Preparation method of activated carbon fiber photocatalysis net loaded with nano titanium dioxide

A nano-TiO2, activated carbon fiber technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of nano-TiO2 particle loading strength, loading uniformity and stability, etc. The effect of high surface area, high degradation efficiency, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The viscose-based activated carbon fiber felt (BET specific surface area is 1356m 2 ·g -1 , the pore volume is 0.292 cm 3 ·g -1 , with a size of 80×75×3 mm) immersed in an ammonia solution with a mass concentration of 28%, ultrasonically cleaned for 40 minutes, and then washed with deionized water three times; Washed with ionized water three times, then soaked activated carbon fiber felt in acetone for 20 min, washed with deionized water three times, and dried at 105 °C.

[0040] Dissolve 2.5g epoxy resin with an epoxy value of 0.25 in 100mL acetone to prepare an epoxy resin acetone solution, and then put 5.000g nanometer titanium dioxide powder (Degussa P25) with an average particle size of 50 nanometers into the solution. In the above solution, shear and disperse for 1 hour at a rotational speed of 7000 rpm to form a uniformly dispersed milky white slurry. The pretreated activated carbon fiber mat is immersed in the milky white slurry, taken out after 25 minutes, a...

Embodiment 2

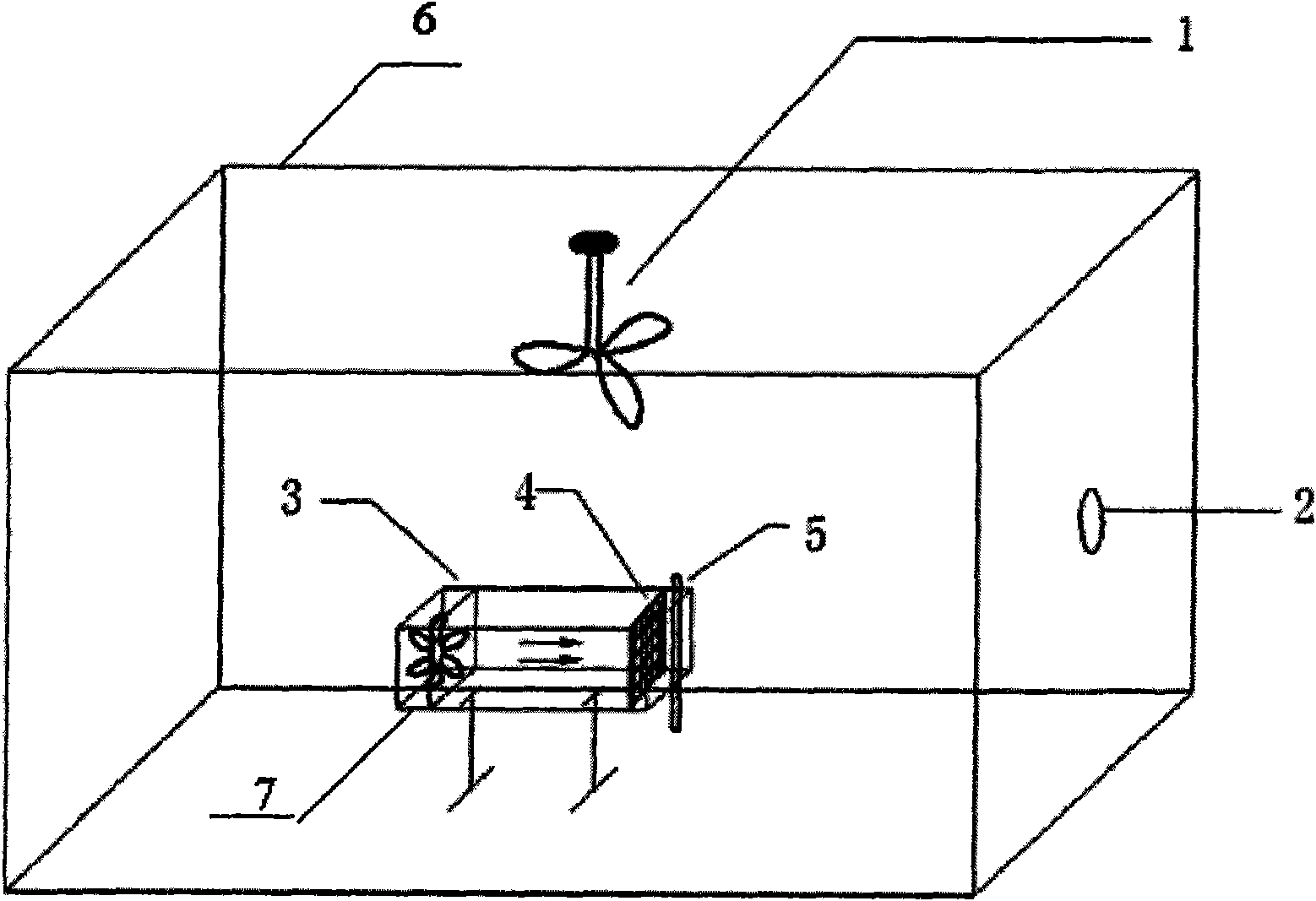

[0044] The same activated carbon fiber-supported nano-TiO was prepared in the same manner as in Example 1 2 Photocatalytic mesh. put it in figure 1 In the apparatus shown, a small tubular reactor is used to hold it. Put 10 μL of toluene solution with a mass concentration of 99.5%, and volatilize naturally. When completely volatilized and the adsorption reached equilibrium, turn on the UV lamp. After 3h, the degradation rate of benzene gas was measured to reach 35%. The toluene gas in the airtight chamber was emptied and then put into 10 μL of 99.5% toluene solution to volatilize in the airtight chamber. After the adsorption was balanced, the UV lamp was turned on. After 3 hours, the toluene gas degradation rate reached 33%. The photocatalytic degradation experiment of toluene was repeated again, and the degradation rate of toluene reached 30%.

Embodiment 3

[0046] The same viscose-based activated carbon fiber felt used in Example 1 was immersed in an ammonia solution with a mass concentration of 20%, ultrasonically cleaned for 20 min, and then washed three times with deionized water; then with a mass concentration of 40% nitric acid solution, ultrasonication After treatment for 20 min, washed three times with deionized water; then immersed activated carbon fiber felt in acetone for 10 min, washed with deionized water three times, and dried at 105 °C. The pretreated activated carbon fiber mat was dipped in the milky white slurry prepared according to Example 1, and the rest of the steps were the same as those of Example 1. Among them, the epoxy value of the epoxy resin was 0.45.

[0047] The prepared photocatalytic material has a specific surface area of 610m 2 ·g -1 , pore volume 0.216cm 3 ·g -1 , the average pore size is 3.41nm, and the unit mass of activated carbon fiber TiO 2 The load factor is 53%. The wind is 5m s -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com