Spherical filling body

A filler, spherical technology, used in fire rescue and other directions, can solve the problems of not gaining market penetration, not suitable for preventing flames from extinguishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

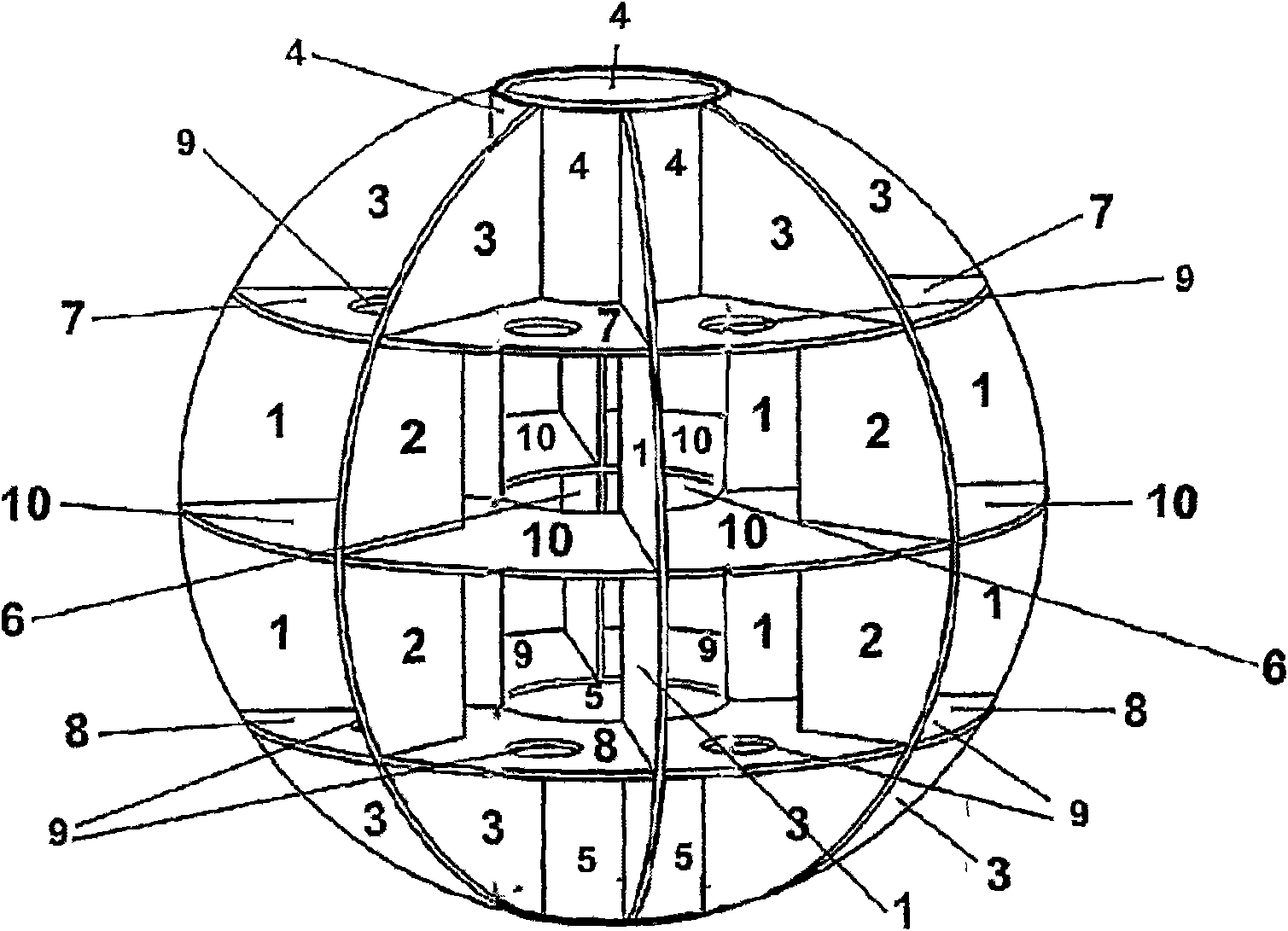

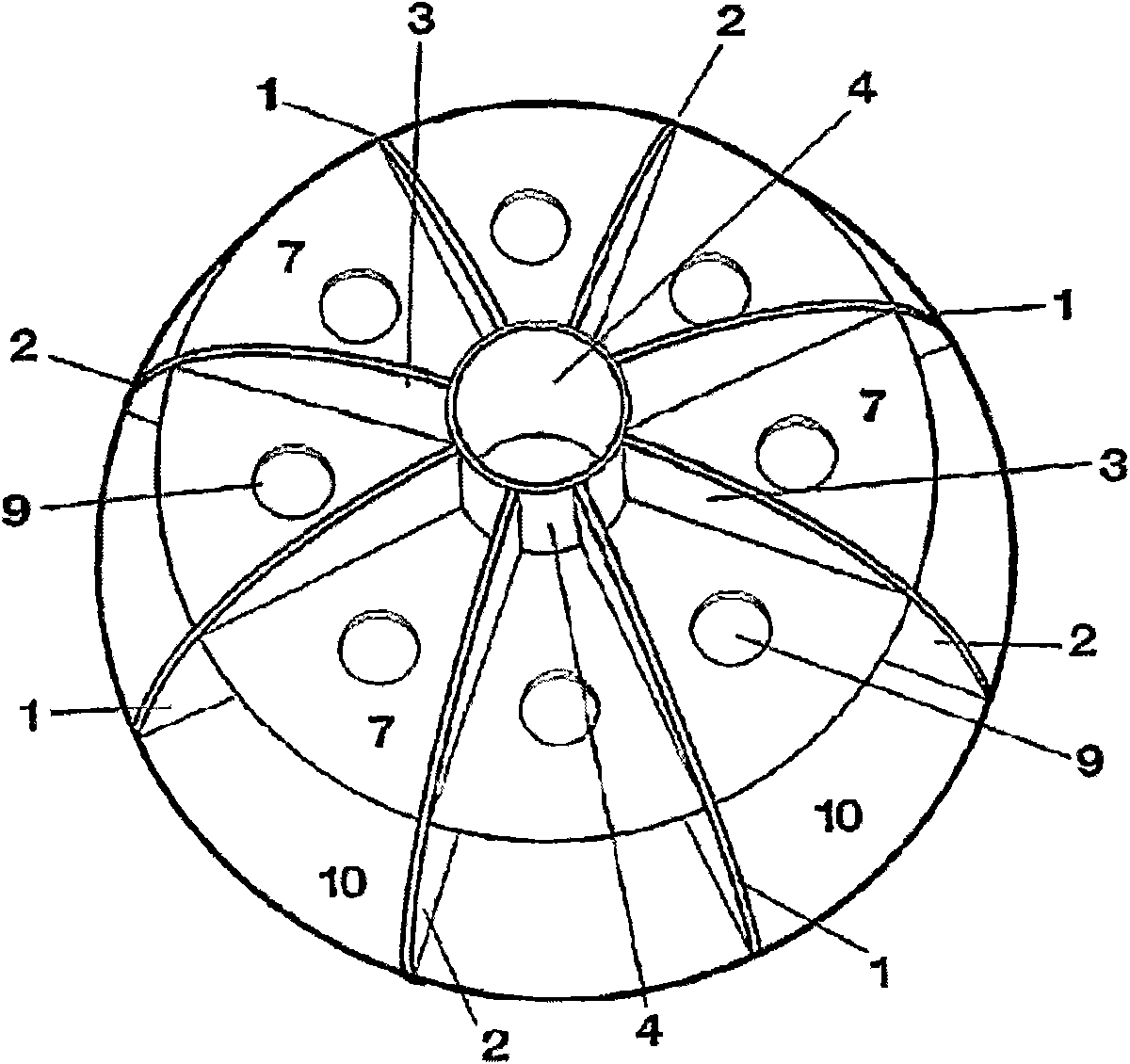

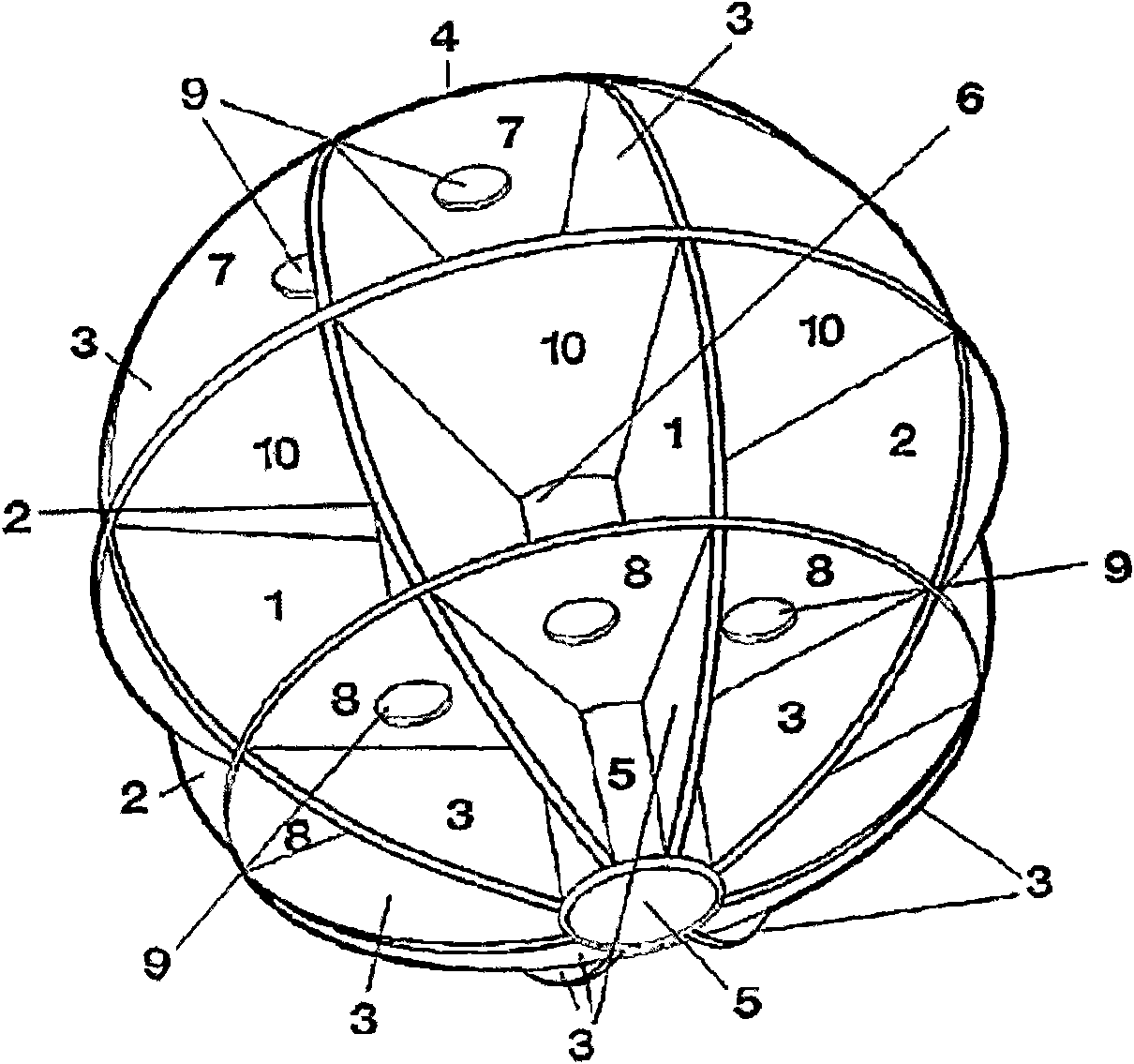

[0045] figure 1 , figure 2 and image 3 A spherical packing body according to the invention is shown, which is formed from a plurality of disc-shaped circular vertical planes 1 , 2 and 3 and disc-shaped circular horizontal planes 7 , 8 and 10 extending parallel to each other. Circular opening 6 is positioned at the center of horizontal plane 10, and described circular opening 6 is formed in the center together with the circular sleeve-shaped body 4 of upward inward opening and the circular sleeve-shaped body 5 of downward inward opening from upper sleeve-shaped body 4 to the axial through-pipe of the lower sleeve-shaped body 5, wherein the inner diameters of the sleeve-shaped and inwardly open circular bodies 4 and 5 and the circular opening 6 are the same. From the outer edge of the spherical body a vertical plane 1 extends to the edge of each circular opening 4 , 5 and 6 and to the edge of a horizontal plane 7 , 10 and 8 respectively extending around said opening in para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com