Resin composition with high thermal conductivity, no halogen and difficult fire retardance and pre-impregnated body and coating material thereof

A resin composition, high thermal conductivity technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of undisclosed flame retardant characteristics, unmentioned high thermal conductivity characteristics, etc., to improve service life and stability, high Effects of thermal conductivity, excellent heat resistance and flame resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The phosphorus-based epoxy resin (EEW=350g / eq of 75 parts by weight of solid type, Nanya Plastics Co., Ltd., product name: NPEP-200LA70, phosphorus content=2.6wt%), the bisphenol A type epoxy resin of 25 parts by weight ( EEW=186g / eq, South Asia Plastics Company, product name: NPEL-182E), the phenolic resin of 34.87 parts by weight and the 2-methylimidazole of 0.05 parts by weight, after being dissolved in 207.5 parts by weight of butanone, blending 250.5 parts by weight of high Thermally conductive powder, that is, a high thermally conductive halogen-free flame retardant composition (high thermally conductive powder accounts for 65%).

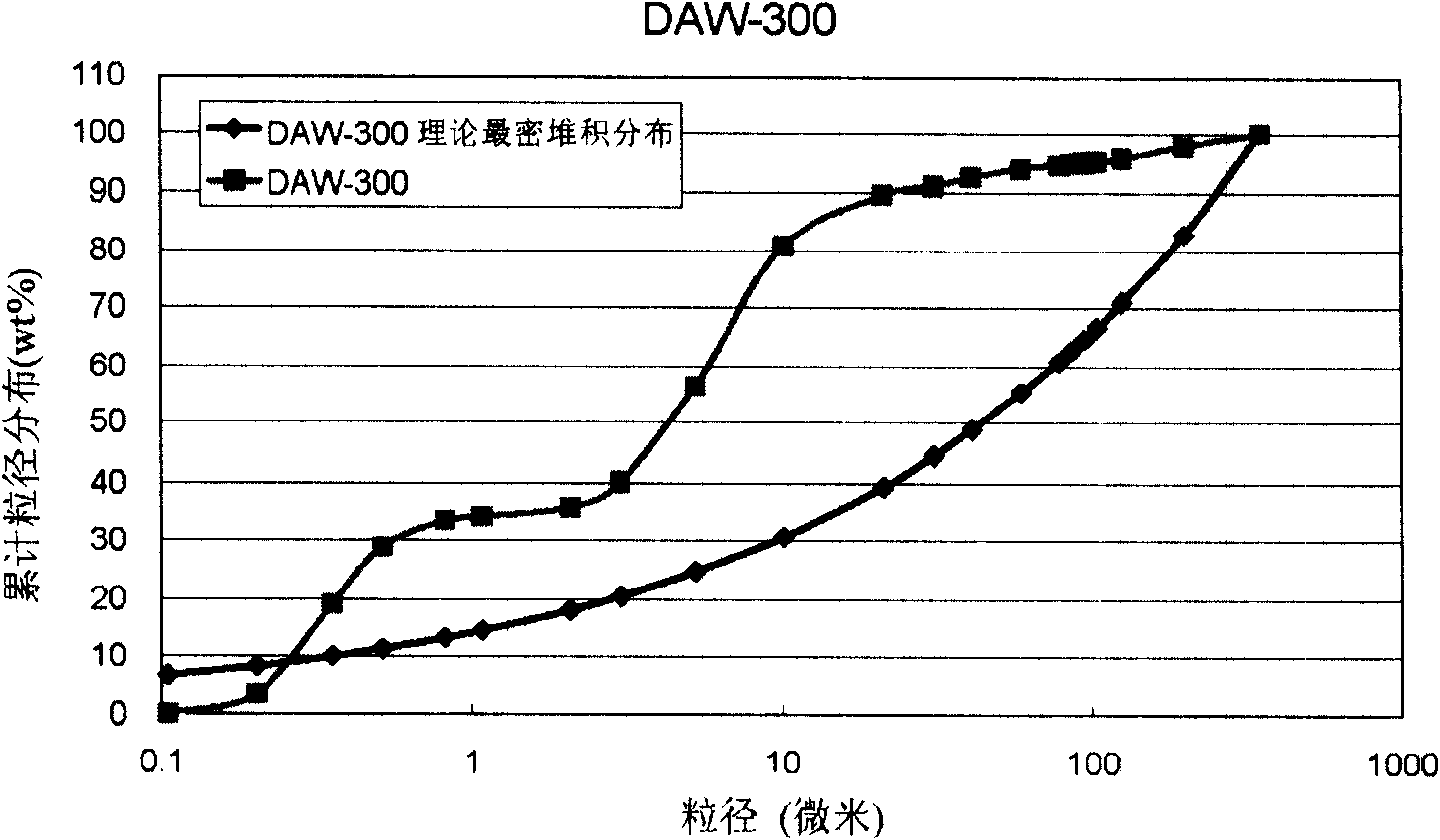

[0072] Among them, the high thermal conductivity powder (250.5 parts by weight) mixed into the above resin liquid is used to obtain the closest packing model of the high thermal conductivity powder by using the Horsfield model, and the specific ratio is 45.09 parts by weight of spherical alumina A (average particle diameter D50=5 μm), 5...

Embodiment 2

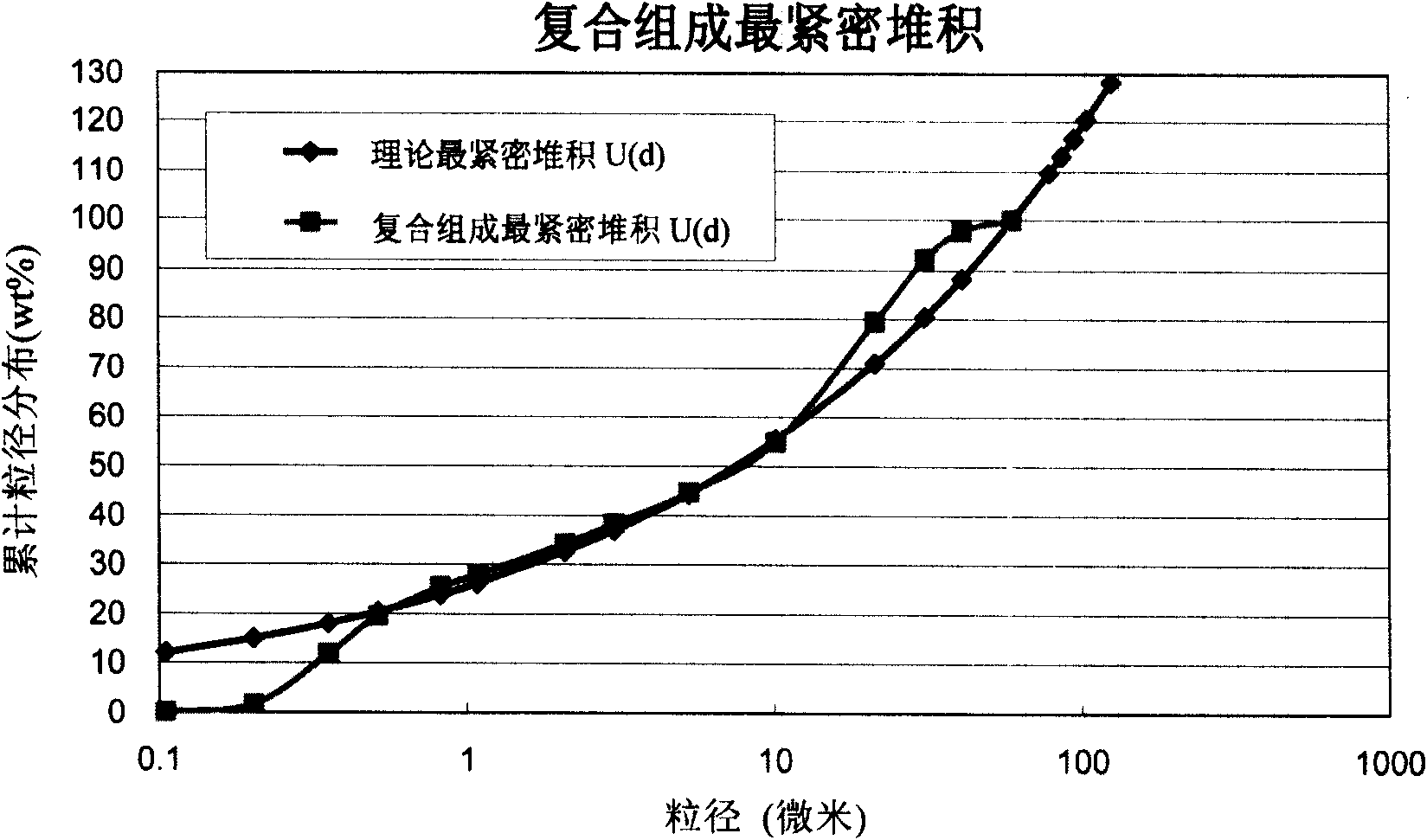

[0076] The resin solution formula in Example 1 was changed to blending 539.5 parts by weight of high thermal conductivity powder (accounting for 80% of the high thermal conductivity halogen-free flame retardant composition), and the Horsfield model was used to obtain the closest packing model of the high thermal conductivity powder, which The specific ratio is 97.11 parts by weight of spherical alumina A (average particle diameter D50=5 μm), 10.79 parts by weight of spherical alumina B (average particle diameter D50=0.5 μm) and 431.6 parts by weight of boron nitride (average particle diameter Diameter D50=5.5μm), where the actual packing curve of alumina powder is compared with the theoretical closest packing curve as figure 1 .

[0077] The physical properties of the prepared copper foil substrate were tested, and the results are shown in Table 1.

Embodiment 3

[0079] The formula of the resin solution is the same as that in Example 2, but the solid content of the resin solution is adjusted to 75wt%, and then coated on a 35 μm copper foil to form an adhesive-backed copper foil (RCC) with a coating thickness of 100 μm, and then laminated on the resin surface with a thickness of 35 μm The copper foil was laminated under the same conditions as in Example 1. Finally, the physical properties of the copper foil substrate were tested after the copper foil was etched. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com