Method for flattening surface of polysilicon

A surface planarization and polysilicon technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of reducing device reliability and service life, and achieve uniform etching rate, uniform distribution trend, polysilicon flat surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the present embodiment, the operating condition of rapid thermal oxidation is: temperature is 1100 ℃, O 2 The flow rate is 8SLM (liters per minute under standard conditions), and the time for rapid thermal oxidation treatment is 3 minutes;

[0044] The power of penetration etching is 400W, the pressure is 100 mTorr, and the etching gas is CF 4 , and its flow rate is 35sccm;

[0045] The power of the main etching is 500W, the pressure is 45mTorr, and the etching gas and its flow rate are respectively 40sccmCl 2 / 60sccmHBr;

[0046] The power of over-etching is 300W, the pressure is 110mTorr, and the etching gas and its flow rate are respectively 20sccmCl 2 / 60sccmHBr / 5sccmHe-O 2 .

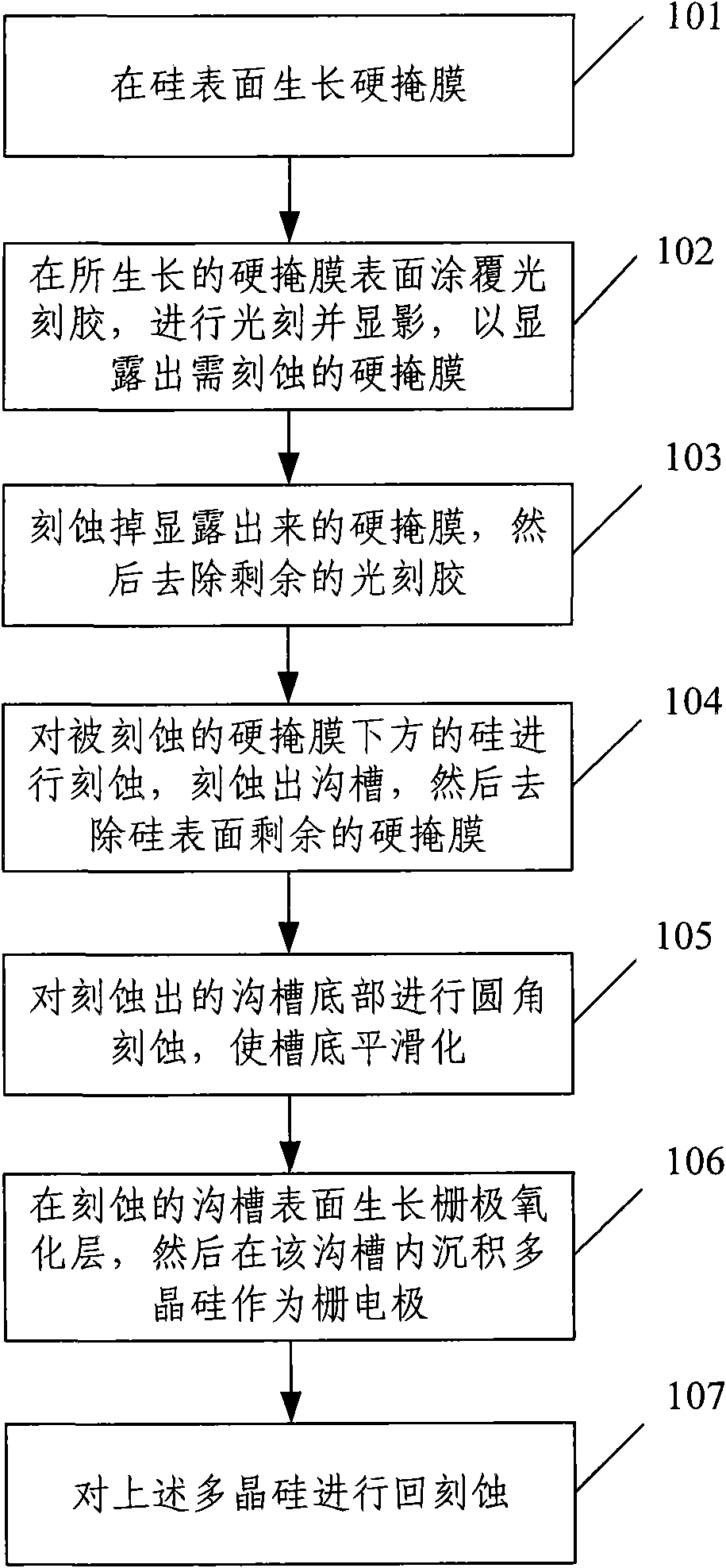

[0047] Figure 4 It is the process flow diagram of polysilicon surface planarization of the present invention, in conjunction with image 3 , Figure 4 Shown in A~4H, the method for planarizing the polysilicon surface of the present invention comprises the following steps:

[0048...

Embodiment 2

[0065] In the present embodiment, the operating condition of rapid thermal oxidation is: temperature is 900 ℃, O 2 The flow rate is 7SLM, and the time for rapid thermal oxidation treatment is 5 minutes;

[0066] The power of penetration etching is 250W, the pressure is 75 mTorr, and the etching gas is CF 4 , and its flow rate is 30 sccm;

[0067] The power of the main etching is 400W, the pressure is 40mTorr, and the etching gas and its flow rate are respectively 30sccmCl 2 / 30sccmHBr;

[0068] The power of over-etching is 250W, the pressure is 40mTorr, and the etching gas and its flow rate are respectively 30sccmCl 2 / 30sccmHBr / 8sccmHe-O 2 .

[0069] The method for planarizing the polysilicon surface of the present invention comprises the following steps:

[0070] b1) A high-temperature thermal oxide layer is grown on the surface of the single crystal silicon substrate 1, and then tetraethoxysilane is deposited on the high-temperature thermal oxide layer, and tetraethox...

Embodiment 3

[0085] In the present embodiment, the operating condition of rapid thermal oxidation is: temperature is 1100 ℃, O 2 The flow rate is 8SLM (liters per minute under standard conditions), and the time for rapid thermal oxidation treatment is 3 minutes;

[0086] The power of penetration etching is 450W, the pressure is 120mTorr, and the etching gas is CF 4 , and its flow rate is 50 sccm;

[0087] The power of the main etching is 450W, the pressure is 80mTorr, and the etching gas and its flow rate are respectively 50sccmCl 2 / 80sccmHBr;

[0088] The power of over-etching is 250W, the pressure is 120mTorr, and the etching gas and its flow rate are respectively 50sccmCl 2 / 80sccmHBr / 5sccmHe-O 2 .

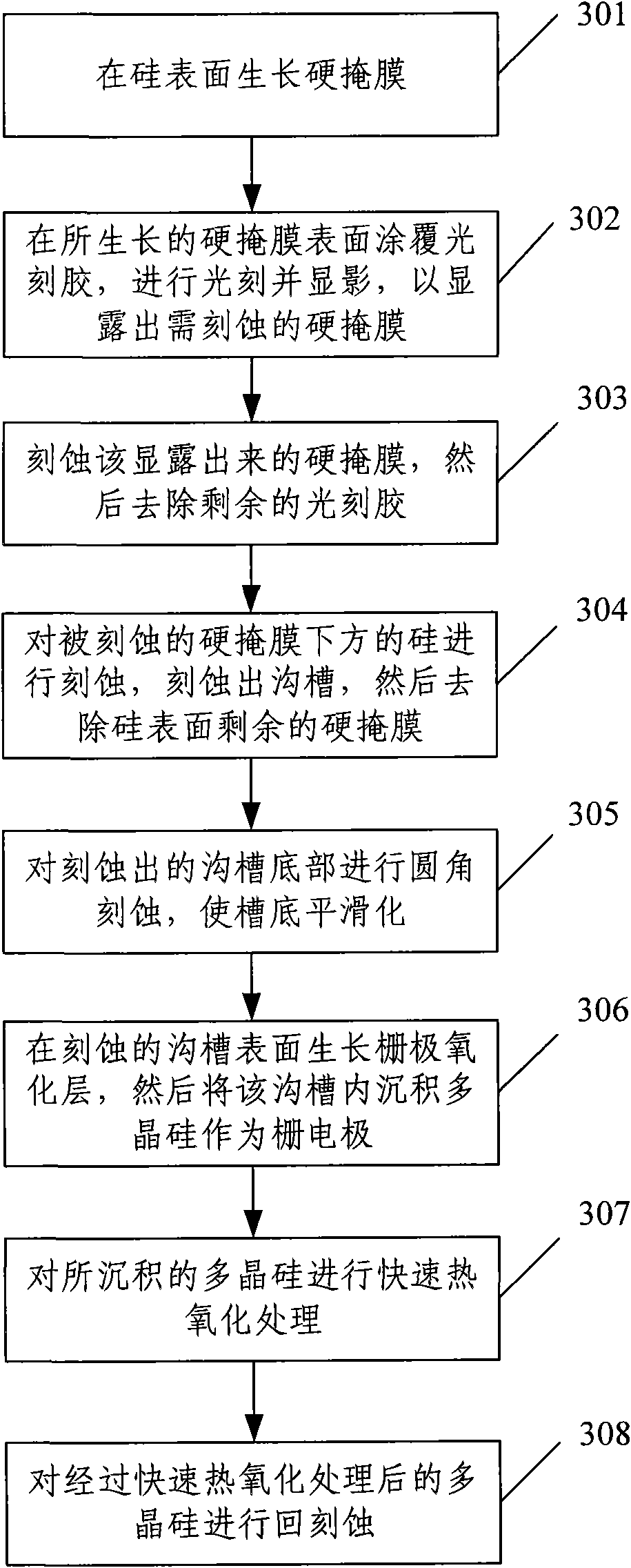

[0089] The method for planarizing the polysilicon surface of the present invention comprises the following steps:

[0090] c1) Using a high temperature process to grow silicon dioxide SiO on the surface of the single crystal silicon substrate 1 2 , to serve as hard mask 2, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching power | aaaaa | aaaaa |

| etching power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com