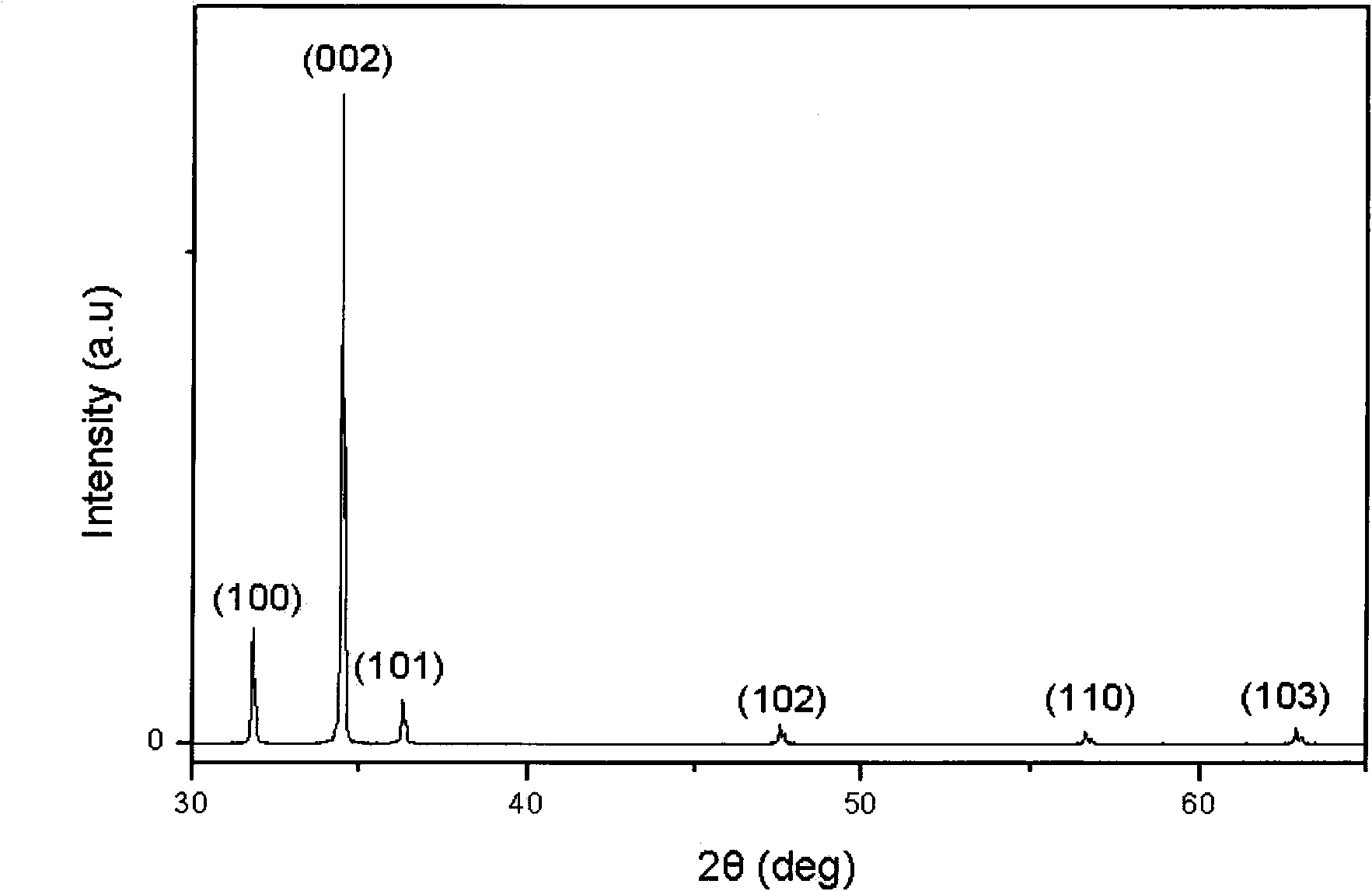

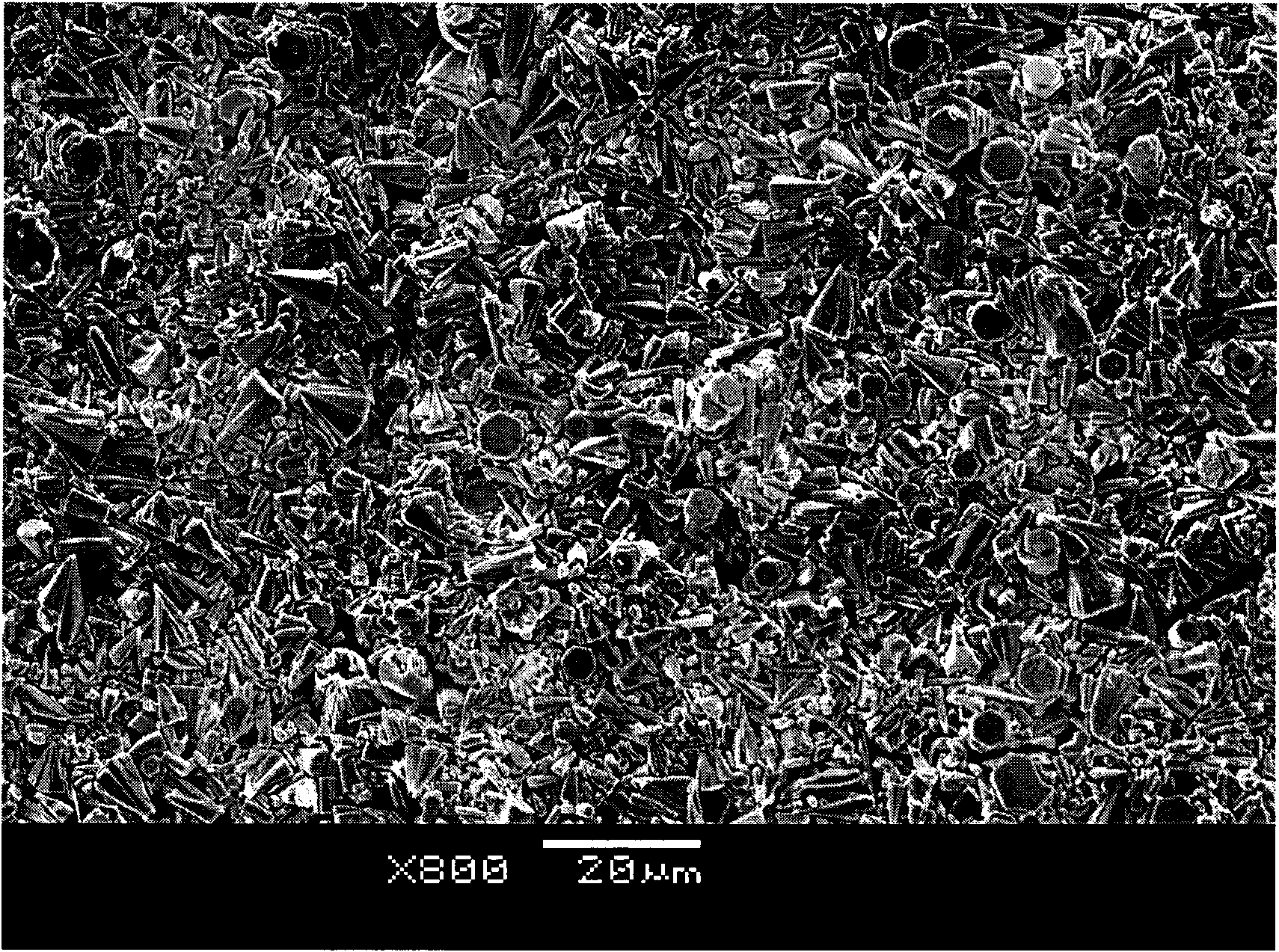

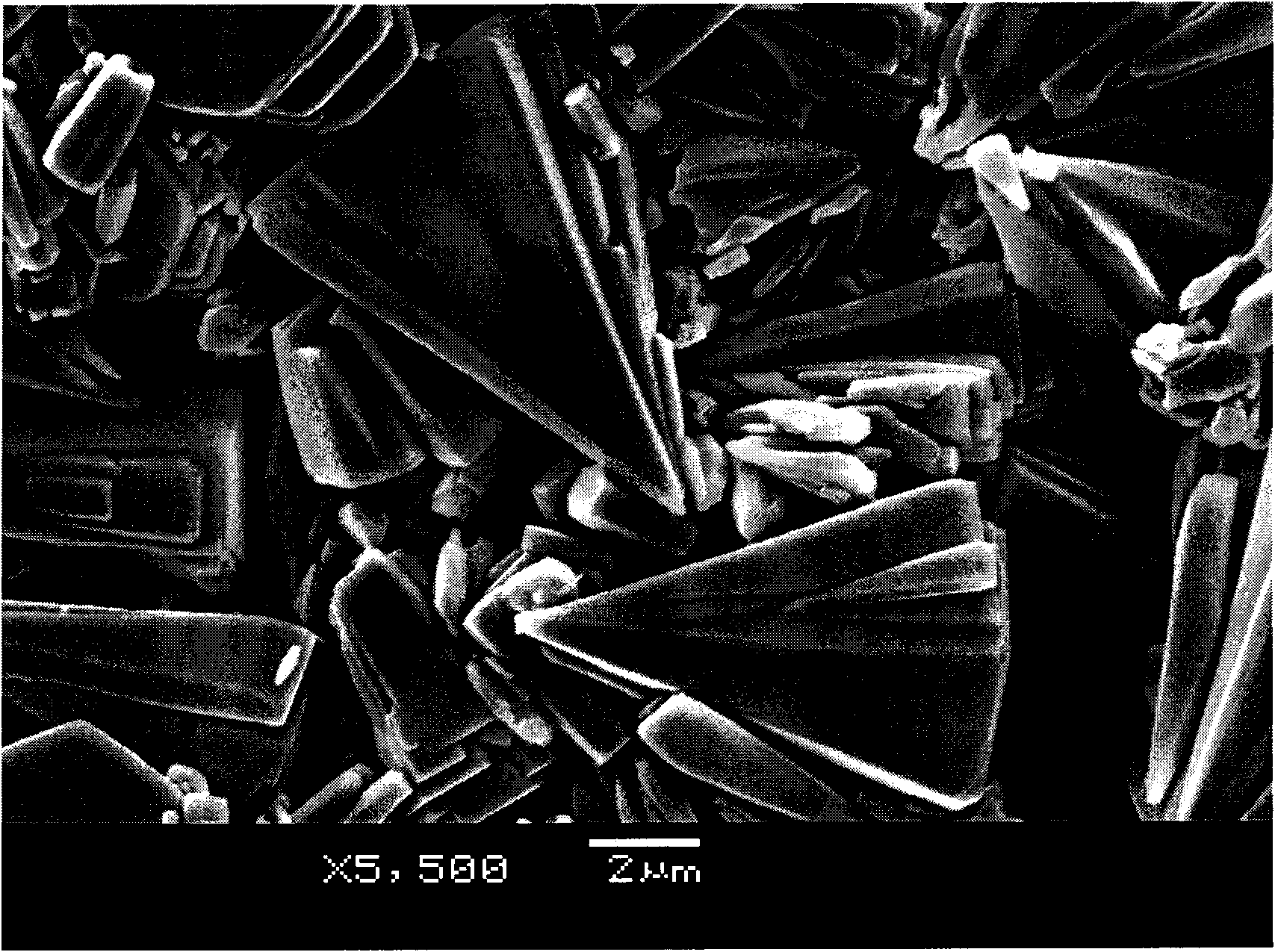

Semiconductor material with ZnO cone-shaped nano structure compounded on silicon chip and preparation method thereof

A nanostructure and semiconductor technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high cost, high repeatability, and harsh preparation method conditions, and achieve low cost, high repeatability, and low growth temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a, configure the reaction solution: zinc acetate (Zn(CH 3 COO) 2 ) powder is dissolved in water, and ammonia water is added to adjust the pH value of the solution to 7.5.

[0019] b. Grow ZnO conical nanostructures on silicon wafers: first put the cleaned silicon (100) wafers into the autoclave, then pour the above solution into the autoclave, seal the autoclave and put it into the blast drying box, keep the reaction at 60°C for 6 hours, and the desired material can be obtained after natural cooling.

Embodiment 2

[0021] a, configure the reaction solution: zinc acetate (Zn(CH 3 COO) 2 ) powder is dissolved in water, and ammonia water is added to adjust the pH value of the solution at 8.

[0022] b. Grow ZnO conical nanostructures on silicon wafers: first put the cleaned silicon (111) wafers into an autoclave, then pour the above solution into the autoclave, seal the autoclave and put it into the blast drying box, keep the reaction at 65°C for 5.5 hours, and the desired material can be obtained after natural cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com