Overall lead-free X-ray shielding plastic compound material

A composite material and X-ray technology, which is applied in the field of rare earth mixed with other metals and compounds all lead-free X-ray shielding plastic composite materials, can solve the problems of poor compatibility, leakage of radiation, easy to pass through, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

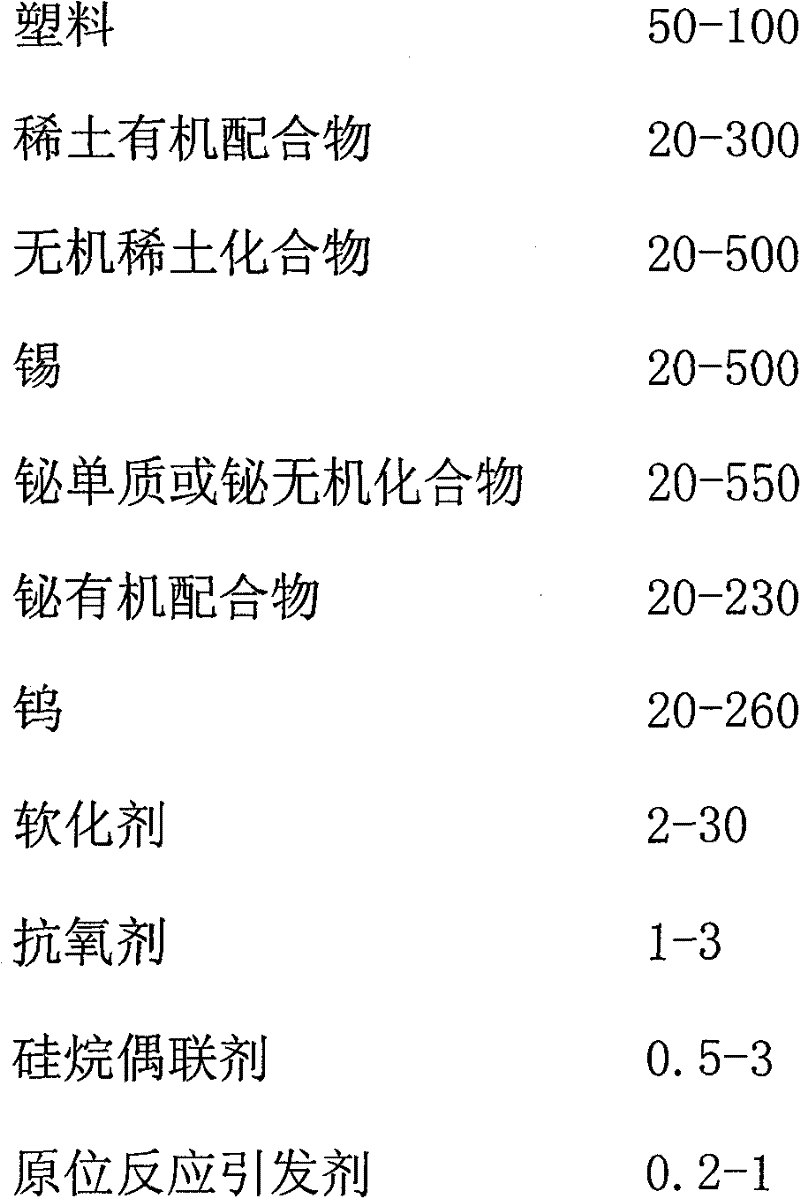

[0035] The composition and parts by weight of each component are:

[0036] Low-density polyethylene (LDPE) 100

[0038] Cerium methacrylate 40

[0039] Samarium methacrylate 40

[0044] Tin oxide 100

[0045] Bismuth oxide 100

[0046] Bismuth undecylenate 230

[0048] KH550 3

[0049] Low molecular weight polyethylene wax (molecular weight is 2000) 15

[0050] Antioxidant 1010 2

[0051] Dicumyl peroxide (in situ reaction initiator) 0.3

[0052] Preparation of shielding material: Heat the hot roll to 130°C, add 100 parts of LDPE and melt it to cover the roll, add 20 parts of samarium acrylate, 20 parts of terbium acrylate, 40 parts of samarium methacrylate, 40 parts of cerium methacrylate, After mixing 230 parts of bismuth undecylenate and 0.3 parts of in-situ reaction initiator dicumyl peroxide for 5 ...

Embodiment 2

[0055] The composition and parts by weight of each component are:

[0056] Low-density polyethylene (LDPE) 100

[0058] Gadolinium methacrylate 40

[0059] Samarium methacrylate 60

[0061] Gadolinium oxide 200

[0062] Cerium oxide 150

[0064] Tin oxide 120

[0065] Bismuth oxide 200

[0066] Bismuth methionate 150

[0067] Metal Tungsten 120

[0068] KH550 2

[0069] Low molecular weight polyethylene wax (molecular weight is 2000) 20

[0070] Antioxidant 1010 3

[0071] Dicumyl peroxide (in situ reaction initiator) 0.5

[0072] Preparation of shielding material: Heat the hot roll to 130°C, add 100 parts of LDPE and melt it to cover the roll, add 40 parts of cerium acrylate, 20 parts of holmium acrylate, 60 parts of samarium methacrylate, 40 parts of gadolinium methacrylate, After 150 parts of bismuth methacrylate and 0.5 parts of in-situ reaction initiator dicumyl peroxide were mix...

Embodiment 3

[0074] The composition and parts by weight of each component are:

[0075] Low-density polyethylene (LDPE) 100

[0076] Terbium acrylate 40

[0077] Cerium methacrylate 60

[0078] Samarium methacrylate 80

[0079] Gadolinium Acrylate 20

[0080] Neodymium oxide 150

[0081] Cerium oxide 150

[0082] Metal tin 150

[0083] Tin oxide 120

[0084] Bismuth oxide 100

[0085] Bismuth methionate 50

[0086] Metal Tungsten 150

[0087] KH550 2

[0088] Low molecular weight polyethylene wax (molecular weight is 2000) 20

[0089] Antioxidant 1010 2.5

[0090] Dicumyl peroxide (in situ reaction initiator) 0.8

[0091]Preparation of shielding material: Heat the hot roll to 130°C, add 100 parts of LDPE and make it melt to cover the roll, add 40 parts of terbium acrylate, 20 parts of gadolinium acrylate, 60 parts of cerium methacrylate, 80 parts of samarium methacrylate, After mixing 50 parts of bismuth methacrylate and 0.8 parts of in-situ reaction initiator dicumyl peroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com