Method for preparing food grade triacetyl glycerine

A triacetin, food-grade technology, applied in the field of preparation of food-grade triacetin, can solve the problems that can not be further improved, affect product quality, etc., achieve the improvement of heavy metal content, improve quality and stability, and reduce moisture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

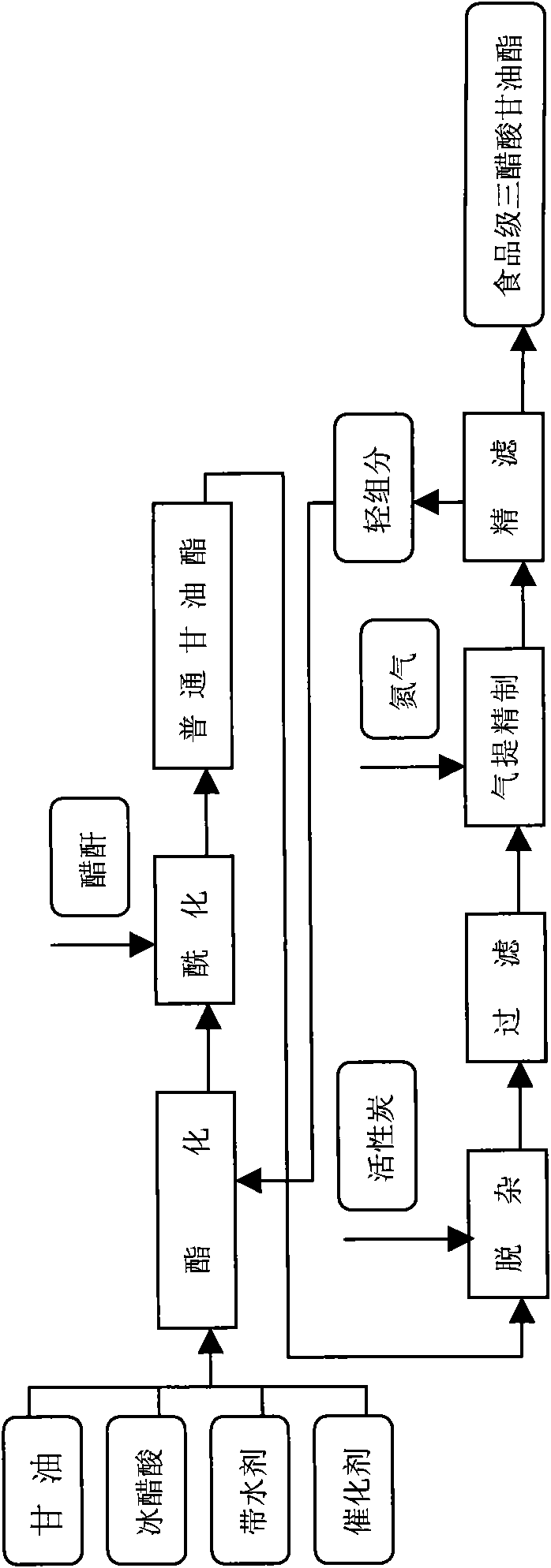

[0016] Such as figure 1 As shown, the esterification reaction adopts rectification technology. Put glycerin, glacial acetic acid, azeotropic dehydrating agent and acid catalyst into the reaction kettle with rectification tower, condenser and water separator to carry out the reaction. In the tower, after the discharge water reaches the theoretical value, the dehydrating agent and unreacted glacial acetic acid are distilled out and returned for recycling. The crude product from the tower kettle is sent to the acylation kettle, and after adding acetic anhydride to react, triacetin is vacuumed Pull out from the kettle to obtain ordinary glycerol triacetate.

[0017] Then put the common triacetin (5000Kg) into a stirred reactor, add 10Kg of activated carbon, and stir at room temperature for 2 to 3 hours. Open the bottom valve of the miscellaneous pot, filter through the plate and frame filter press, and pump the filtrate into the intermediate storage tank. The triacetin after re...

Embodiment 2

[0021] Active carbon add-on is 25kg, and other processing conditions are identical with embodiment 1.

Embodiment 3

[0023] Active carbon add-on is 50Kg, and other process conditions are identical with embodiment 1.

[0024] The products obtained in Examples 1-3 have the following common characteristics: triacetin content of 99.5%, chromaticity below 10, acid value of about 0.005%, water content of less than 0.05%, and heavy metal content of about 5ppm. It can be seen that the product of the present invention has improved quality and stability, and is suitable for use as food-grade triacetin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com