Experimental method for building forming limit diagram of phase change induced plasticity steel plate

A phase change-induced plasticity and forming limit diagram technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of material waste, time-consuming, labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]The preparation method of TRIP steel plate in the embodiment of the present invention is divided into two kinds: 1, low-carbon low-silicon steel is smelted into steel ingot, composition is to contain C0.18~0.20%, Mn1.30~1.45%, Si0.60~ 0.70%, Al0.50~0.60%, P≤0.009%, S≤0.007%, Nb≤0.040%, and the balance is Fe. After the steel ingot is kept at 1200°C for 1.5 to 2 hours, it is forged into a 30mm thick forging billet. Hot rolled to a thickness of 3.5mm, then cold rolled to a thickness of 1.0mm to obtain a cold-rolled steel plate, the cold-rolled steel plate was kept in a chloride salt at 800°C for 5 minutes, then quenched into a nitrate at a temperature of 400°C for 5 minutes, and air-cooled to room temperature, and prepared into TRIP steel plate. 2. Smelting low-carbon high-manganese steel into steel ingots, the chemical composition of which is C600ppm, Mn23.8%, Si3.0%, Al2.7%, and the balance is Fe. After the steel ingot is kept at 1150°C for 1.5 to 2 hours, it is forged ...

Embodiment 1

[0050] Firstly, the phase transformation induced plastic steel plate is prepared by smelting low-carbon silicon steel into steel ingots, the composition of which is C0.19%, Mn1.32%, Si0.70%, Al0.51%, P0.0068%, S0.0068% by weight %, the balance is Fe. After the steel ingot is kept at 1200°C for 1.5-2hrs, it is forged into a 30mm thick forging billet, hot rolled to a thickness of 3.5mm, and then cold rolled to a thickness of 1.0mm to obtain a cold rolled steel plate, which is then cut into small pieces of reasonable size. Blocks were kept in chloride salt at 800°C for 5 minutes, then quenched into nitrate at 400°C for 5 minutes, and cooled to room temperature in air to prepare TRIP steel plates.

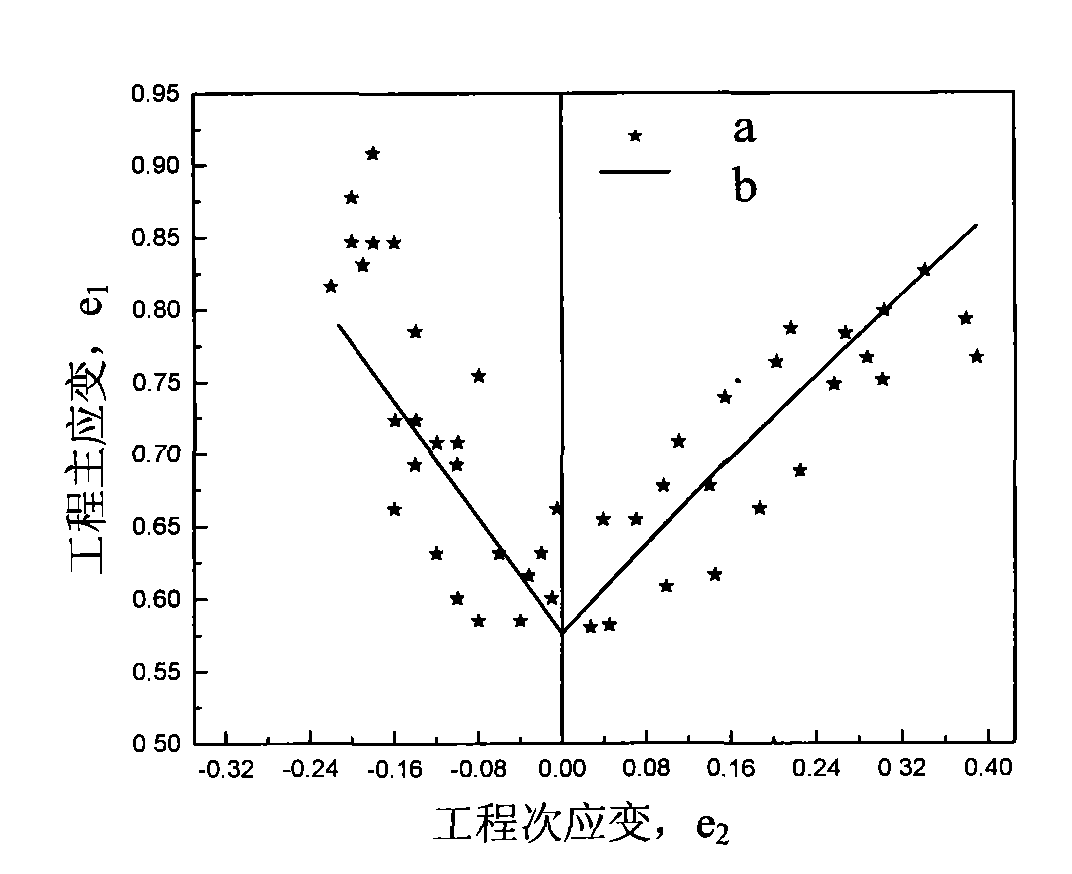

[0051] Measure the strain hardening exponent n of this steel plate to be 0.323, t=1.0mm, calculate FLD according to formula (1) 0 = 0.576. Engineering Principal Strains e for Establishing Forming Limit Diagrams for Phase Transformation-Induced Plastic Steel Sheets 1 with engineering...

Embodiment 2

[0059] Firstly, the phase transformation induced plastic steel plate is prepared by smelting low-carbon silicon steel into steel ingots, and its composition is C0.18%, Mn1.38%, Si0.67%, Al0.56%, P0.0075%, S0.0048% by weight %, Nb0.014%, and the balance is Fe. After the steel ingot is kept at 1200°C for 1.5-2hrs, it is forged into a 30mm thick forging billet, hot rolled to a thickness of 3.5mm, and then cold rolled to a thickness of 1.0mm to obtain a cold rolled steel plate, which is then cut into small pieces of reasonable size. Blocks were kept in chloride salt at 800°C for 5 minutes, then quenched into nitrate at 400°C for 5 minutes, and cooled to room temperature in air to prepare TRIP steel plates.

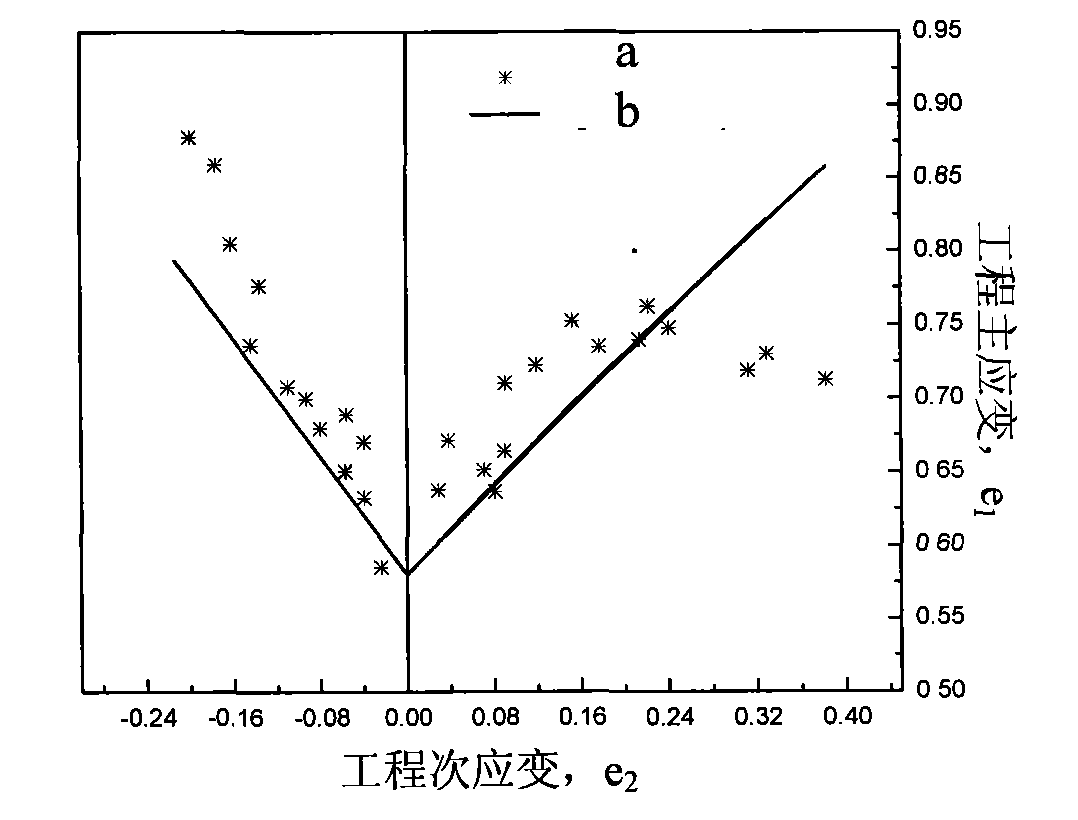

[0060] Measure the strain hardening exponent n of this steel plate to be 0.325, t=1.0mm, calculate FLD according to formula (1) 0 = 0.580. Engineering Principal Strain e established by Forming Limit Diagram of Phase Transformation Induced Plastic Steel Sheet 1 with engineer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strain hardening exponent | aaaaa | aaaaa |

| strain hardening exponent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com