Method for extracting dioscin

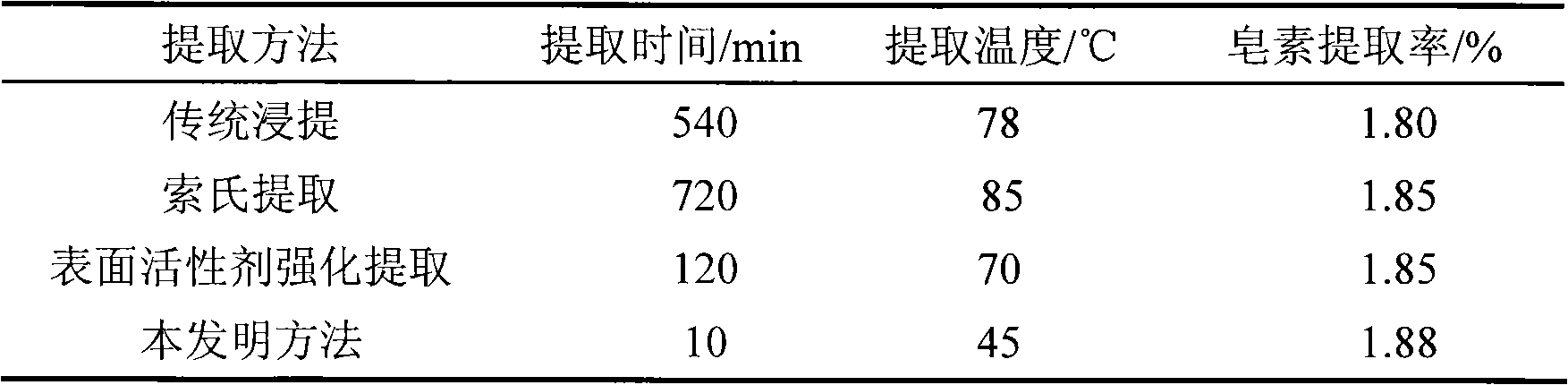

A technology of diosgenin and extraction method, which is applied in the field of extraction of dioscin, can solve the problems of long extraction time (several hours to more than ten hours, not suitable for industrialized large-scale production, large amount of solvent, etc.), shorten the infiltration time, and promote comprehensive Utilization, good social benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method of this embodiment comprises the following steps: wash, dry and crush the rhizome of Dioscorea chinensis to 80 meshes, weigh 5.00 g of dry powder, add an aqueous solution of sodium lauryl sulfate with a mass fraction of 3.0%, and the liquid-solid ratio is The ratio of solvent to dry powder is 8:1, and ultrasonic extraction with a frequency of 20KHz and a power of 60W is used for 20 minutes, and the solid is separated to obtain an extract; HCl is added to the extract and heated and hydrolyzed to obtain crude diosgenin, and the obtained diosgenin is determined The yield was 1.86%.

Embodiment 2

[0023] The method of the present embodiment comprises the following steps: cleaning the rhizome of turmeric, drying, pulverizing to 90 mesh, weighing 5.00g of dry powder, adding a mass fraction of 5.0% sodium dodecylsulfonate aqueous solution, the liquid-solid ratio is 12: 1. Ultrasonic extraction with a frequency of 30KHz and a power of 90W was used for 30 minutes, and the solid was separated to obtain an extract; sulfuric acid was added to the extract and heated for hydrolysis to obtain crude diosgenin, and the yield of the obtained diosgenin was determined to be 1.88%.

Embodiment 3

[0025] The method of this embodiment comprises the following steps: washing, drying, and pulverizing the fine yam rhizomes to 100 meshes, weighing 5.00 g of dry powder, adding a 7.0% aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 7.0%, and the liquid-solid ratio 10:1, ultrasonic extraction with a frequency of 15KHz and a power of 120W for 10 minutes, the solid was separated to obtain an extract; after concentration, ethyl acetate was added to degrease, the concentrated solution was separated, and evaporated to dryness under reduced pressure to obtain 0.21 g of crude diosgenin. Crude diosgenin was hydrolyzed by adding sulfuric acid and heating to obtain crude diosgenin, which was recrystallized to obtain 0.091 g of high-purity diosgenin, and the yield of the obtained diosgenin was determined to be 1.82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com