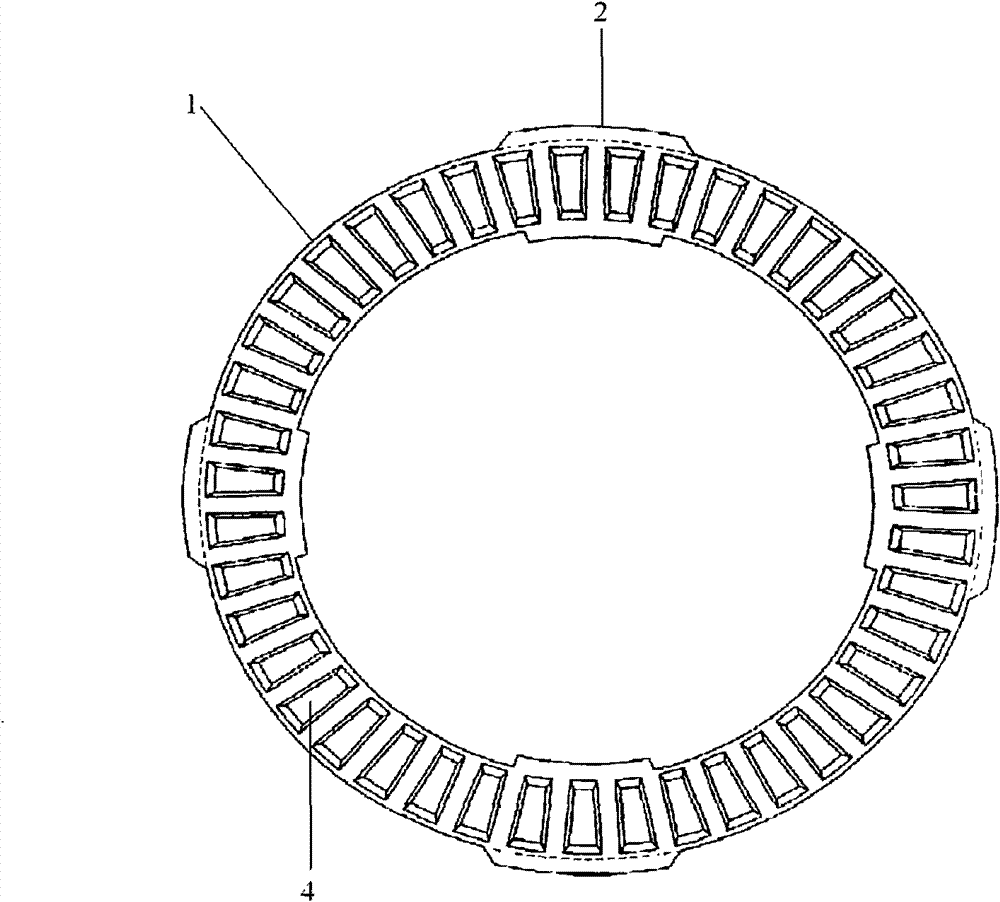

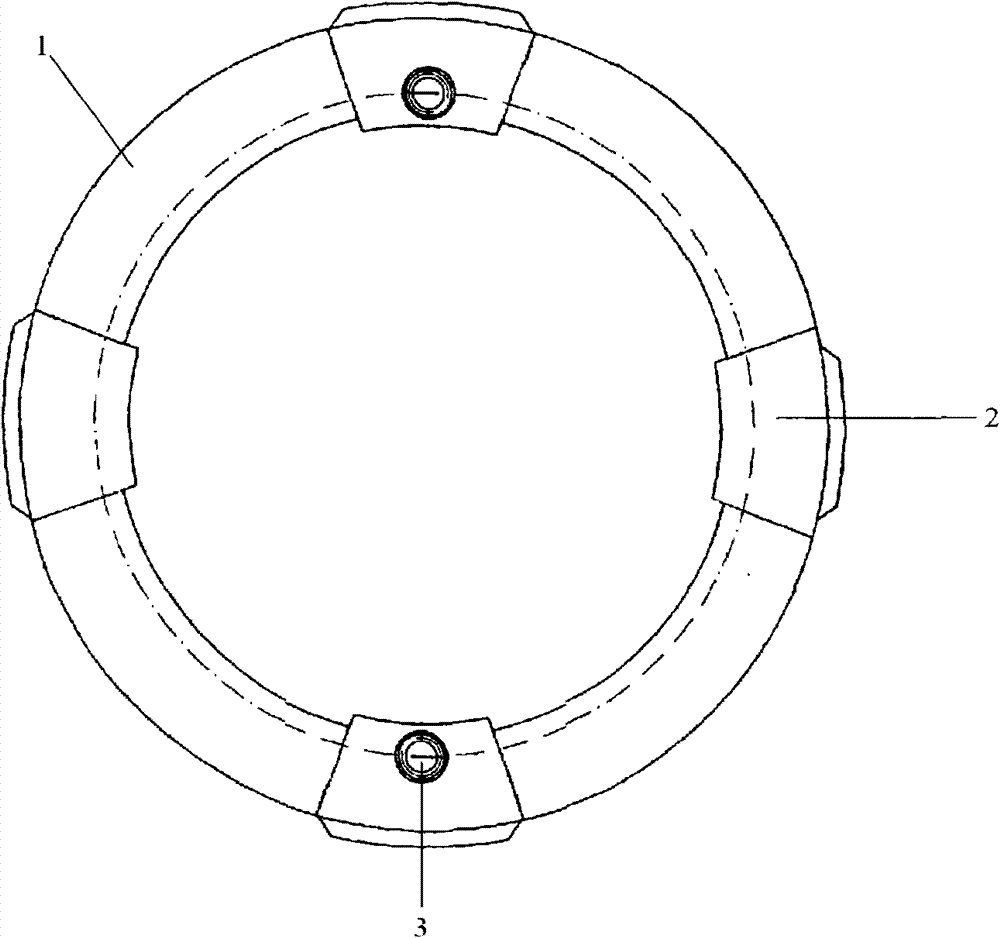

Powder metallurgy automobile ABS speed sensing disk and method for preparing same

A powder metallurgy and speed technology, applied in the field of powder metallurgy speed detection disc and its preparation, to achieve the effects of high yield, uniform quality and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After mixing Cu powder, Fe powder, C powder and Mo powder evenly, put them into a molding machine for molding; the parts by weight of each component are: Cu: 3.0, C: 1.0, Mo: 2.0, and the rest is Fe powder; Control the temperature at 1050°C, sinter; oil immerse in anti-rust oil once; process and dry oil in sequence; sandblasting and Dacromet in sequence, and the powder metallurgy automotive ABS speed detection plate is prepared.

[0022] After testing, the invented powder metallurgy automotive ABS speed detection disc, its shape, hardness and precision can meet the requirements of use, the hardness Hv10 is 70, and the salt spray test is 500 hours; the adhesion of Dacromet is above 3.5; parallel The density is below 0.10mm; the density of any part is above 6.8g / cm3.

Embodiment 2

[0024] After mixing Cu powder, Fe powder, C powder and Mo powder evenly, put them into a molding machine for molding; the parts by weight of each component are: C: 0.30, Mo: 1.0, and the rest is Fe powder; temperature control 1200°C , sintering; oil immersion anti-rust oil; sequential processing and oil drying; sequential sandblasting and Dacromet, that is, the preparation of powder metallurgy automobile ABS speed detection plate.

[0025] After testing, the invented powder metallurgy automobile ABS speed detection disc, its shape, hardness and precision can meet the requirements of use, the hardness Hv10 is above 65, the salt spray test is more than 485 hours; the adhesion of dacromet is above 3.5 ; Parallelism below 0.10mm; Density above 6.8g / cm3.

Embodiment 3

[0027] After mixing Cu powder, Fe powder, C powder and Mo powder evenly, put them into a molding machine for molding; the parts by weight of each component are: Cu: 1.0, C: 0.70, Mo: 1.5, and the rest is Fe powder; Temperature control at 1120°C, sintering; oil immersion in anti-rust oil; sequential processing and oil drying; sequential sandblasting and dacromet, the powder metallurgy automobile ABS speed detection plate is prepared.

[0028] After testing, the invented powder metallurgy automotive ABS speed detection disc, its shape, hardness and precision can meet the requirements of use, the hardness Hv10 is above 60, the salt spray test is more than 480 hours; the adhesion of Dacromet is above 3.5 ; Parallelism below 0.10mm; Density above 6.8g / cm3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com