Method for synthesizing chiral ferrocene diphosphine ligand

A technology of a chiral ferrocene and a synthesis method, which is applied to the synthesis field of chiral ferrocene bisphosphine ligands, can solve problems such as inconvenience in operation, and achieve the effects of simplified operation, high quality and meeting the requirements of industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The synthetic method of bisphosphine ligand is realized through the following steps:

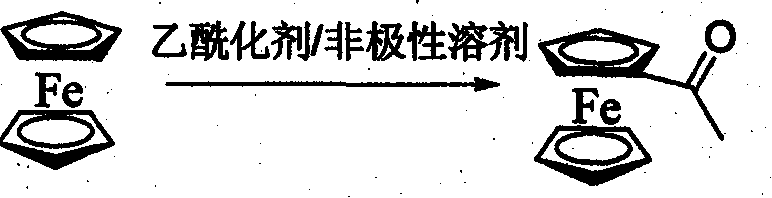

[0067] One) the synthesis of acetylferrocene (II)

[0068] Add 18.6g of ferrocene (I), 14g of aluminum trichloride, and 60ml of petroleum ether into a 250ml three-neck flask connected with mechanical stirring, reflux, and a dropping funnel, and start to slowly add 11ml of acetyl chloride dropwise, within about 30 minutes Drip finished. After reacting at 50°C for 4 hours, the reaction solution was poured into water, the organic layer was separated, the aqueous layer was extracted with the organic solvent dichloromethane, the organic layers were combined, dried, and concentrated to obtain about 21 g of pure acetylferrocene (II). The rate is 92%. The melting point is 83-85°C.

[0069] 1 H NMR (CDCl 3 ): δ4.77(s, 2H), 4.50(s, 2H), 4.21(s, 4H), 2.40(s, 3H); 13 C NMR (CDCl): δ 201.9, 79.0, 72.2, 69.7, 69.4, 27.2.

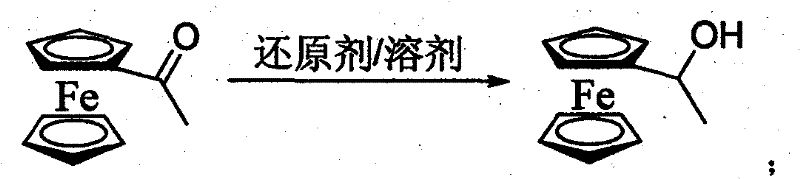

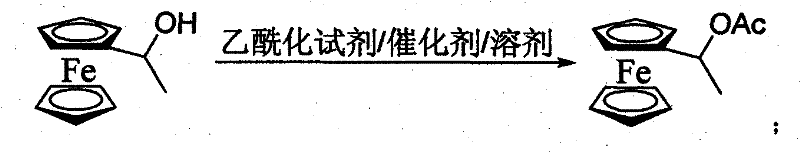

[0070] Two) the preparation of ferrocene alcohol (III)

[0071] Add ...

Embodiment 2

[0093] The synthetic method of bisphosphine ligand is realized through the following steps:

[0094] One) the synthesis of acetylferrocene (II)

[0095] Add 18.6g of ferrocene (I), 12g of aluminum oxide, and 60ml of dichloromethane into a 250ml three-neck flask connected with mechanical stirring, reflux, and a dropping funnel, and add 21ml of acetyl chloride dropwise within 30 minutes. After reacting at 60°C for 5 hours, pour the reaction solution into 100ml of water, separate the organic layer, extract the aqueous layer with the organic solvent dichloromethane, combine the organic layers, dry, and concentrate to obtain about 21.9g of pure acetylferrocene(II) , yield 96%. The melting point is 83-85°C.

[0096] 1 H NMR (CDCl 3 ): δ4.77(s, 2H), 4.50(s, 2H), 4.21(s, 4H), 2.40(s, 3H); 13 C NMR (CDCl): δ 201.9, 79.0, 72.2, 69.7, 69.4, 27.2.

[0097] Two) the preparation of ferrocene alcohol (III)

[0098] Add 21.9g of acetylferrocene(II), 38ml of methanol, and 2.3g of sodium...

Embodiment 3

[0120] The synthetic method of bisphosphine ligand is realized through the following steps:

[0121] One) the synthesis of acetylferrocene (II)

[0122] Add 18.6g of ferrocene (I), 13.6g of zinc chloride, and 60ml of toluene into a 250ml three-neck flask connected with mechanical stirring, reflux, and a dropping funnel, and slowly add 21ml of acetyl chloride dropwise within 30 minutes. After reacting at 60°C for 5 hours, the reaction solution was poured into 100ml of water, the organic layer was separated, the aqueous layer was extracted with the organic solvent methylene chloride, the organic layers were combined, dried, and concentrated to obtain about 22g of pure acetylferrocene(II). Yield 96.5%. The melting point is 83-85°C.

[0123]1 H NMR (CDCl 3 ): δ4.77(s, 2H), 4.50(s, 2H), 4.21(s, 4H), 2.40(s, 3H); 13 C NMR (CDCl): δ 201.9, 79.0, 72.2, 69.7, 69.4, 27.2.

[0124] Two) the preparation of ferrocene alcohol (III)

[0125] Add 2.28 g of acetylferrocene (II), 4 ml of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com