Smoking machine-mainstream flue gas cold trap integrated device and using method thereof

A mainstream smoke and smoking machine technology, applied in the field of cigarette manufacturing, can solve problems such as air leakage, poor heat exchange efficiency, and difficulty in ensuring the airtightness of the device, and achieve improved capture efficiency, sufficient condensation process, and improved repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

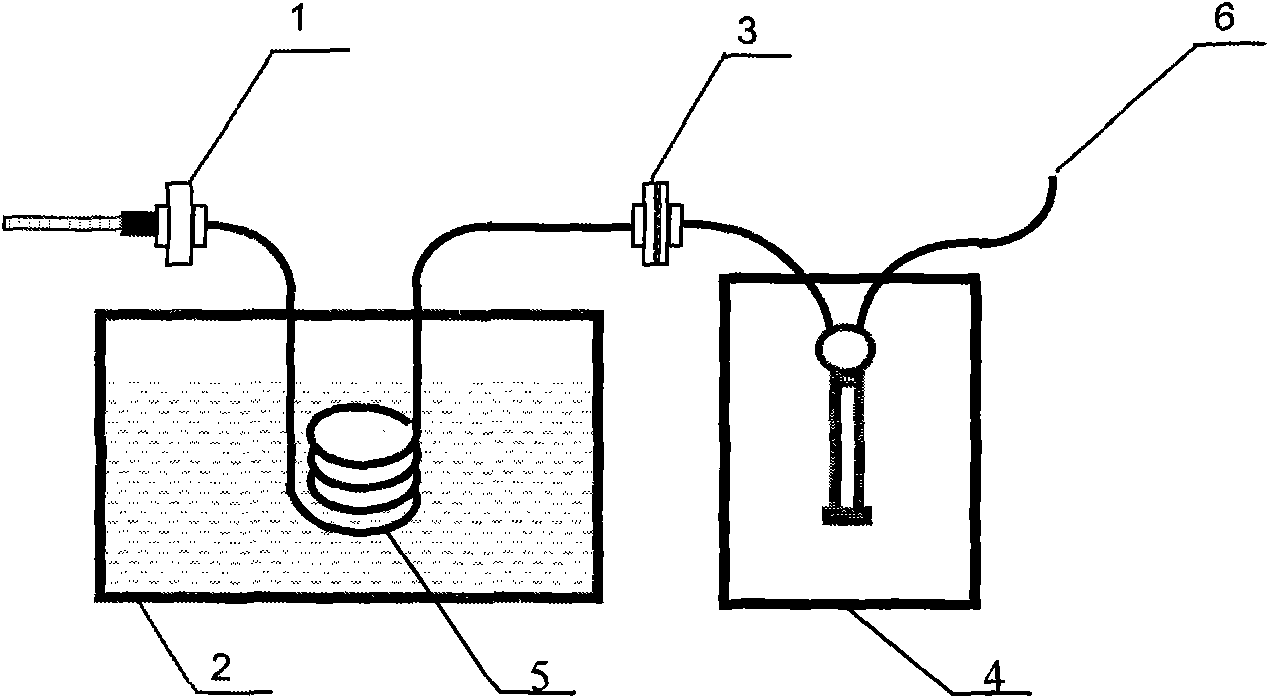

[0022] according to figure 1 The shown schematic diagram of the device is connected to the smoking machine-mainstream smoke cold trap trapping device, (the single-channel smoking machine of the present invention is a SP1-C1 type precision injection pump) and the single-port suction capacity is set to 35ml by the background software, and the suction The flow-time curve is a bell-shaped curve. Connect a soap foam flowmeter to the cigarette holder, and test the actual single-port suction capacity of the device at different cold trap temperatures. , -115°C, -196°C), the single-port suction capacity was tested, and the results are shown in Table 1 below:

[0023] Table 1

[0024] Cold trap temperature (℃)

[0025] It can be seen from the data in Table 1 that when the temperature of the cold trap is above -115°C, the single-port suction capacity of the device is basically consistent with that at room temperature, both within the standard range of 35±0.2ml / port. When the...

Embodiment 2

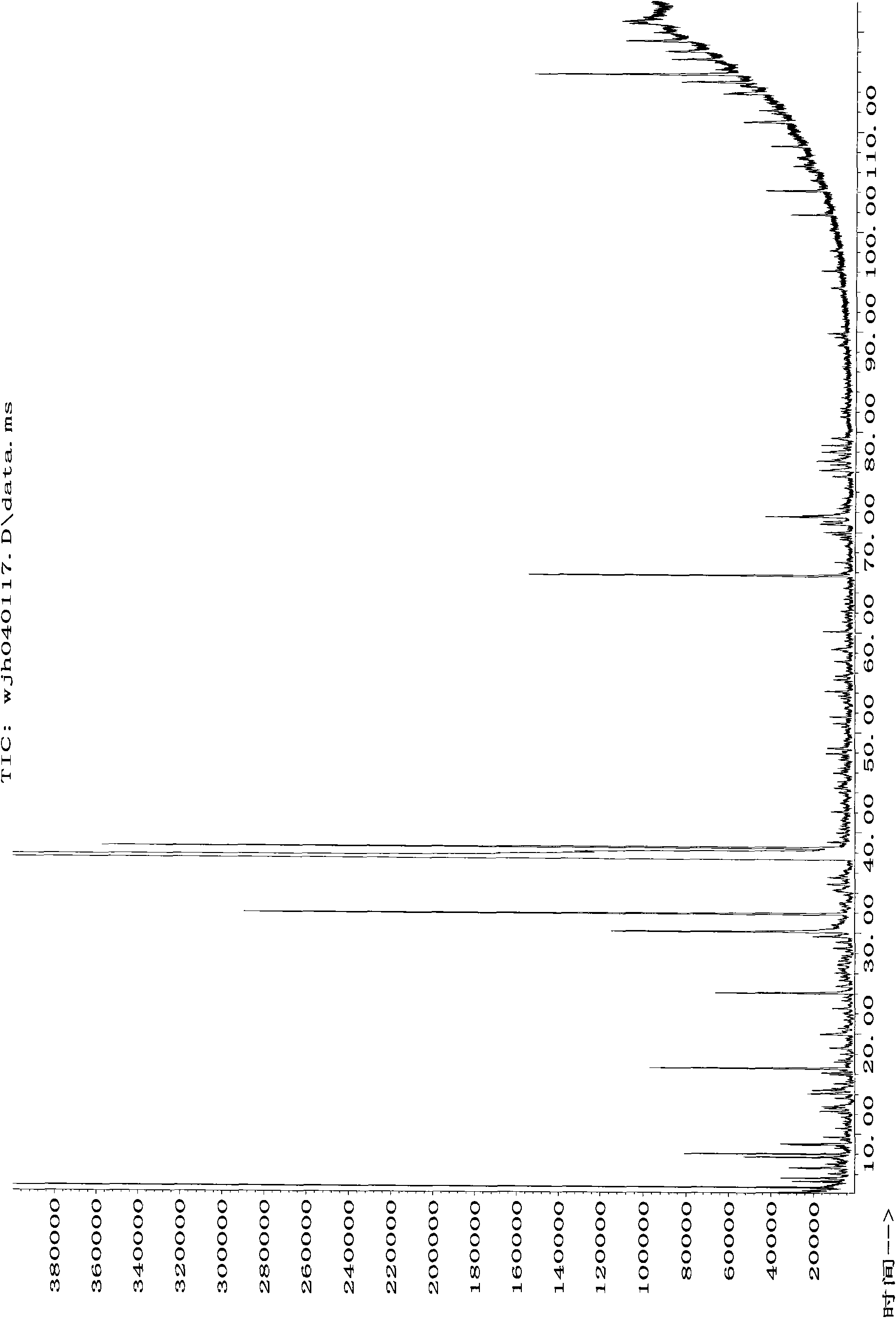

[0027] Smoking the temperature and humidity balanced and screened cigarettes according to the standard conditions, firstly use the Cambridge filter to capture the mainstream smoke of a cigarette, put the filter into a 1000ml round bottom flask, then add 350ml of pure water and about 100g of NaCl , shake well and put it into a voltage-controllable electric heating mantle for heating. At the same time, the other end of the distillation extraction device was connected to a 100ml flat-bottomed flask filled with 60ml of dichloromethane, and the flat-bottomed flask was placed in a water bath for heating, and the temperature of the water bath was adjustable. Heating both sides at the same time, timing after boiling, and distilling and extracting for 2 hours at the same time to obtain 60ml of dichloromethane extract. After the distillation and extraction are completed, add an appropriate amount of anhydrous sodium sulfate to the dichloromethane extract, add phenethyl acetate internal ...

Embodiment 3

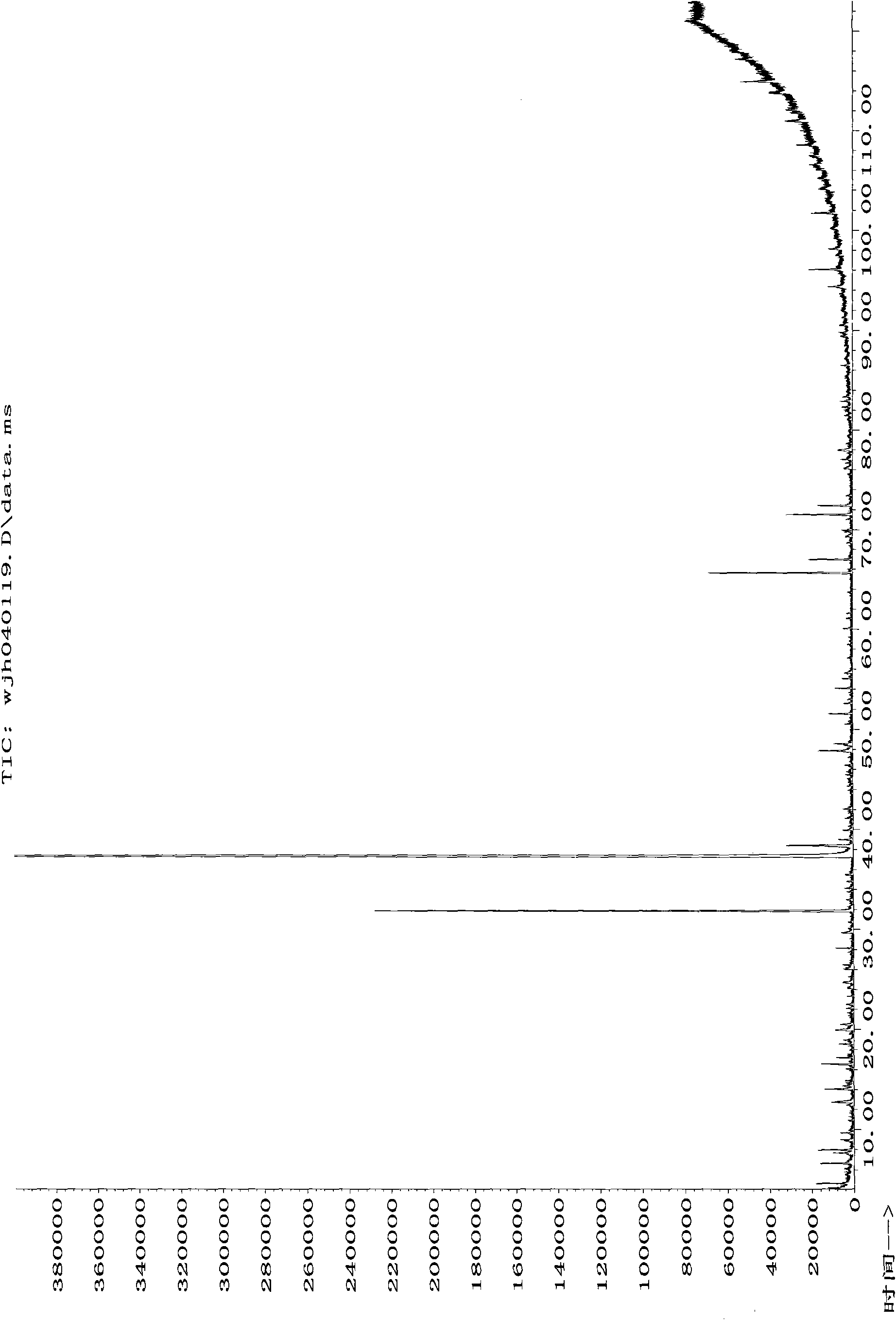

[0029]Smoking the temperature and humidity balanced and screened cigarettes according to the standard conditions, smoking 5 cigarettes each time, using the Cambridge filter to capture the particulate matter in the mainstream smoke, putting the filter into a 1000ml round bottom flask, adding 350ml pure Water and about 100g of NaCl are shaken well and put into a voltage-controllable electric heating mantle for heating. At the same time, the other end of the distillation extraction device was connected to a 100ml flat-bottomed flask filled with 60ml of dichloromethane, and the flat-bottomed flask was placed in a water bath for heating, and the temperature of the water bath was adjustable. Heating both sides at the same time, timing after boiling, and distilling and extracting for 2 hours at the same time to obtain 60ml of dichloromethane extract. Add an appropriate amount of anhydrous sodium sulfate to the dichloromethane extract, add phenethyl acetate internal standard solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com