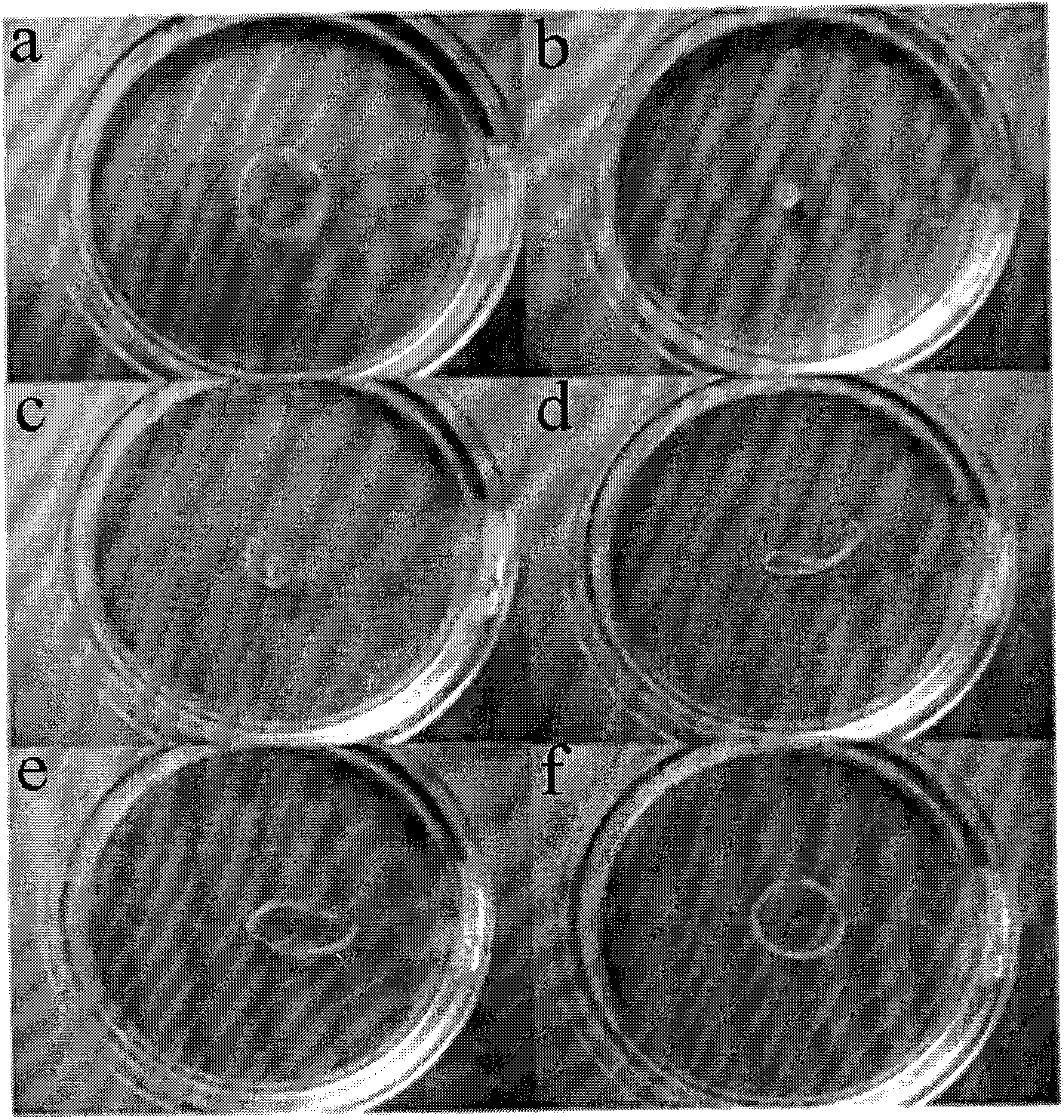

Image

Examples

Embodiment 1

[0021] Example 1: Accurately weigh recrystallized D, L-lactide 14.4g (0.1mol), butanediol 0.887ml (0.01mol) and stannous octoate 0.0083g (2 × 10 -5 mol), mixed evenly, reacted in vacuum, and reacted at 140°C for 24 hours. The reactant was dissolved in chloroform, precipitated with ethanol, and dried in vacuum to constant weight to obtain hydroxyl-terminated D, L-polylactic acid. The molecular weight calculated by proton nuclear magnetic resonance spectrum is 1834, and the glass transition temperature T g = 14.27°C.

Embodiment 2

[0022] Embodiment 2: Accurately weigh recrystallized D, L-lactide 14.4g (0.1mol), butanediol 0.355ml (0.004mol) and stannous octoate 0.0083g (2 × 10 -5 mol), mixed evenly, reacted in vacuum, and reacted at 140°C for 24 hours. The reactant was dissolved in chloroform, precipitated with ethanol, and dried in vacuum to constant weight to obtain hydroxyl-terminated D, L-polylactic acid. The molecular weight calculated by proton nuclear magnetic resonance spectrum is 3720, and the glass transition temperature T g = 36.33°C.

Embodiment 3

[0023] Embodiment 3: Accurately weigh recrystallized D, L-lactide 14.4g (0.1mol), butanediol 0.177ml (0.002mol) and stannous octoate 0.0083g (2 × 10 -5 mol), mixed evenly, reacted in vacuum, and reacted at 140°C for 24 hours. The reactant was dissolved in chloroform, precipitated with ethanol, and dried in vacuum to constant weight to obtain hydroxyl-terminated D, L-polylactic acid. The molecular weight calculated by proton nuclear magnetic resonance spectrum is 7434, and the glass transition temperature T g = 45.02°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com