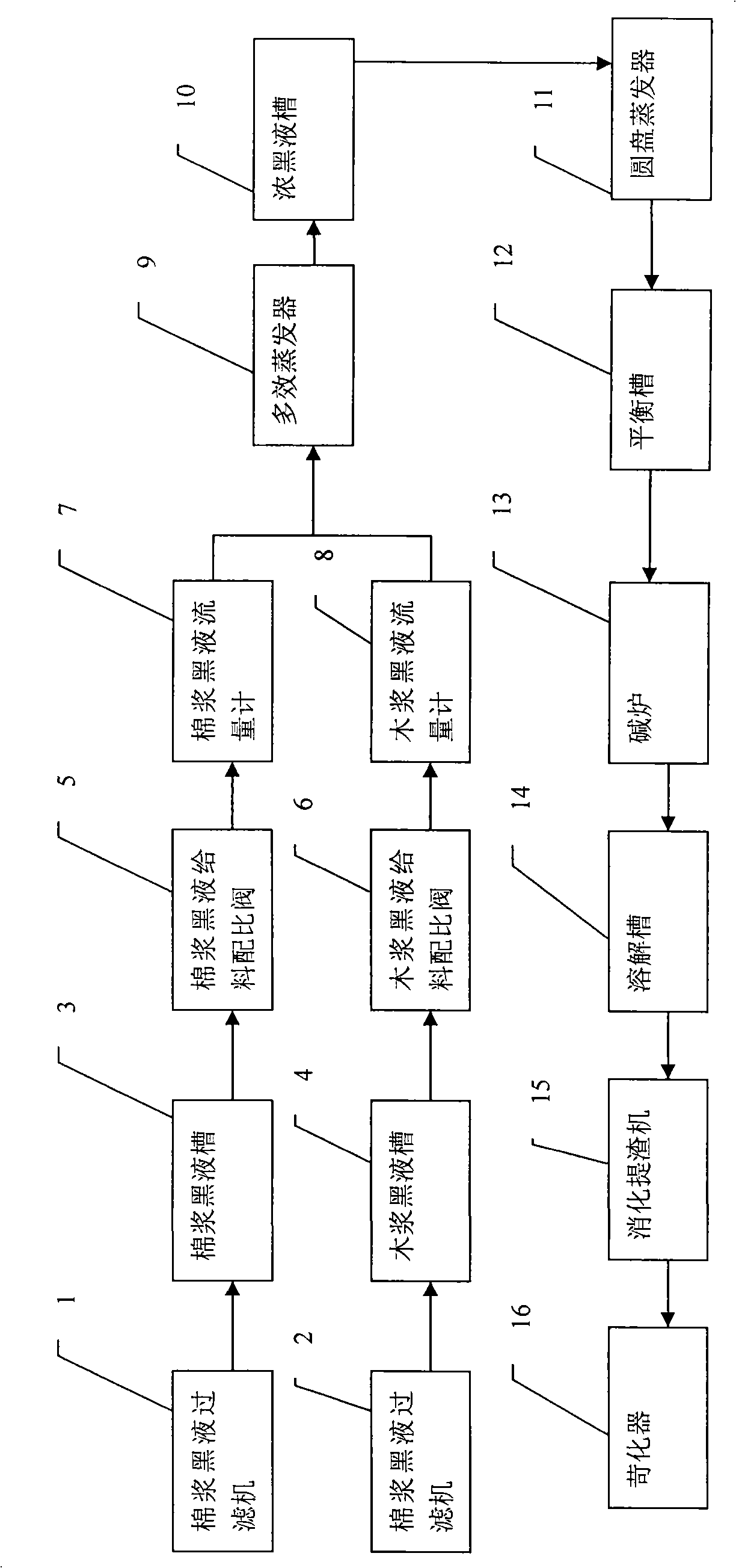

Process for treating chemical fiber cotton pulp black liquor

A treatment process and black liquor technology, which are applied in the fields of water/sewage multi-stage treatment, heating water/sewage treatment, processing wastewater treatment, etc., which can solve the problems of increased treatment costs, low combustion value, and difficulty in meeting national discharge standards for wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using the above process, when the chemical fiber cotton pulp black liquor and wood pulp black liquor are mixed in a ratio of 1: 2.0-1: 2.66, they are evaporated by an evaporator until the solid content in the mixed black liquor is between 43% and 44%. The solid content of the furnace concentrated black liquor is between 45% and 46%. It is difficult to dry the black liquor during the combustion process of the alkali recovery furnace. Around 65%.

Embodiment 2

[0019] Using the above process, when the chemical fiber cotton pulp black liquor and wood pulp black liquor are mixed in a ratio of 1:2.7-1:3.0, the solid content in the mixed black liquor is evaporated by an evaporator until the solid content is between 46%-47%. The solid content of the furnace concentrated black liquor is between 53% and 54%. During the combustion process of the alkali recovery furnace, the black liquor is well dried, no need to add heavy oil to support the combustion, and there is no phenomenon of alkali ash flying off. The steam production is relatively high, and the alkali recovery rate is in the About 80%.

Embodiment 3

[0021] Using the above process, when the mixing ratio of chemical fiber cotton pulp black liquor and wood pulp black liquor is more than 1:3.5, the solid content in the mixed black liquor is evaporated by the evaporator until the solid content of the mixed black liquor is above 48%, and the solid content of the concentrated black liquor entering the furnace is at More than 55%, the black liquor is well dried during the combustion process of the alkali recovery furnace, without the need for aggravated oil to support combustion, and there is no phenomenon of alkali ash flying off, the gas production is higher than that of Example 2, and the alkali recovery rate is above 80%.

[0022] In summary, when the mixing ratio of chemical fiber cotton pulp black liquor and wood pulp black liquor is 1:2.7-1:3.5, the alkali recovery system can be used to effectively treat chemical fiber cotton pulp black liquor and wood pulp black liquor, and recover The NaOH solution is used as alkali for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com