Water cooling radiator

A water-cooled radiator and heat-dissipating core technology, applied in the direction of heat exchanger type, indirect heat exchanger, lighting and heating equipment, etc., can solve the problem of short distance of water flow, poor cooling effect, and short time passing through the cooling area. and other problems to achieve the effect of improving the cooling effect, improving the cooling effect and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

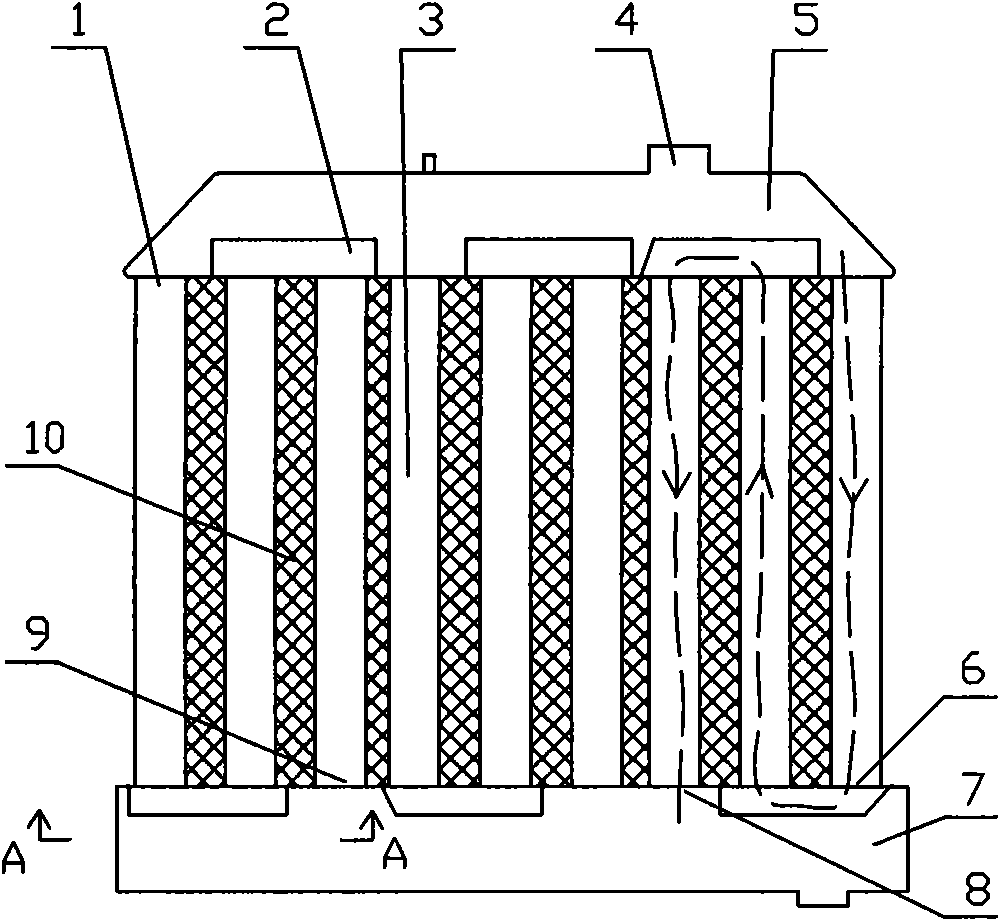

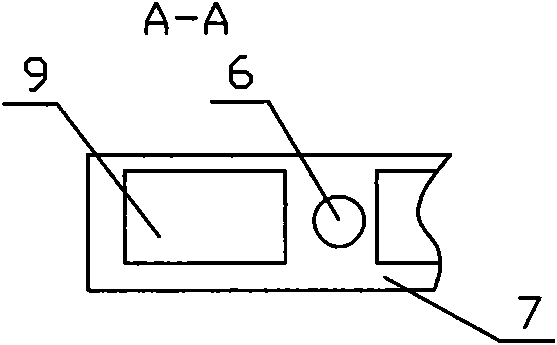

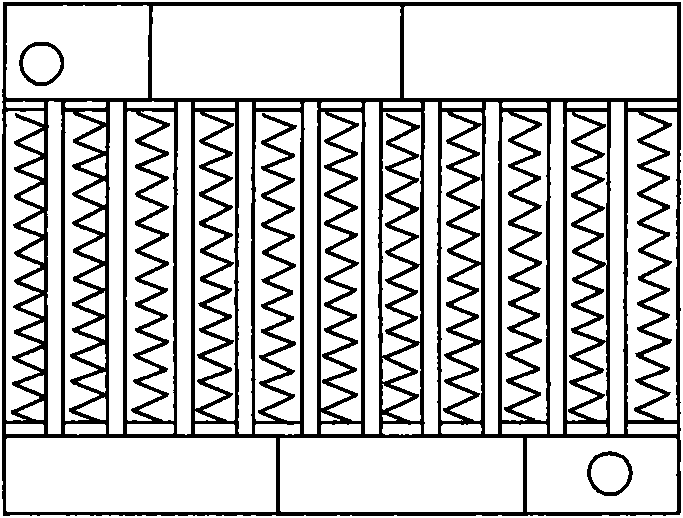

[0013] like figure 1 , 2 As shown, the present invention includes an upper water chamber 5, a lower water chamber 7, a plurality of pipes 3 and a heat dissipation core, a pipe that is arranged in a rotary shape is provided between the upper and lower water chambers, and a rotating pipe is arranged between the upper and lower water chambers. The rotary pipeline 3 is connected.

[0014] It also includes compartments 2 arranged in the upper and lower water chambers to communicate with the nozzles of adjacent pipes.

[0015] The pipeline 3 that is revolving shape is made of 3 or 5 or 7 pipelines or multiples thereof. Each connected revolving pipe 3 has a revolving pipe inlet 1 located in the upper water chamber 5 and a revolving pipe outlet 9 located in the lower water chamber 7, and the compartment 2 is sealed and communicated with adjacent pipes located in the upper water chamber 5 and the lower water chamber 4 The entrance and exit, that is, the rotary port 6 that forms the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com