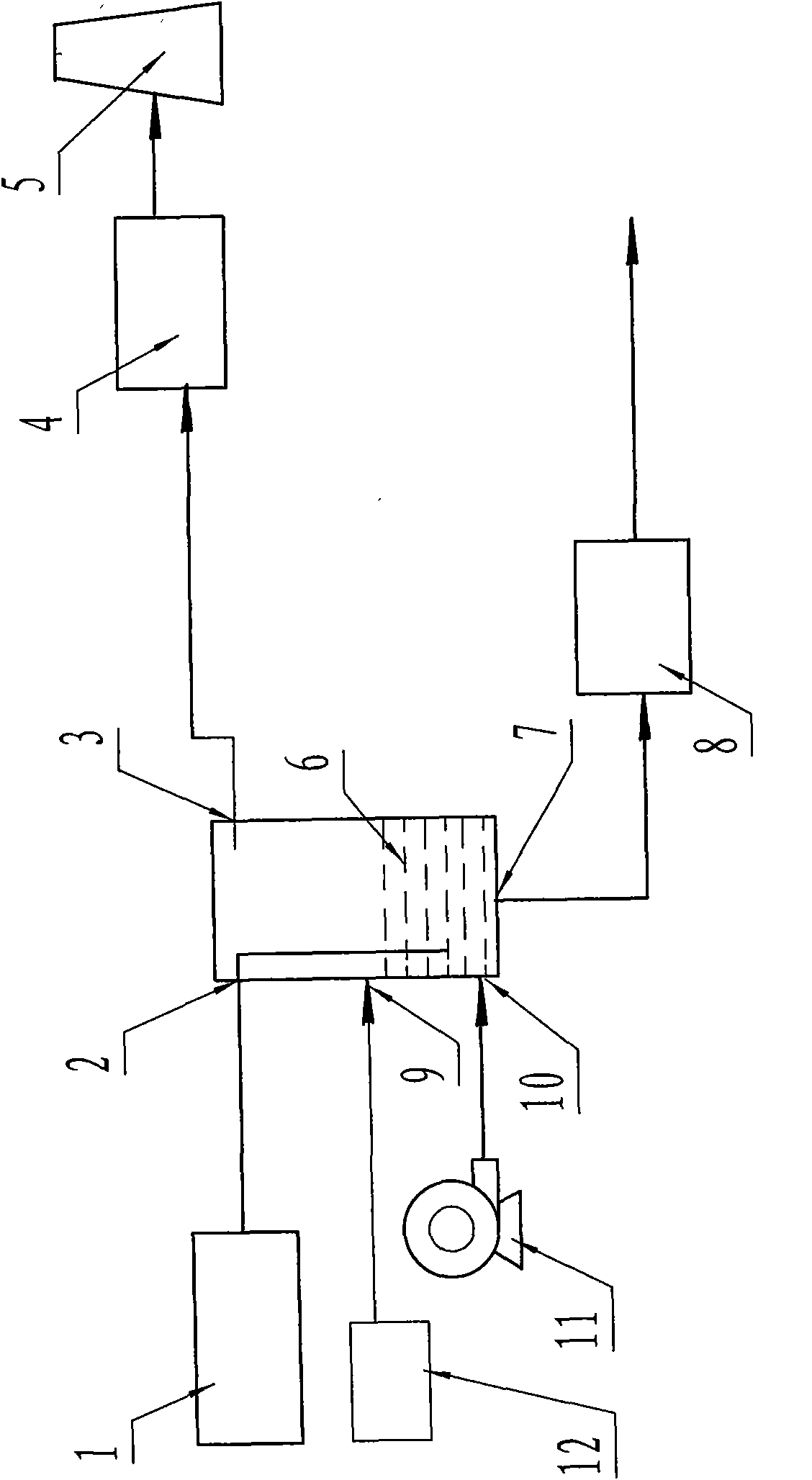

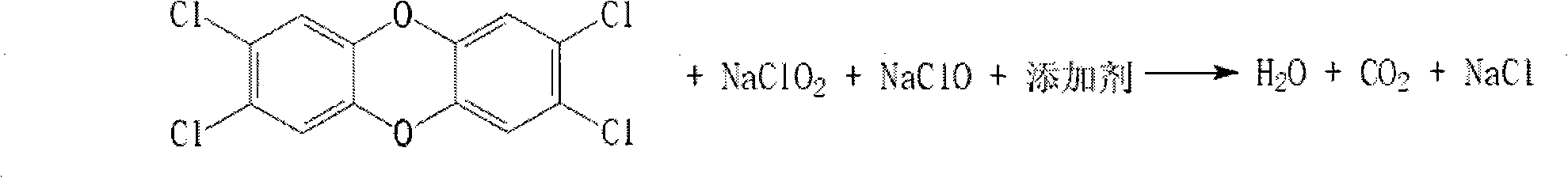

Liquid phase method for removing dioxin-like compounds from flue gas and device thereof

A technology of dioxin and flue gas, applied in the field of flue gas purification, can solve the problems of inability to achieve standard discharge, difficult practical application, low removal efficiency, etc., and achieve easy popularization and application, high utilization rate, and high removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

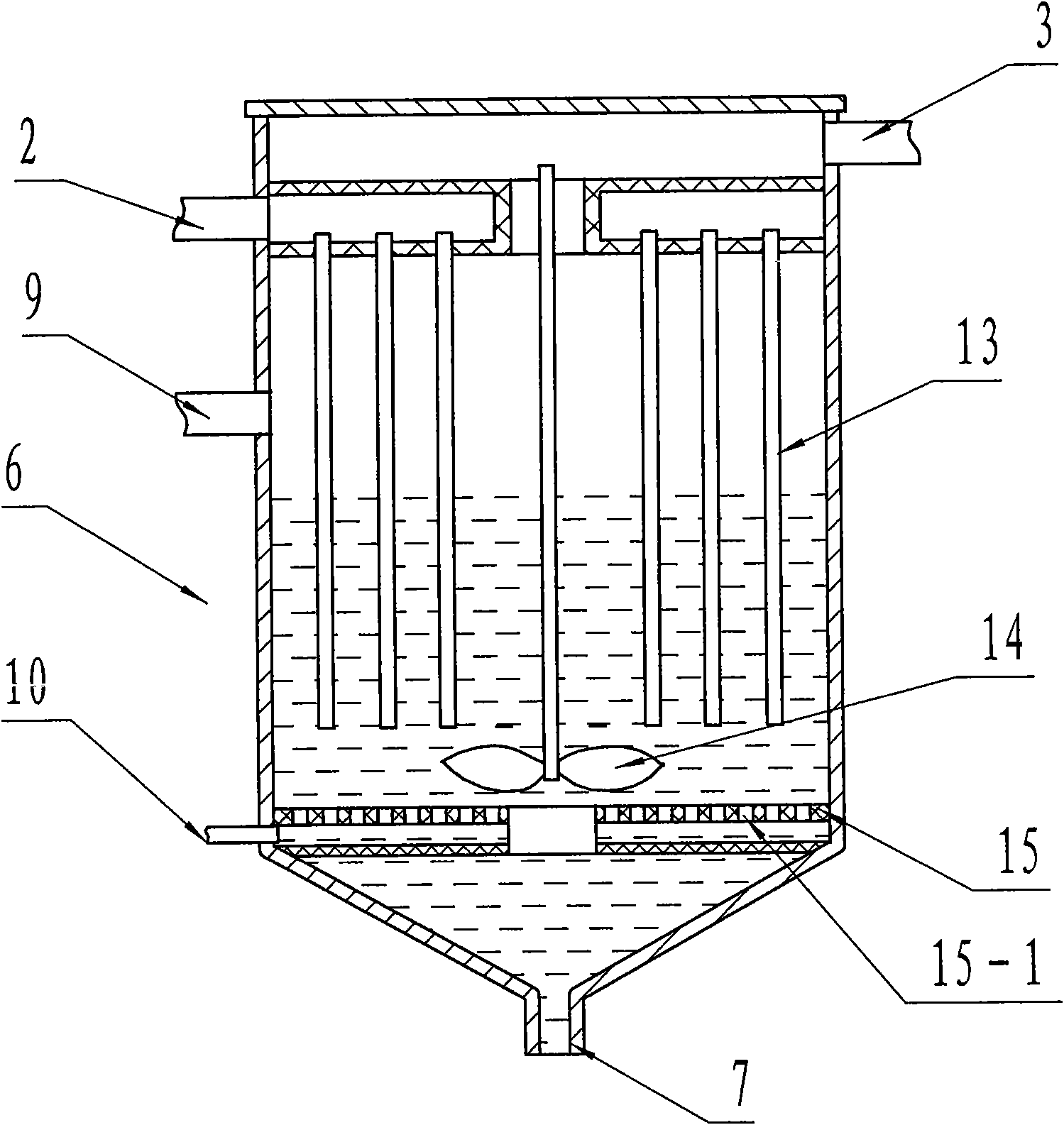

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: take by weighing NaClO by proportioning 2 , NaClO and NaHCO 3 , add to the absorbent reactor, add water and mix well, so that the absorbent includes 0.01M NaClO 2 , 0.01M NaClO and 0.002M sodium bicarbonate NaHCO 3 . The pH value was adjusted to 8 with sodium hydroxide NaOH solution, and the desired absorbent was obtained by activating in the dark for 5 minutes at a temperature of 25°C.

Embodiment 2

[0023] Embodiment 2: take by weighing NaClO 2 , NaClO and Ca(ClO) 2 , add to the absorbent reactor, add water and mix well, so that the absorbent includes 0.1M NaClO 2 , 0.06M NaClO and 0.004M Ca(ClO) 2 . The pH value was adjusted to 9 with sodium hydroxide NaOH solution, and the desired absorbent was obtained by activating in the dark for 10 minutes at a temperature of 20°C.

Embodiment 3

[0024]Embodiment 3: take by weighing NaClO by proportioning 2 , NaClO and H 2 o 2 , add to the absorbent reactor, add water and mix well, so that the absorbent includes 0.05M NaClO 2 , 0.08M NaClO and 0.05M H 2 o 2 . The pH value was adjusted to 9.5 with sodium hydroxide NaOH solution, and the required absorbent was obtained by activating in the dark for 7 minutes at a temperature of 28°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com