Indium arsenide (InAs) quantum dot material modulated by covering layers of gallium arsenide (GaAs) and gallium antimonide (GaSb) and growing method thereof

A quantum dot material, gallium arsenide technology, applied in the field of indium arsenide quantum dot material and its molecular beam epitaxy growth, can solve the problem of uneven quantum dot size and deterioration of laser gain, and achieve the effect of uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings.

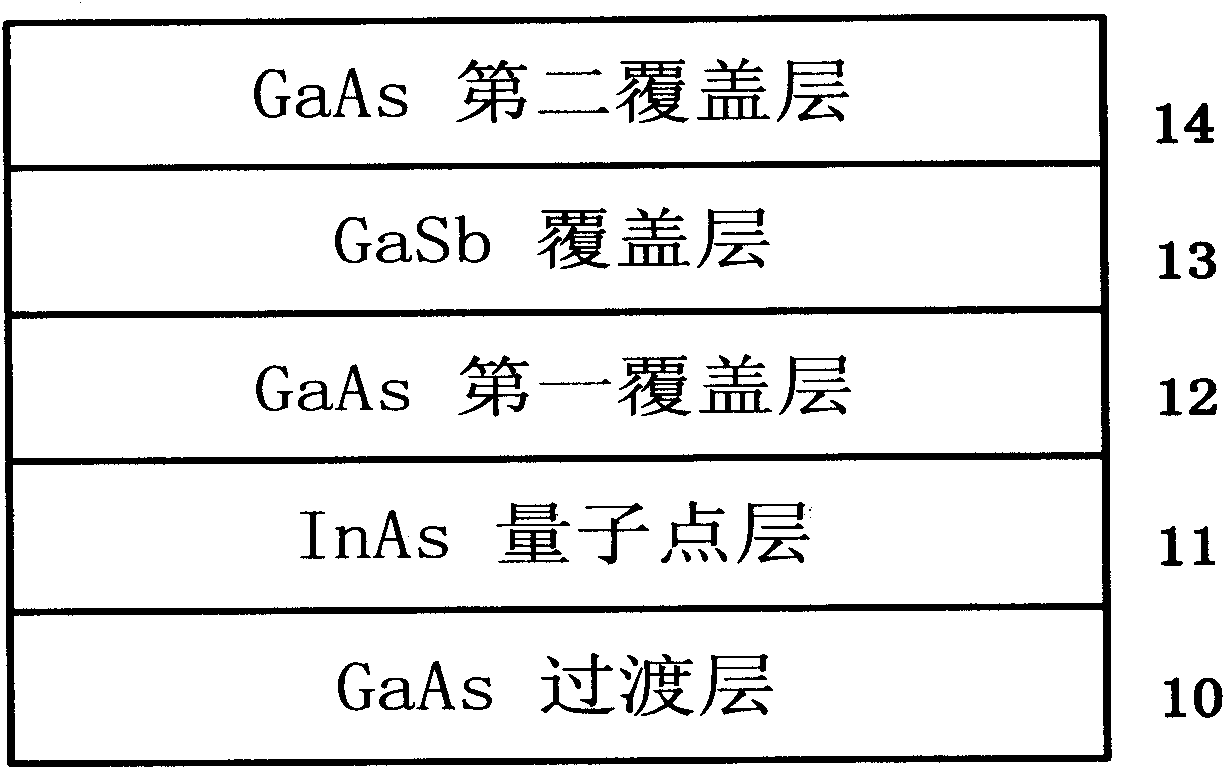

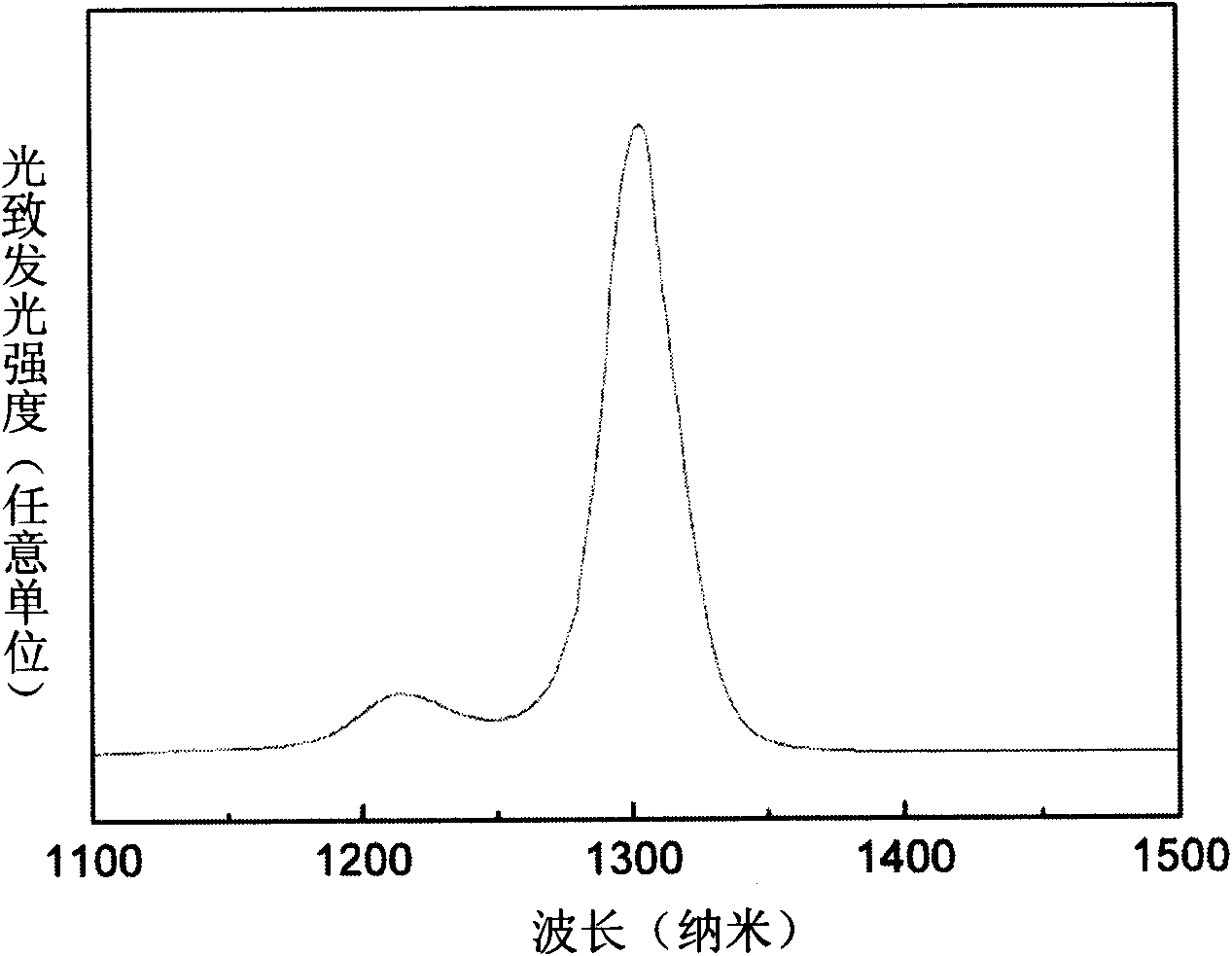

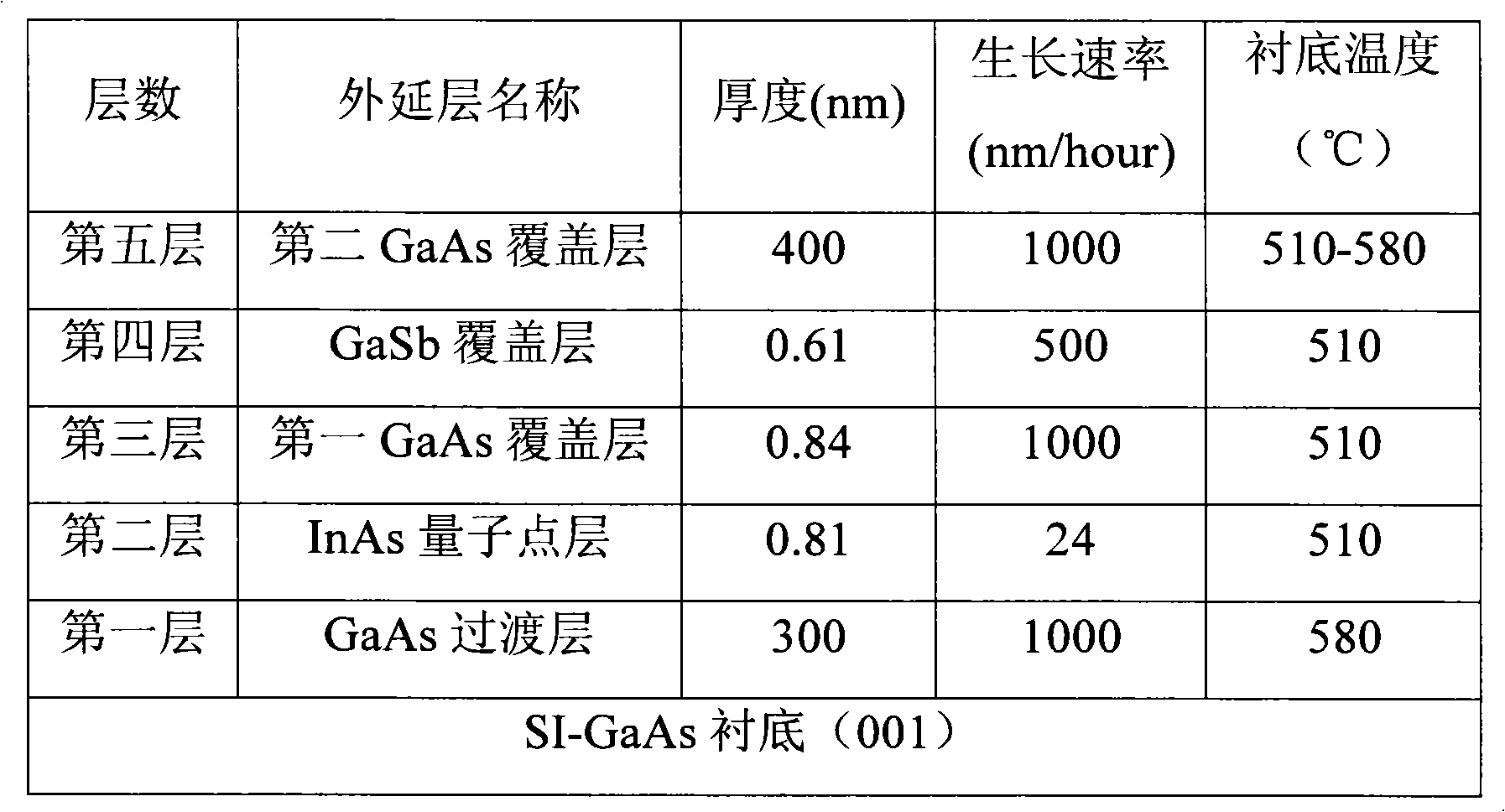

[0027] figure 1 The indium arsenide quantum dot structure modulated by gallium arsenide and gallium antimonide covering layers of the present invention is given. The structure includes a substrate on which a GaAs transition layer 10 is formed by a well-known molecular beam epitaxy method. The substrate temperature is 580°C. , The thickness of the GaAs transition layer is controlled to 500nm. Then, the InAs self-assembled quantum dot layer 11 is grown by molecular beam epitaxy on the GaAs transition layer 10, the substrate temperature is controlled to 510° C., and the thickness is preferably 0.81 nm. Then the substrate temperature was controlled to 510°C, and the first GaAs covering layer 12 was grown by molecular beam epitaxy on the InAs self-assembled quantum dot layer 11, the thickness of the covering layer 12 was 0.84 nm, and GaSb was grown on the coveri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com