Synthetic method of porous BaTiO3 nano particle balls

A technology of nanoparticles and synthesis methods, which is applied in the directions of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve the effects of controllable particle size, large specific surface area, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

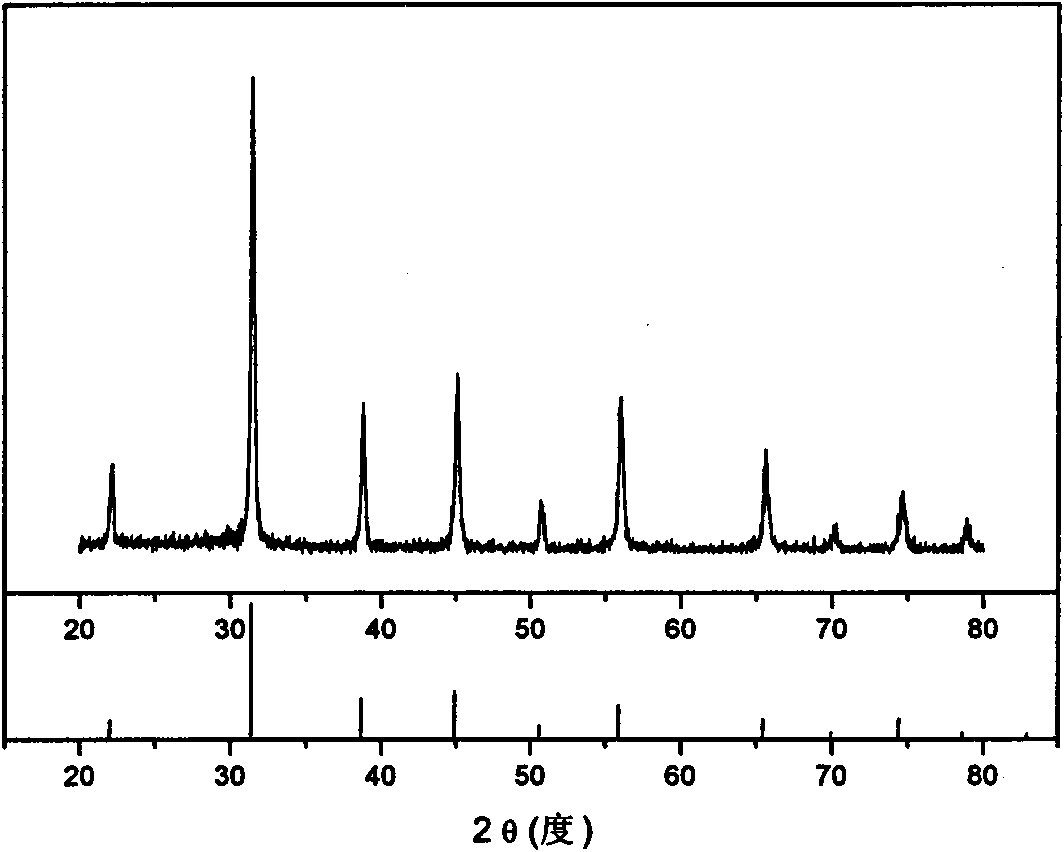

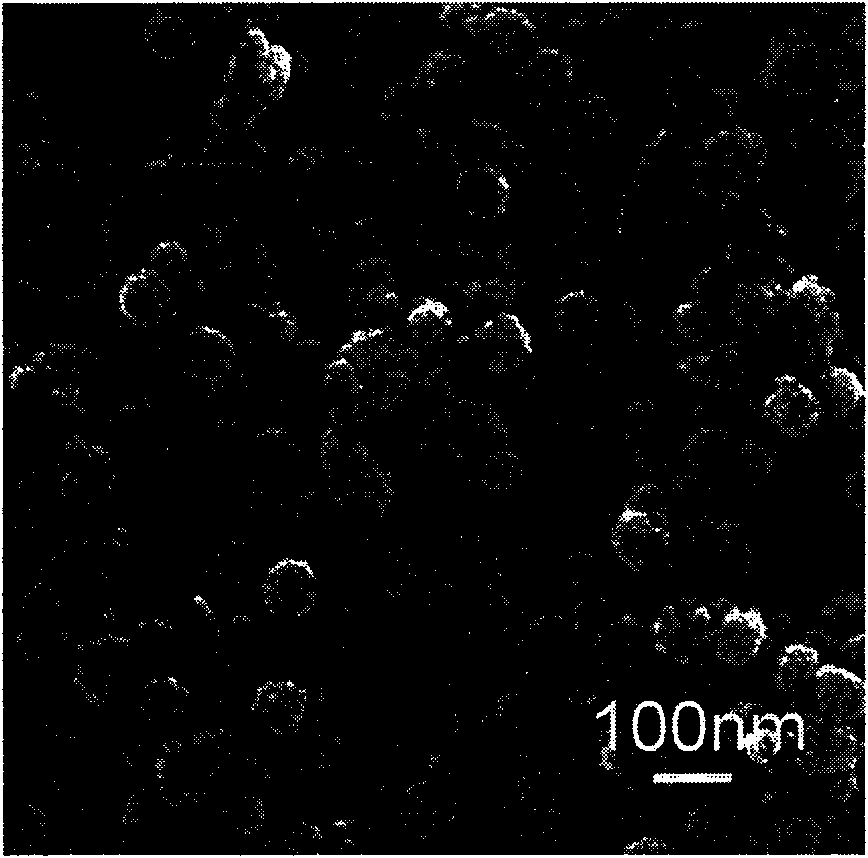

[0018] Slowly drop tetrabutyl titanate into 5ml of ethanol, the molar concentration of tetrabutyl titanate in the mixed solution is 0.01mol / L, stir until the mixture is uniform to form solution A; mix barium chloride and deionized water Stir and mix evenly to form solution B, the concentration of barium chloride in solution B is controlled at 0.01mol / L; solution A and solution B are mixed and stirred evenly, the ratio of the two is controlled at 1:1 (volume ratio), and then add Sodium hydroxide, the concentration of which is controlled at 0.2mol / l, is hydrothermally reacted at a temperature of 100°C for 20 hours to obtain porous BaTiO 3 Nanoparticle balls. The XRD diffraction peaks of the product are as figure 1 As shown in the middle curve, all the diffraction peaks can be compared with the cubic phase BaTio at the bottom 3 Corresponding to the standard peak of the obtained BaTiO 3 The particles have a pure cubic phase structure, and the morphology is as follows figure 2...

Embodiment 2

[0020] Slowly drop tetrabutyl titanate into 5ml of polyethylene glycol (average molecular weight 200), the molar concentration of tetrabutyl titanate in the mixed solution is 1.0mol / L, stir until uniformly mixed, and form solution A; Stir and mix barium chloride and deionized water evenly to form solution B, the concentration of barium chloride in solution B is 1.0mol / L; mix and stir solution A and solution B evenly, the ratio of the two is controlled at 6:1 (volume ratio), then add sodium hydroxide, the concentration is controlled at 2.0mol / l, and the hydrothermal reaction is carried out at a temperature of 200°C for 50h to obtain porous BaTiO 3 Nanoparticle balls. The XRD diffraction peaks of the product are similar to figure 1 As shown in the middle curve, the shape is similar to figure 2 As shown, its BET is greater than 15m 2 / g.

Embodiment 3

[0022] Slowly drop tetrabutyl titanate into 5ml of propanol, the molar concentration of tetrabutyl titanate in the mixed solution is 0.10mol / L, stir until the mixture is uniform to form solution A; mix barium chloride and deionized Stir and mix the water evenly to form solution B, the concentration of barium chloride in solution B is controlled at 0.12mol / L; mix and stir solution A and solution B evenly, the ratio of the two is controlled at 1:6 (volume ratio), and then add Sodium hydroxide, the concentration of which is controlled at 0.5mol / l, is hydrothermally reacted at a temperature of 150°C for 15 hours to obtain porous BaTiO 3 Nanoparticle balls. The XRD diffraction peaks of the product are similar to figure 1 As shown in the middle curve, the shape is similar to figure 2 , whose BET is greater than 15m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com