Steel wire boronation and drying device

A drying device and steel wire technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of increasing energy consumption, increasing production costs of enterprises, and large power consumption, so as to increase the running distance and save the land area. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

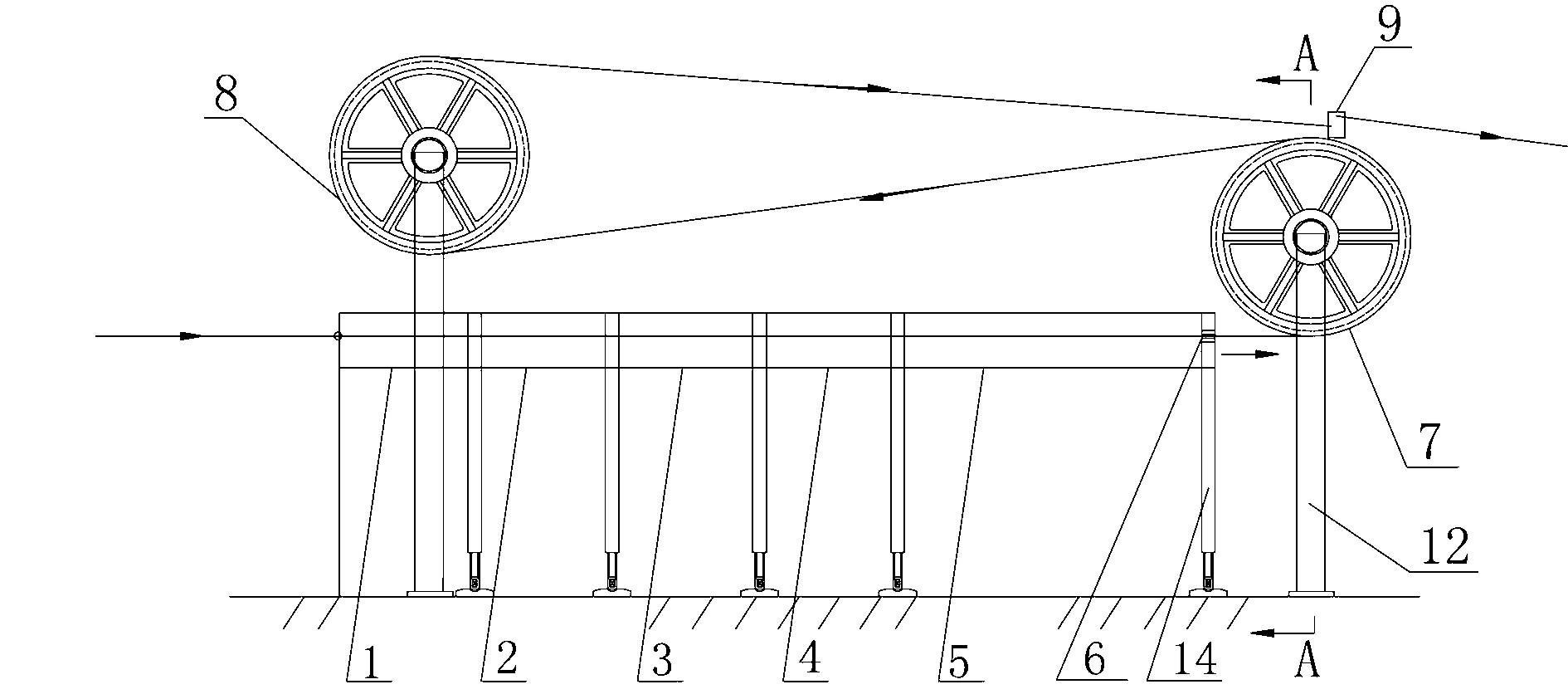

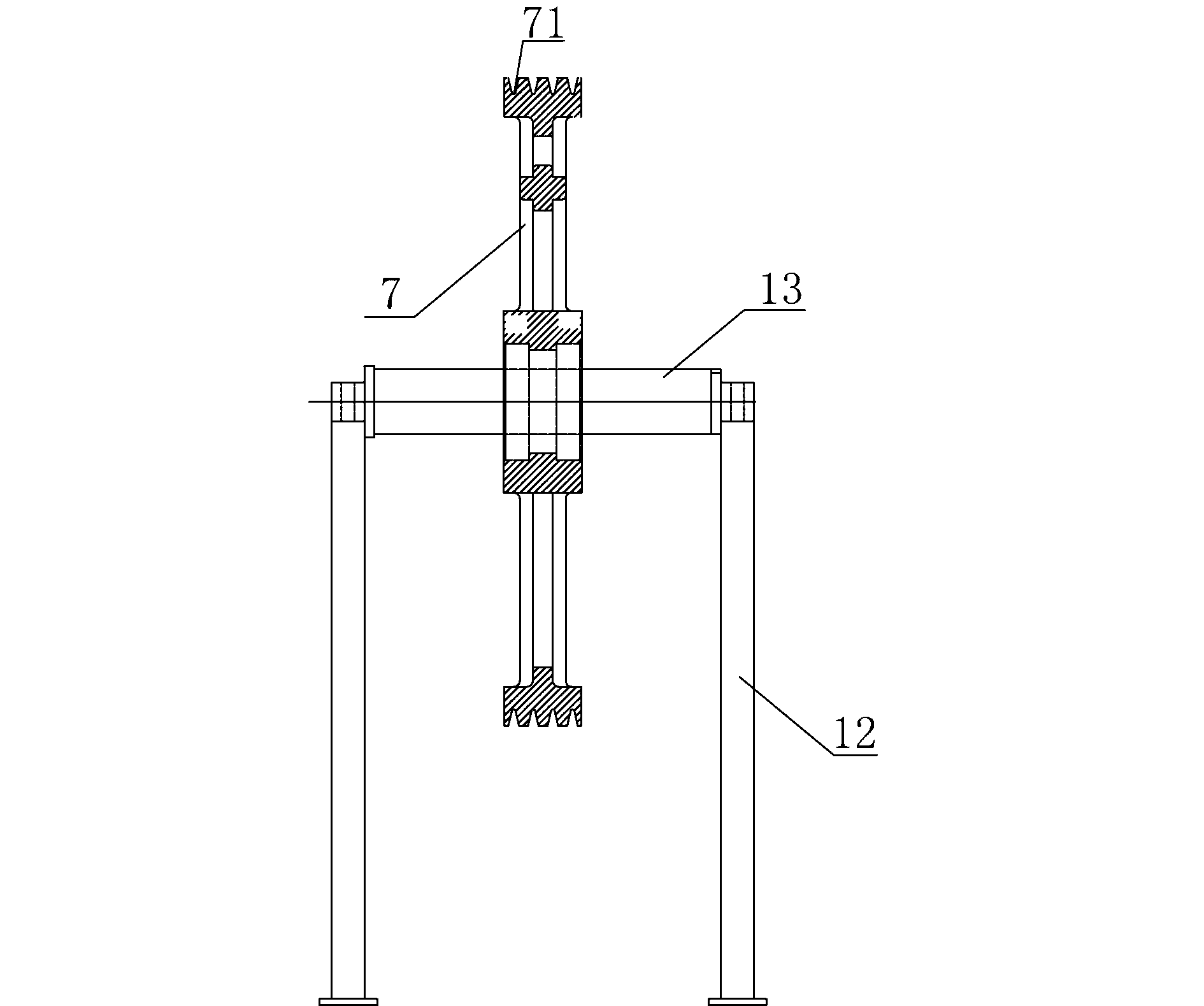

[0010] like figure 1 , figure 2 As shown, the steel wire boriding and drying device of the present invention comprises a strip frame 14, on which a first cold water tank 1 and a pickling tank 2 are sequentially arranged along the running direction of the steel wire on the strip frame 14 , the second cold water tank 3, the hot water tank 4, the boronizing tank 5 and the air nozzle 6, the rear end top of the elongated frame 14 is provided with a first guide wheel 7, and the first guide wheel 7 is installed on the guide shaft 13 through a bearing Above, the two ends of the guide shaft 13 are installed on the bracket 12 through bearings, and the second guide wheel 8 is arranged above the front end of the elongated frame 14. The structure and installation method of the second guide wheel 8 are the same as the first guide wheel 7, No mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com