Carbon nanotube electron emitter and preparation method thereof

A technology of carbon nanotubes and electron emission, which is applied in the manufacture of electrode systems, manufacture of discharge tubes/lamps, circuits, etc., can solve the problems of not being able to use large areas and limited functions, and achieve good product performance, appropriate arrangement density, and ratio high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

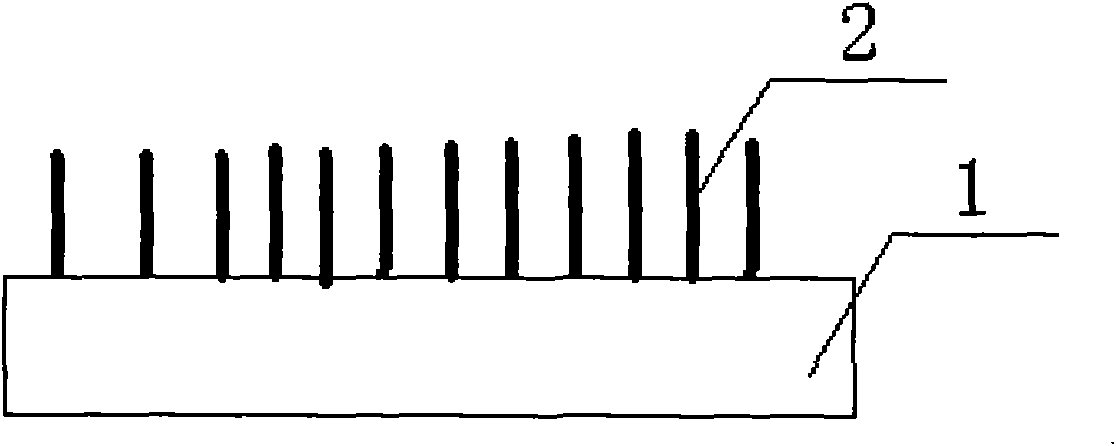

[0018] see figure 1 , a carbon nanotube electron emitter preparation method, the method according to the following steps:

[0019] (1) Prepare carbon nanotube slurry: prepare carbon nanotube slurry with carbon nanotube powder, organic solvent, metal filler and low glass powder with catalyst metal particles attached to one end; the quality of carbon nanotube in the carbon nanotube slurry The fraction is 8%, the mass fraction of metal filler is 5%, the mass fraction of low glass powder is 5%, and the balance is organic solvent; the CNT powder is preliminarily dispersed in the alcohol solution for 4 minutes and then filtered with a 400-mesh sieve. Air-dry the filtrate at room temperature to obtain a preliminary dispersed CNT powder; add isopropanol to the preliminary dispersed carbon nanotubes for ball milling for 0.5h, then add organic solvents, metal fillers and low glass powder in proportion and stir to obtain a preliminary mixture; The preliminary mixture was stirred in a wa...

Embodiment 2

[0030] see figure 1 , a carbon nanotube electron emitter preparation method, the method according to the following steps:

[0031] (1) Prepare carbon nanotube slurry: prepare carbon nanotube slurry with carbon nanotube powder, organic solvent, metal filler and low glass powder with catalyst metal particles attached to one end; the quality of carbon nanotube in the carbon nanotube slurry The fraction is 20%, the mass fraction of metal filler is 12%, the mass fraction of low glass powder is 12%, and the balance is organic solvent; the CNT powder is preliminarily dispersed in the alcohol solution for 6 minutes and then filtered with a 400-mesh screen. Air-dry the filtrate at room temperature to obtain a preliminary dispersed CNT powder; add isopropanol to the preliminary dispersed carbon nanotubes for ball milling for 0.5h, then add organic solvents, metal fillers and low glass powder in proportion and stir to obtain a preliminary mixture; The preliminary mixture was stirred in ...

Embodiment 3

[0042] see figure 1 , a carbon nanotube electron emitter preparation method, the method according to the following steps:

[0043] (1) Prepare carbon nanotube slurry: prepare carbon nanotube slurry with carbon nanotube powder, organic solvent, metal filler and low glass powder with catalyst metal particles attached to one end; the quality of carbon nanotube in the carbon nanotube slurry The fraction is 15%, the mass fraction of metal filler is 8%, the mass fraction of low glass powder is 7%, and the balance is organic solvent; the CNT powder is preliminarily dispersed in the alcohol solution for 5 minutes and then filtered with a 400-mesh sieve. Air-dry the filtrate at room temperature to obtain a preliminary dispersed CNT powder; add isopropanol to the preliminary dispersed carbon nanotubes for ball milling for 0.5h, then add organic solvents, metal fillers and low glass powder in proportion and stir to obtain a preliminary mixture; The preliminary mixture was stirred in a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com