Prestressed steel bar tensioning equipment

A prestressed steel bar and stretching technology, which is applied in the direction of ceramic molding machines and manufacturing tools, to achieve the effect of accurately ensuring the tension displacement, solving the problem of oil cylinder leveling, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention are provided below to help further understanding of the present invention. Those skilled in the art should understand that the descriptions of the embodiments of the present invention are only exemplary, and are not intended to limit the solution of the present invention.

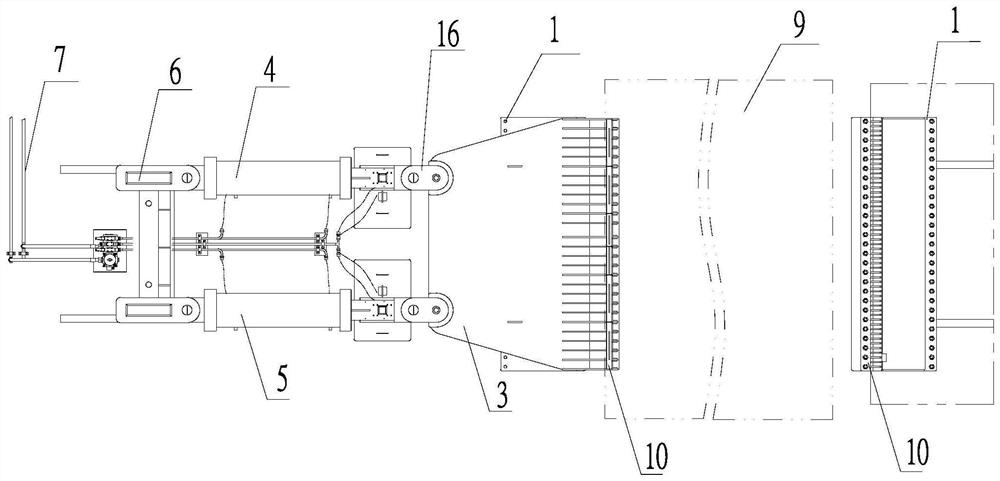

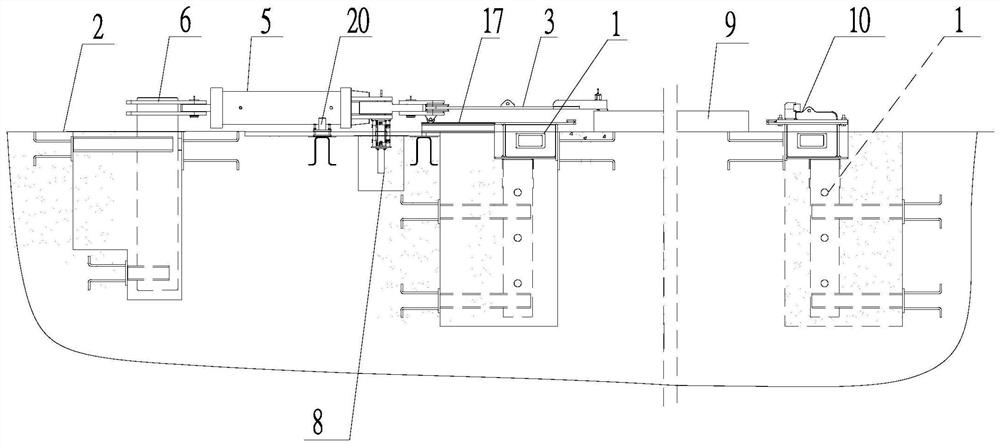

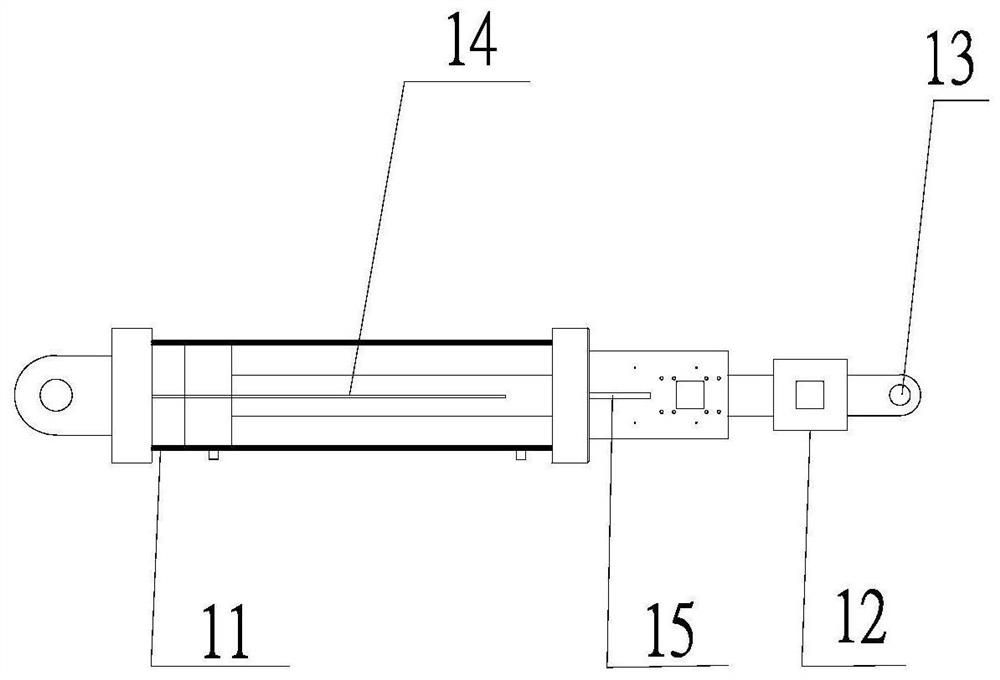

[0039] See attached figure 1 To attach image 3 Schematic, the prestressed steel bar tensioning equipment in an embodiment of the present invention includes a pre-embedded seat 1, an anchor seat, a driving mechanism, a tensioning plate 3 and a synchronous control system. Two pre-embedded seats 1 are respectively embedded in the Underground on both sides of the table form 9, two anchor seats are respectively fixed on the two pre-embedded seats 1, the tension plate 3 includes a first end and a second end, and the driving mechanism includes a driving station and a first telescopic member arranged in parallel , the second telescopic part, the driver is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com