Multifunctional tobacco leaf stack sealing storage method capable of adjusting storage environment

A multi-functional, tobacco leaf technology, applied in botany equipment and methods, tobacco, tobacco processing, etc., can solve the problems of difficult conversion of functions, insecurity, and insects in tobacco leaves, and achieve the effect of cost saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

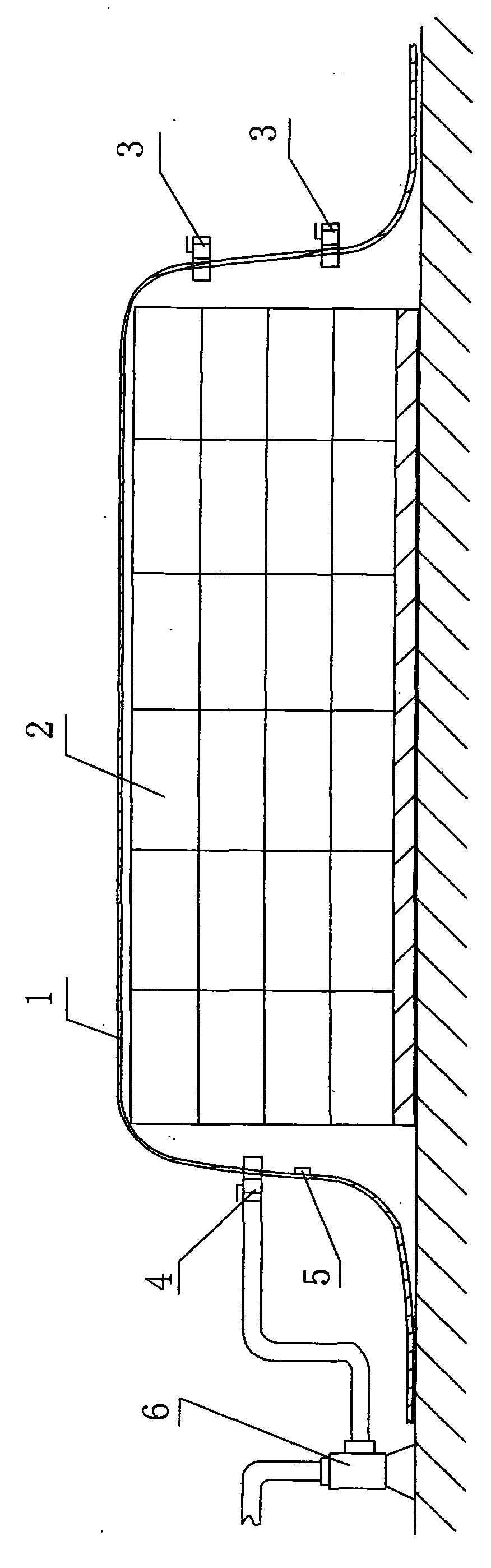

[0045] Such as figure 1 As shown, the multifunctional tobacco leaf stacking sealed storage method that can control the storage environment comprises the following steps:

[0046] 1) Construct a sealed space for stacking tobacco leaves that can regulate the storage environment:

[0047] First prepare equipment (prepare tobacco leaf stacking sealing tent), tobacco leaf stacking sealing tent comprises plastic sealing tent 1, air intake control joint 3, air outlet control joint 4, and plastic sealing tent is made of plastic film; Then use plastic sealing tent 1 pair The stacked tobacco leaves 2 are covered, and the stacked tobacco leaves 2 are enclosed in a sealed space (the stacked tobacco leaves 2 are located in the sealed space surrounded by the plastic airtight tent of the tobacco leaf stacked tent, that is, the stacked tobacco leaves are fully covered. of the seal);

[0048] Adopt 1~4 intake control joints 3 to be arranged (fixed) on the side face of plastic airtight tent 1...

Embodiment 2

[0071] Substantially the same as Example 1, the difference is: the gas fumigation and desinsection of step 2) adopts:

[0072] Connect the air intake control joint 3 with the sulfuryl fluoride gas generating device (that is, the steel cylinder is filled with liquid sulfuryl fluoride, which is connected to the air intake control joint through connecting pipes and valves, and becomes gaseous after being released) to form a gas fumigation and insecticide system , open the air inlet control joint 3 (close the air outlet control joint 4 or connect the air outlet control joint 4 with the sulfuryl fluoride gas generating device to form a cycle), and release sulfuryl fluoride gas into the sealed space surrounded by the plastic airtight tent for gas fumigation and killing Insects, the concentration of sulfuryl fluoride gas in the sealed space surrounded by plastic airtight tents reaches ≥5g / m 3 And after maintaining for 3 days (that is, the fumigation and insecticidal effect can be rea...

Embodiment 3

[0076] Substantially the same as Example 1, the difference is: the gas fumigation and desinsection of step 2) adopts:

[0077] Connect the air intake control joint 3 with the nitrogen outlet of the nitrogen generator, and connect the air outlet control joint 4 with the gas return port of the nitrogen generator to form a closed gas fumigation and insecticide system; open the air intake control joint 3, Gas outlet control joint 4, turn on the nitrogen generator, release nitrogen into the sealed space surrounded by plastic airtight tents for gas fumigation and insecticide (by continuously replacing air through circulation), the content of nitrogen in the sealed space surrounded by plastic airtight tents After reaching ≥95% (volume fraction) and maintaining it for 15 days; close the inlet control joint 3 and the outlet control joint 4, and separate the inlet control joint 3 and the outlet control joint 4 from the nitrogen generator respectively.

[0078] No step 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com