Nonmagnetic bimetallic strip driver used in transmission electron microscope

A technology of bimetal sheet and transmission electron microscope, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as hazards, influence of electron microscopes, inconvenience of observation and shooting, etc., and achieve the effect of wide application range and rich research objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

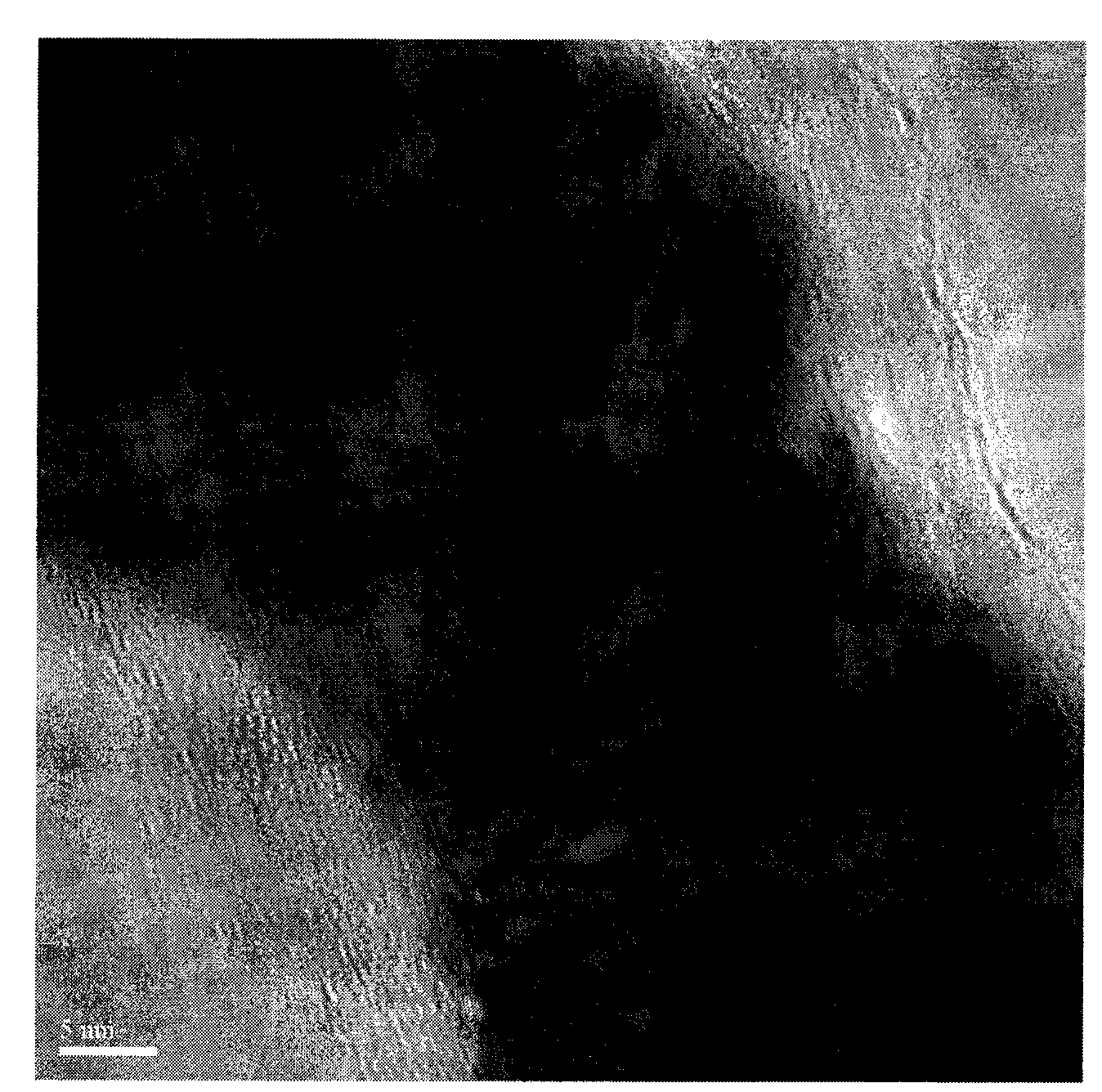

[0019] The device from bottom to top is: metal heat conduction frame with a thickness of 150um and a side length of 2.15mm. The non-magnetic single metal sheet is copper, with a thickness of 100um, a width of 300um, and a length of 2.5mm. The non-magnetic bimetal sheet is made of aluminum-magnesium alloy with a large linear expansion coefficient and bronze with a small linear expansion coefficient. The parts with large linear expansion coefficients of the two non-magnetic bimetal sheets are close to the two non-magnetic In the gaps between the bimetal sheets, the ones with the smallest coefficient of linear expansion are on the outside. The thickness of the non-magnetic bimetal sheets is 100um, the width is 350um, and the length is 2mm. Both ends of the non-magnetic single metal sheet are fixed on the opposite metal heat conduction frame, two non-magnetic bimetal sheets are arranged in parallel and fixed on the metal heat conduction frame, and one end of each non-magnetic bime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com