Method for preparing nano-structure of magnesium

A nanostructure and block-forming technology is applied in the field of preparation of magnesium nanostructures, which can solve the problems of less than 20% Mg actual content, growth of nanoparticles, easy hydrolysis and oxidation of nanoparticles, etc., and achieves low cost and diffusion distance. The effect of reduced, excellent hydrogen absorption and desorption kinetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

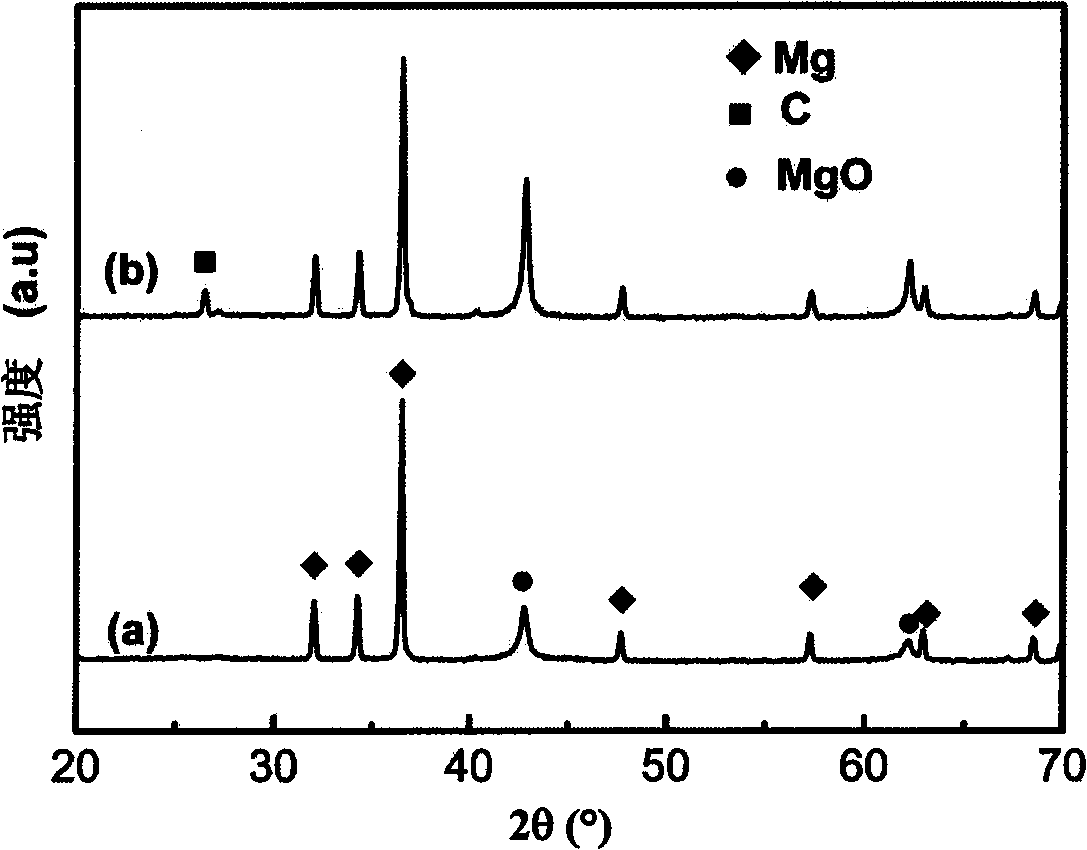

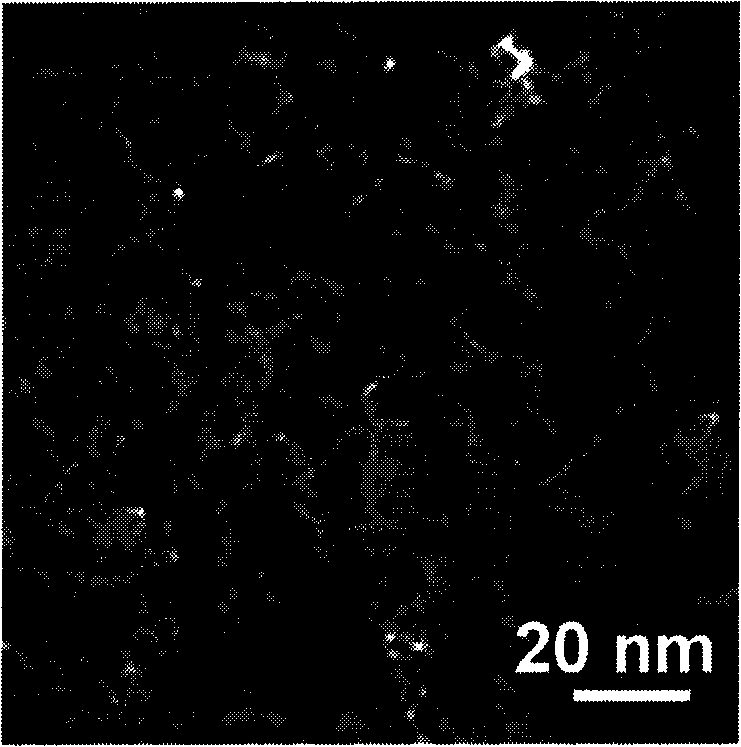

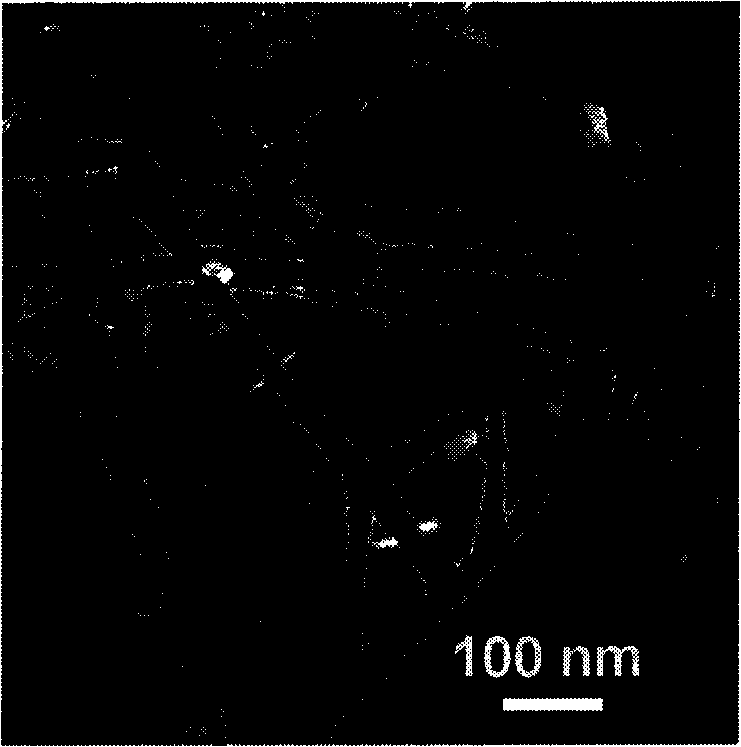

[0019] Embodiment 1, synthetic particle size is the Mg particle of 20nm

[0020] (1) Put MgO and activated carbon with a molar ratio of 1:2 into a ball mill jar, take out after ball milling at a speed of 200rpm for 2 hours, and press into tablets under a pressure of 700bar;

[0021] (2) Put the pressed sheet in a hydrogen plasma arc heating furnace, and after vacuuming, under an Ar atmosphere with a total pressure of 0.8 bar, apply DC arc plasma to obtain Mg nanoparticles;

[0022] (3) Stop heating and vacuumize. After the system cools down, slowly pass air into the furnace for passivation, and take out the sample after 48 hours of passivation.

Embodiment 2

[0023] Embodiment 2, synthetic particle size is the Mg particle of 20nm

[0024] (1) Put MgO and activated carbon with a molar ratio of 1:3 into a ball mill jar, take out after ball milling at a speed of 200rpm for 2 hours, and press into tablets under a pressure of 700bar;

[0025] (2) Put the pressed sheet in a hydrogen plasma arc heating furnace. After vacuuming, arc discharge is started under an Ar atmosphere with a pressure of 0.9 bar, and then part of the Ar gas is extracted, and N 2 Gas, 40% N at a total pressure of 0.9 bar 2 In / Ar mixed atmosphere, apply DC arc plasma to obtain Mg nanoparticles;

[0026] (3) Stop heating and vacuumize. After the system cools down, slowly pass air into the furnace for passivation, and take out the sample after 48 hours of passivation.

Embodiment 3

[0027] Embodiment 3, synthetic particle size is the Mg particle of 20nm

[0028] (1) Put MgO and activated carbon with a molar ratio of 1:3 into a ball mill jar, take it out after ball milling at a speed of 200rpm for 2 hours, add a small amount of polyvinylidene fluoride (PVDF) as a binder, and make small ball;

[0029] (2) Put the ball in the hydrogen plasma arc heating furnace, after vacuuming, start the arc discharge in the Ar atmosphere with a pressure of 0.5 bar, then extract part of the Ar gas, and pass it into the H 2 Gas, 40% H at a total pressure of 0.5 bar 2 In / Ar mixed atmosphere, apply DC arc plasma to obtain Mg nanoparticles;

[0030] (3) Stop heating and vacuumize. After the system cools down, slowly pass air into the furnace for passivation, and take out the sample after 48 hours of passivation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com